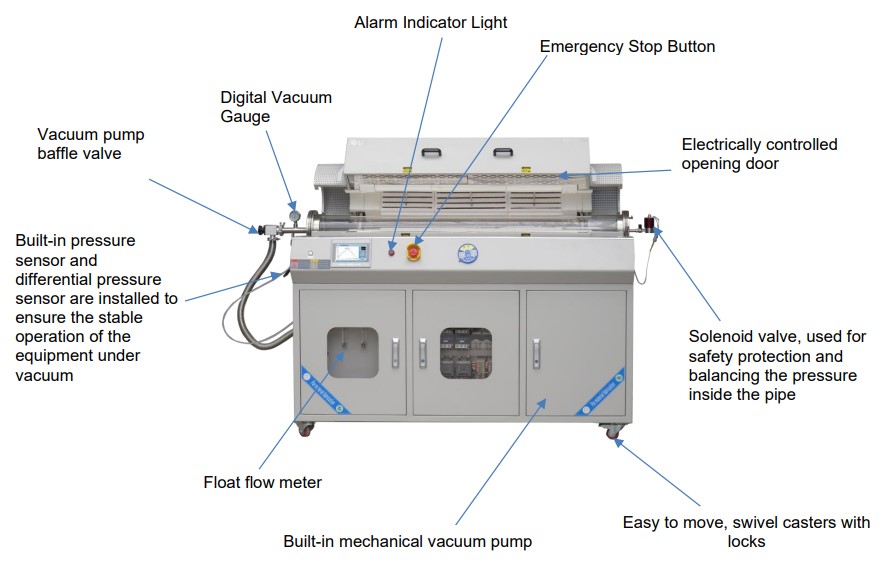

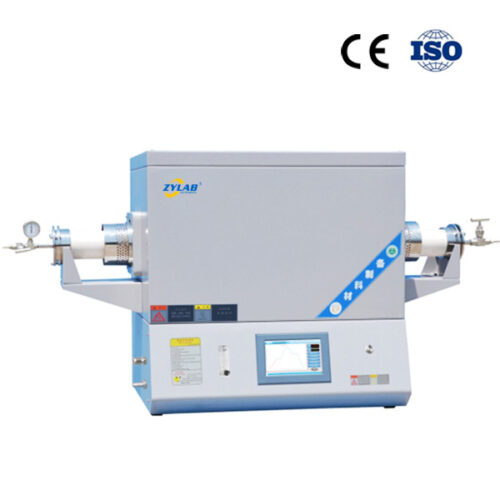

Large Size 3 Zone Tubular Furnace

Introduction:

In order to meet the requirements of various types of CVD processes, this smart 3 zone tubular furnace do not need to adjust each instrument separately.

Control instrument of multiple temperature zones are all integrated into the intelligent control system. All parameters will be setted through the touch screen. Multiple temperature zones set to the same temperature point, users can use as a single extended temperature zone. It continues the single-temperature zone tube furnace classic design, aesthetic and practical!

Features and Benefits of 3 Zone Tubular Furnace:

1. High purity quartz tube as furnace tube, Max. Temperature 1200.C(<1hour), continue working temperature Rt –1100.C.

2. 7”Color Touch screen LCD man-machine English interface, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

3. 30 segments programmable and auto control.

4. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

5. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

6. By using special lining import from Japan and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Ring heating, open structure, convenient observation for operator, able to meet rapid sintering of small sample

9. Come with gas flowmeter, atmosphere sintering more convenient.

10. Unique flange has a multi-function test holes, insert the corresponding electrode to test tube temperature or atmosphere environment.

11. Three temperature zones, and each temperature zone can operate independently.

12. Can add modules to contol and download data remotely(optional).

13. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for material research labs, also used in factory for small production.

Main Technical Parameters of 3 Zone Tubular Furnace:

| No. | Type | Technical Parameters | |

| Heating system

|

1 | Furnace dimensions | L×W×H=1700mm×760mm×1200mm |

| 2 | Reaction chamber dimensions | High-purity quartz, outer diameter 120mm, inner diameter 112mm*(200+400+200)mm, tube length 1400mm | |

| 3 | Main control working temperature | ≤1150℃ | |

| 4 | Opening method | Electrically open or close the furnace chamber through screen buttons for easy viewing of sample position and replacing the furnace tube | |

| 5 | heating rate | Recommended ≤20℃/min | |

| 6 | heating element | HRE (High-Resistance Element) | |

| 7 | furnace chamber material | Alumina fiber insulation refractory material | |

| 8 | temperature zone length | 200+400+200mm | |

| 9 | Temperature control accuracy | ±1℃ | |

| 10 | Sealing method | Self-sealing, with temperature measurement hole and handheld thermometer | |

| 11 | Temperature measurement element | 3 sets of K-type thermocouples for more uniform temperature control (three-zone temperature control)

Provide the ability to set a thermal profile for each heating zone |

|

| Gas system configuration | 12 | Flow meter | 2-channel float flow meter (0.1-1.5L/min, 20-200ml/min) |

| 13 | Pressure gauge | Mechanical vacuum pressure gauge | |

| 14 | Regulating valve | Manual regulating valve | |

| 15 | Pipeline connection method | Double-card sleeve PTFE tubing connection(φ6.35) | |

| 16 | Pressure range | -0.1-0.15Mpa (absolute pressure) | |

| Opening system | 17 | Transmission mode | Lever transmission |

| 18 | Motor | DC linear actuator motor | |

| 19 | Sensor type | Two sets of displacement sensors to prevent loss of control | |

| Vacuum system | 20 | Vacuum pump | Mechanical vacuum pump: Direct-drive rotary vane vacuum pump (two-stage rotary vane)

|

| 21 | Pumping rate | 9.9(m³/H) | |

| 22 | Inlet/outlet connection | KF25(mm) | |

| 23 | Motor speed | 1440(rpm) | |

| 24 | Ambient Temperature | 5~40℃ | |

| 25 | Noise level (dB) | ≤56 | |

| 26 | Vacuum gauge | Digital vacuum gauge, capable of digitally displaying the pressure inside the furnace tube | |

| 27 | Vacuum level | 5-10Pa | |

| 28 | Pressure sensor | Displays positive pressure inside the tube and allows for setting of overpressure alarms | |

| 29 | Differential pressure sensor | Maintains a certain pressure difference inside the tube | |

| Control system | 35 | Control mode | Embedded operating system with graphical interface in both Chinese and English, 7-inch color touchscreen input, intelligent human-machine dialogue mode |

| 36 | Temperature curve setting | can store up to 15 temperature curves, each curve can be set with 30 segments of “time-temperature curve,” real-time monitoring, dynamically displaying the “time-temperature curve” | |

| 37 | Temperature calibration | Non-linear correction of the temperature difference between the temperature control temperature and the sample temperature throughout the system | |

| 38 | Equipment operation time recording | Sintering data storage, automatic report generation, real-time recording and retrieval | |

| 39 | System protection | Over-temperature alarm, over-current protection, open circuit prompt | |

| Others | 40 | Electrical specifications | AC208-380V 50/60HZ(as required) 8KW |

| 41 | Included accessories | 1 furnace tube, 1 set of sealing flanges, 1 user manual, miscellaneous tools, etc. | |

| 42 | Warranty | 12 months warranty for the equipment, 24 months for the touchscreen system, lifetime support. |

Optional:

Additional tubes: high purity quartz tube Dia 120*1400mm

Quartz stands: quartz curcible(as requirement)

Applications:

Large size 3 zone tubular furnaces find applications across various industries and research fields due to their ability to provide controlled heating environments over long lengths. Here are some common applications:

Material Synthesis and Processing

Tubular furnaces are extensively used in material synthesis processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and thermal evaporation. They enable precise control over temperature gradients, atmosphere, and heating rates, crucial for producing high-quality materials like nanoparticles, thin films, and nanowires.

Advanced Materials Research

In research laboratories, tubular furnaces are employed for studying the properties and behaviors of advanced materials such as ceramics, composites, and carbon-based materials. Researchers can simulate various thermal environments to investigate phase transitions, crystal growth, and other material phenomena.

Heat Treatment and Annealing

Industries like metallurgy and semiconductor manufacturing utilize tubular furnaces for heat treatment processes such as annealing, brazing, and sintering. These processes involve heating materials to specific temperatures and holding them at those temperatures for controlled durations to achieve desired material properties or microstructural changes.

Chemical Reactions and Catalysis Studies

Tubular furnaces are integral in conducting chemical reactions at elevated temperatures for catalysis studies and chemical synthesis. They provide a controlled environment to investigate reaction kinetics, catalyst performance, and reaction mechanisms, essential for developing new processes and improving existing ones.

Graphene Production

Tubular furnaces are commonly used in the production of graphene, a two-dimensional carbon allotrope with unique properties. Techniques such as chemical vapor deposition (CVD) utilize tubular furnaces to grow graphene layers on various substrates by decomposing carbon-containing gases at high temperatures.

Crystallization and Crystal Growth

In fields like crystallography and semiconductor research, tubular furnaces are employed for crystallization and crystal growth processes. By precisely controlling temperature gradients and growth conditions, researchers can grow large, high-quality crystals essential for various applications including electronics, optics, and photonics.

Laboratory Scale Testing

Tubular furnaces serve as versatile tools in research laboratories for conducting experiments across disciplines such as materials science, chemistry, and physics. They enable researchers to explore a wide range of temperature-dependent phenomena, facilitating fundamental research and innovation.

Solar Cell Fabrication

Tubular furnaces play a role in the fabrication of solar cells, particularly in processes like diffusion, deposition, and annealing of semiconductor materials. These processes are critical for optimizing the performance and efficiency of solar cell devices.

Carbonization and Pyrolysis

Tubular furnaces are utilized in carbonization and pyrolysis processes to convert organic materials into carbonaceous products. This is important in various industries, including carbon fiber production, waste treatment, and energy conversion.

Powder Metallurgy

In powder metallurgy, tubular furnaces are used for processes such as powder compaction, sintering, and alloying. These processes involve heating powdered metals to high temperatures to form dense, solid components with specific mechanical and physical properties.