High-Precision Horizontal 3-Zone Gradient Furnace

Introduction

In order to meet the requirements of various types of CVD processes, this smart 3-Zone Gradient Furnace do not need to adjust each instrument separately.

Control instrument of multiple temperature zones are all integrated into the intelligent control system. All parameters will be setted through the touch screen. Multiple temperature zones set to the same temperature point, users can use as a single extended temperature zone. It continues the single-temperature zone tube furnace classic design, aesthetic and practical!

Key Features

1. High purity quartz tube as furnace tube, Max. Temperature 1200.C(<1hour), continue working temperature Rt –1100.C.

2. 7”Color Touch screen LCD man-machine English interface, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

3. 30 segments programmable and auto control.

4. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

5. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

6. By using special lining import from Japan and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Ring heating, open structure, convenient observation for operator, able to meet rapid sintering of small sample

9. Come with gas flowmeter, atmosphere sintering more convenient.

10. Unique flange has a multi-function test holes, insert the corresponding electrode to test tube temperature or atmosphere environment.

11. Three temperature zones, and each temperature zone can operate independently.

12. Can add modules to contol and download data remotely(optional).

13. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for material research labs, also used in factory for small production.

Technical Specifications of 3-Zone Gradient Furnace

| Model | O1200-IIIT |

| Chamber Model | Open |

| Chamber Material | Imported high quality alumina fiber refraction insulation |

| Heating Element | High quality alloy heating wire |

| Max.temperature | 1200.C |

| Continue Working Temperature | 300~1150.C |

| Heating Rate | 1℃/H-20℃/Min |

| Heating Zone | Three(3 zones), each temperature zone can operate independently |

| Length of Heating Zone | 100+200+100mm(optional: 200+400+200mm) |

| Tube Material | High purity quartz |

| Tube Sizes | Φ50×1000(mm)

Other optional sizes: Φ50×1400(mm) Φ60×1400(mm) Φ80×1400(mm) Φ100×1400(mm) |

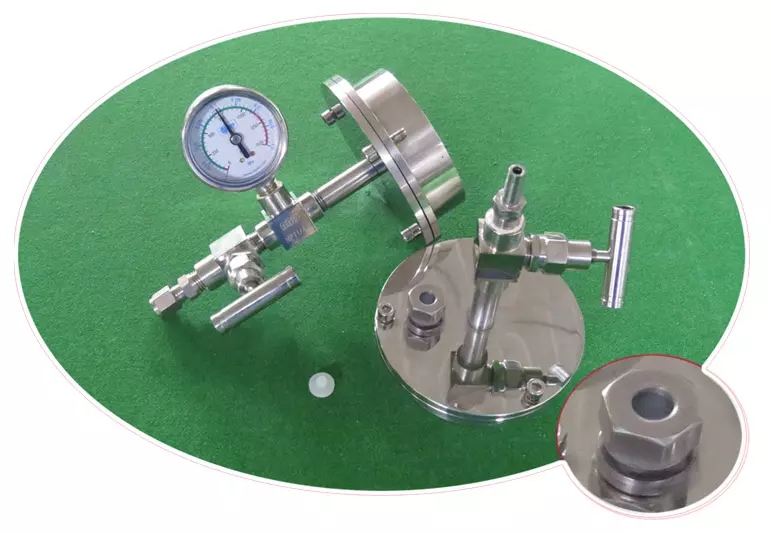

| Sealing Mode | High Quality Stainless Steel Vacuum Flange |

| Vacuum | ≤10Pa |

| Control Mode | Smart PID Control — 7″ Intelligent Touch Screen Controller

|

| Operating Interface | English Graphical Interface |

| Temperature Accuracy | +/- 1.C |

| Presetting Curve | 15 Presetting Curve, 30 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Protection |

| Thermocouple | K Type |

| Power Supply | AC208-240V 50/60HZ, 2.6KW |

| Standard Accessories | Quartz Tube, Vacuum Flange, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

| Certificate | CE, ISO |

| Warranty | 12 months(not including consumable parts, such as quartz tube, heating elements, thermocouple), lifetime support. |

Which kinds of industry can use this 3-Zone Gradient Furnace?

Materials Science, Metallurgy, Semiconductor, Energy Research, Chemical Processing, Geosciences, Aerospace, Biomedical, University Labs, & R&D Centers,etc

Applications of 3-Zone Gradient Furnace

1. Thermal Analysis: Studying phase transitions and material behavior.

2. Material Synthesis: Creating ceramics, composites, and advanced materials.

3. Heat Treatment: Annealing, sintering, and crystal growth.

4. Wafer Processing: Annealing and doping in semiconductor manufacturing.

5. Battery Research: Developing solid-state batteries and catalyst activation.

6. CVD and Coating: Thin film deposition and material modification.

7. Geoscience Experiments: Simulating mineral formation and thermal gradients.

8. High-Temperature Testing: Evaluating heat-resistant materials.

FAQ

1. What is a 3-Zone Gradient Furnace?

A 3-Zone Gradient Furnace is a high-temperature furnace designed with three separate heating zones, allowing precise control of temperature gradients. It’s used for various applications such as material synthesis, heat treatment, and thermal testing, ensuring uniform heating and consistent results.

2. Can the 3-Zone Gradient Furnace be customized for specific needs?

Yes! The furnace can be customized with various features such as:

Different temperature ranges

Additional atmosphere control for specific materials

Size adjustments to fit various lab or industrial spaces

3. What is the typical temperature range of the 3-Zone Gradient Furnace?

The temperature range typically varies between 300 and 1150°C.

4. Is the 3-Zone Gradient Furnace easy to operate?

Yes, the furnace comes with an intelligent PLC control system that is user-friendly and easy to operate, with a touchscreen interface for managing temperature settings and other parameters.

Click to see more content:

Understanding Tube Furnace Temperatures: Medium vs. High-Temperature Applications

For More Options on Tube Furnaces

Click here [Tube Furnaces Collection]

For More Options on High Temperature Furnaces

Click here [High Temperature Furnaces Collection]