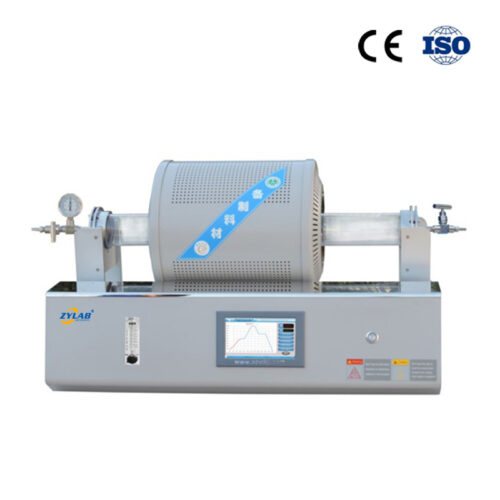

1700.C Small Tube Furnace

Introduction:

This 1700.C Small Tube Furnace max.temperature up to 1700.C, use corundum tube as the carrier for heating and sealing. Precise and advanced touch screen auto temperature controller, high temperature accuracy, easy operation, excellent heat-insulation effect, symmetrical temperature uniform.

Is widely used for vacuum sintering, vacuum sintering under atmosphere protection, nano materials preparation, battery material preparation and other multiple research fields.

Main Features:

1.Max. Temperature 1700.C, suggest working temperature 800-1650.C.

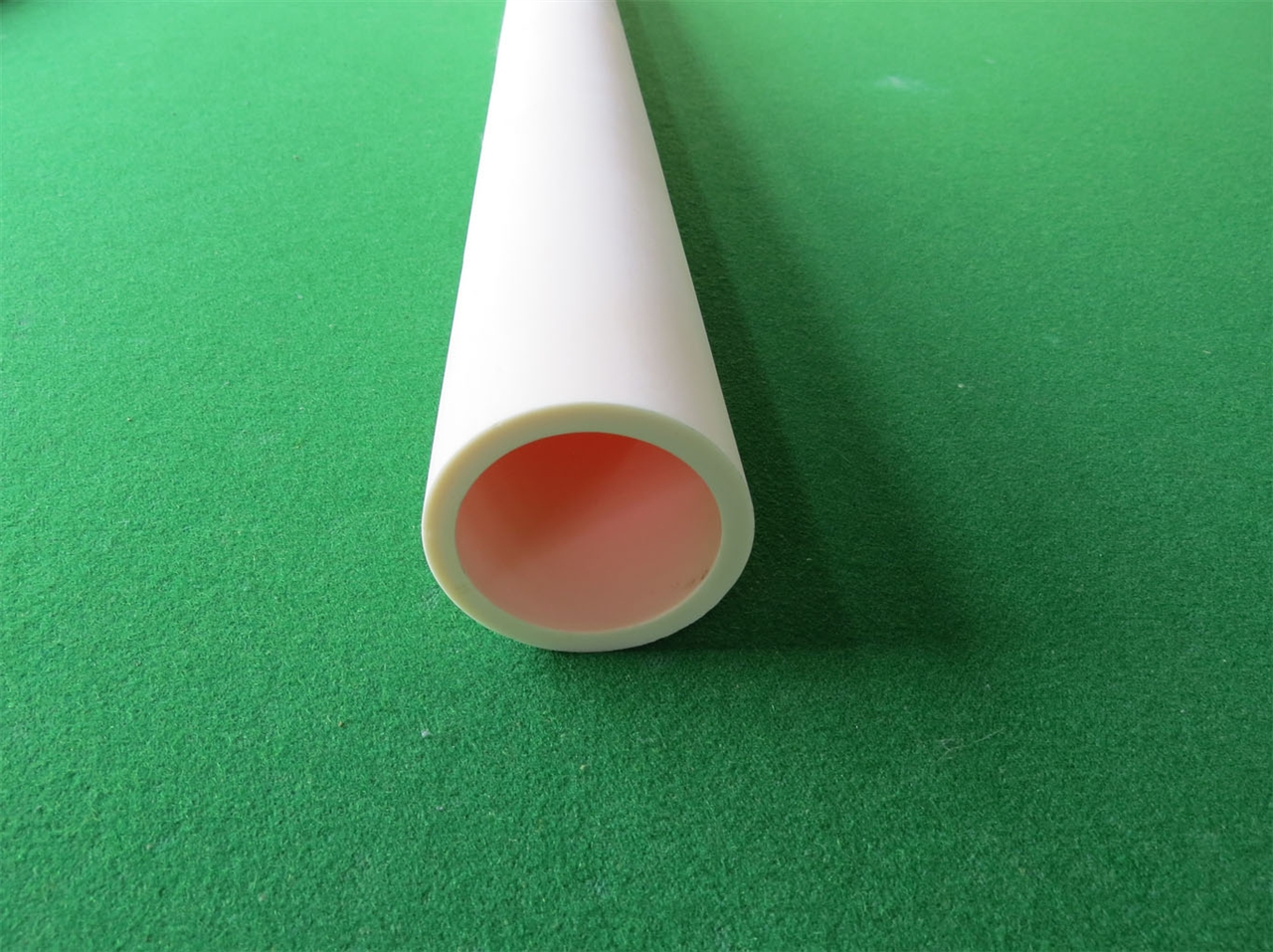

2.High purity alumina(Corundum tube as furnace tube, with excellent corrosion resistance and high temperature resistance, longer service life.

3. 30 segments programmable and auto control.

4. Intelligent 7”Color Touch screen LCD man-machine English interface temperature controller, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

5. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

6. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

7. By using special lining import from Japan and high quality heating elements made of pure type molydenum disilicide, protected against chemical contamination at the best and longer service life.

8. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

9. Come with gas flowmeter, atmosphere sintering more convenient.

10. Unique flange has a multi-function test holes, insert the corresponding electrode to test tube temperature or atmosphere environment.

11. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for labs and production in factory.

Main Specifications:

| Model | T1700-IT |

| Chamber Material | Imported high quality alumina fiber refraction insulation |

| Heating Element | High purity mosi2 rod |

| Max.temperature | 1700.C |

| Working Temperature | ≤1650.C |

| Heating Rate | ≤20.C /min(advice:10.C/min) |

| Heating Zone | One(optional:two) |

| Length of Heating Zone | 180m |

| Constant temperature Zone | 130mm |

| Tube Material | High Purity Alumina(Corundum tube) |

| Tube Size(mm) | Dia50x700mm

Other optional size: Φ50*1000,Φ60*1000,Φ80*1000(heating length 310mm) Φ50*1200,Φ60*1200,Φ80*1200(heating length 480mm) |

| Sealing Mode | Vacuum Flange |

| Vacuum | ≤ 10pa |

| Control Mode | Smart PID Control |

| Temperature Accuracy | +/- 1.C |

| Operating Interface | English Graphical Interface |

| Presetting Curve | 15 Presetting Curve, 30 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Prompt |

| Thermocouple | B Type |

| Power | 1.8kw |

| Working Voltage | 208-240V 50/60HZ |

| Dimensions | 850x680x420mm |

| Standard Accessories | Alumina Tube, Vacuum Flange,Vacuum Gauge, Gas Flow Meter,Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

| Warranty | 18 months(not including consumable parts, such as alumina tube, heating elements, thermocouple, etc), lifetime support. |

| Certification | CE,ISO |

Which kinds of industry can use this 1700.C Small Tube Furnace?

College & Universities, New Material Research, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics, Ceramic, etc.

Applications:

Widely used for vacuum sintering, vacuum sintering under atmosphere protection, nano materials preparation, battery material preparation and other multiple research fields.

Used in university laboratories, research institutes, and industrial & mining enterprise laboratories for sintering of metal ceramic materials, heat treatment of small steel parts, and quality testing.

In analytical chemistry industry, mainly used for sample treatment in water qualiy analysis, environmental analysis and other fields. It can also be used for oil and its analysis.

For heat working or treatment of small workpieces in cement and building materials industries.

Used in the pharmaceutical industry for drug inspection, pre-treatment of medical samples,etc.

In the coal mining industry for measuring moisture, ash, volatile matter, ash melting point analysis, ash composition analysis, and elemental analysis,etc.

Click to see more content:

Understanding Tube Furnace Temperatures: Medium vs. High-Temperature Applications

The Role of 1700°C Tube Furnace in Material Preparation