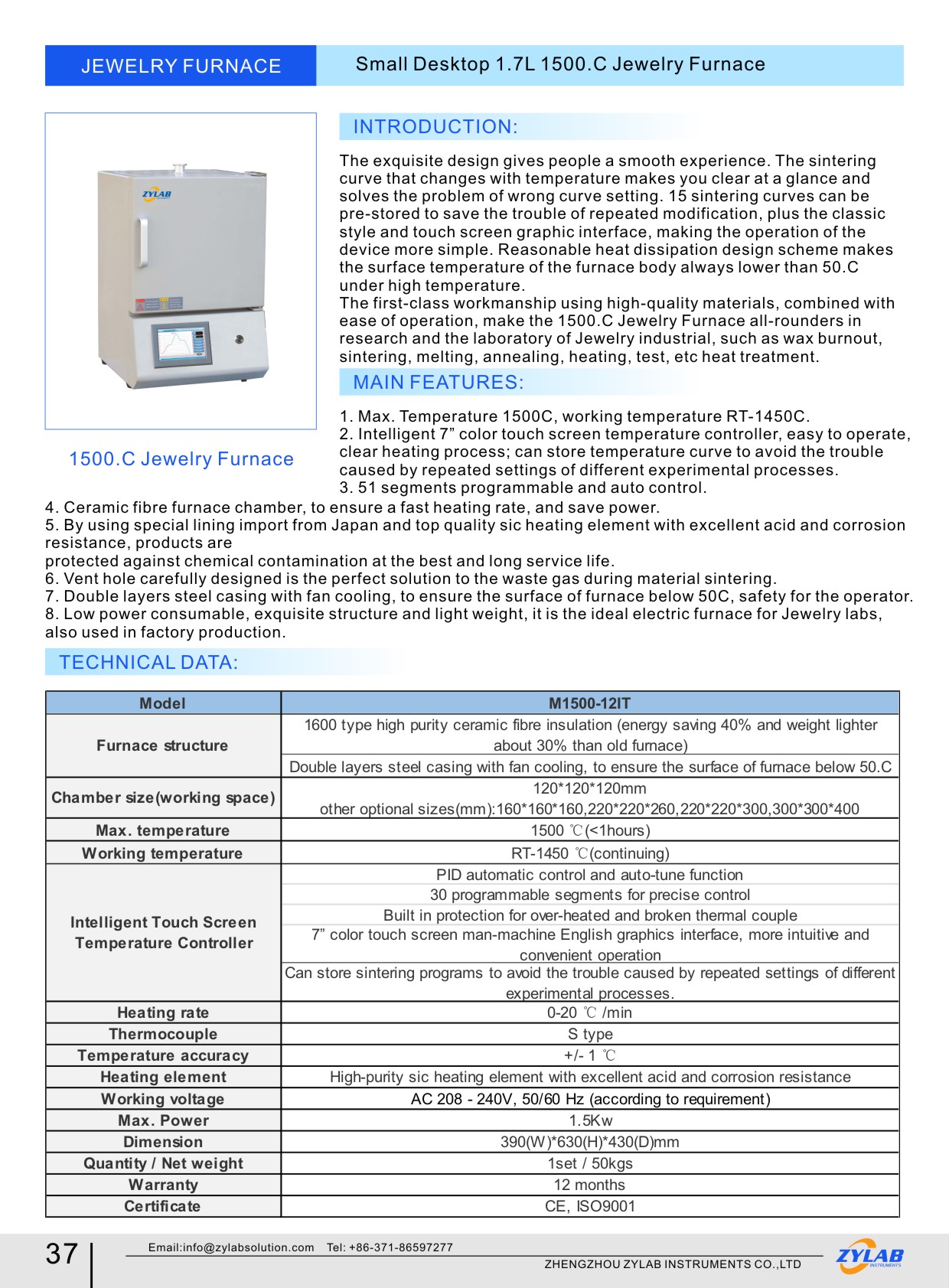

Small Desktop 1500.C Jewelry Furnace

Introduction:

The first-class workmanship using high-quality materials, combined with ease of operation, make the 1500.C Jewelry Furnace all-rounders in research and the laboratory of Jewelry industrial, such as wax burnout, sintering, melting, annealing, heating, testing, etc heat treatment.

The exquisite design gives people a smooth experience. The sintering curve that changes with temperature makes you clear at a glance and solves the problem of wrong curve setting. 15 sintering curves can be pre-stored to save the trouble of repeated modification, plus the classic style and touch screen graphic interface, making the operation of the device more simple. Reasonable heat dissipation design scheme makes the surface temperature of the furnace body always lower than 50.C under high temperature.

Main Features:

1. Max. Temperature 1500C, working temperature RT-1450C.

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and auto control.

4. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

5. By using special lining import from Japan and top quality sic heating element with excellent acid and corrosion resistance, products are protected against chemical contamination at the best and long service life.

6. Vent system carefully designed is the perfect solution to the waste gas during material sintering.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50C, safety for the operator.

8. Low power consumable, exquisite structure and light weight, it is the ideal muffle furnace for material research labs, also used in factory production.

Main Specifications:

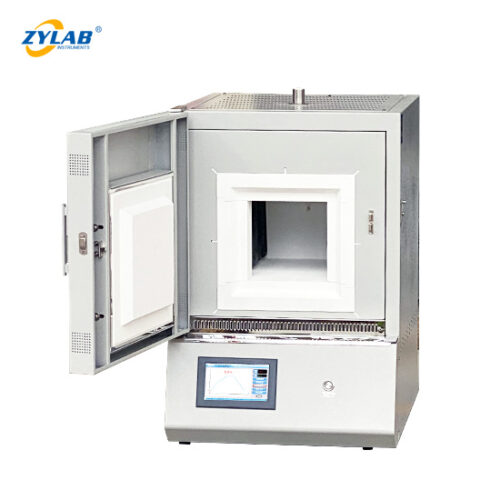

| Model | M1500-12IT |

|

Furnace structure |

•1600 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

120*120*120mm

Also supply other sizes:160*160*160mm, 220*220*260mm, 220*220*300mm, 300*300*400mm. |

| Max. temperature | 1500.C(<1hours) |

| Working temperature | RT-1450.C(continuing) |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control via SCR. •30 programmable segments for precise control of heating rate, cooling rate and dwell time. •Build in PID auto-tune function with overheating and broken thermocouple broken protection, over temperature protection and alarm allows for operation without attendant. •Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. •Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes. |

| Heating rate | 0-20.C /min |

| Thermocouple | S type |

| Temperature accuracy | +/- 1.C |

| Heating element | High-purity sic heating element with excellent acid and corrosion resistance |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 1.5Kw |

| Dimension | 390(W)*630(H)*430(D)mm |

| Quantity / Net weight | 1set / 50kgs |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. |

| Certificate | CE, ISO9001 |

Applicatons of 1500°C jewelry furnace:

1500°C jewelry furnace is a high-temperature furnace specifically designed for jewelry making and related processes. Here are some common applications of a 1500°C jewelry furnace:

Casting

Jewelry casting involves melting metal alloys (such as gold, silver, platinum, or brass) and pouring them into molds to create jewelry pieces. A 1500°C jewelry furnace provides the high temperatures necessary to melt these metals efficiently and create intricate designs.

Investment Casting

Investment casting, also known as lost-wax casting, is a process used to create detailed metal parts or jewelry from wax patterns. The wax patterns are invested in a refractory material, and then the wax is melted out in the furnace, leaving behind a cavity that is filled with molten metal.

Annealing

Annealing is a heat treatment process used to soften metals and relieve internal stresses. Jewelry pieces that have been formed or soldered may undergo annealing in a 1500°C furnace to improve their ductility, reduce brittleness, and enhance their workability.

Sintering

In jewelry making, sintering is the process of fusing metal particles together to form a solid mass. This process is often used in the production of metal clay jewelry and 3D-printed metal jewelry components. A 1500°C furnace can provide the high temperatures required for sintering metal powders or clay.

Enameling

Enameling is a decorative technique used to apply a vitreous coating to metal surfaces. Jewelry pieces are heated in a 1500°C furnace to fuse powdered glass onto the metal substrate, creating vibrant and durable enamel designs.

Glass Fusing

Some jewelry designs incorporate fused glass elements. Glass fusing involves heating glass pieces in a kiln until they melt and fuse together. A 1500°C furnace can be used to achieve the temperatures necessary for glass fusing in jewelry making.

Metal Alloying

Jewelry alloys are created by combining different metals to achieve desired properties such as color, hardness, or durability. A 1500°C furnace can be used to melt and alloy metal ingots, allowing jewelry makers to create custom alloy compositions for specific applications.

Heat Treatment

Heat treatment processes such as quenching, tempering, or aging may be required to achieve specific mechanical or metallurgical properties in jewelry components. A 1500°C furnace can provide precise temperature control for performing these heat treatment operations.

Overall, a 1500°C jewelry furnace is a versatile tool that enables jewelry makers to carry out a wide range of processes, from melting metals and fusing glass to annealing and heat treating jewelry components, thereby facilitating the creation of intricate and high-quality jewelry pieces.

Benefits of 1500°C jewelry furnace:

M1500-12IT 1500°C jewelry furnace offers numerous benefits for jewelry makers and manufacturers. Here are some key advantages:

High Temperature Capability

The ability to reach temperatures up to 1500°C allows for efficient melting of precious metals such as gold, silver, platinum, and their alloys. This enables the production of intricate and detailed jewelry pieces with precise casting and molding requirements.

Precision Control

M1500-12IT 1500°C jewelry furnace is equipped with advanced temperature control systems, ensuring precise and consistent heating profiles. This level of control is essential for achieving desired metallurgical properties and ensuring uniform heating throughout the jewelry casting process.

Versatility

M1500-12IT 1500°C jewelry furnace can accommodate a wide range of jewelry-making processes, including casting, annealing, enameling, sintering, and glass fusing. Its versatility makes it suitable for various jewelry production techniques, allowing jewelers to create diverse designs and styles.

Increased Productivity

With rapid heating capabilities and efficient temperature management, M1500-12IT 1500°C jewelry furnace can help increase production throughput and reduce cycle times. This leads to improved productivity and shorter lead times for jewelry manufacturing operations.

Quality Assurance

Consistent and controlled heating provided by a 1500°C furnace helps minimize casting defects, such as porosity, shrinkage, and surface irregularities. This results in higher-quality jewelry pieces with superior finish and aesthetic appeal.

Cost Efficiency

By optimizing energy consumption and reducing material wastage, a 1500°C jewelry furnace contributes to cost savings in jewelry production. Its efficient operation and precise temperature control help minimize rework and scrap, resulting in improved profitability for jewelry manufacturers.

Customization

Jewelers can use a 1500°C furnace to create custom alloys, experiment with new casting techniques, and develop unique jewelry designs. The flexibility offered by the furnace allows for customization according to customer preferences and market trends.

Durability and Reliability

High-quality construction materials and robust design ensure the durability and reliability of a 1500°C jewelry furnace, even under demanding operating conditions. This minimizes downtime and maintenance costs, contributing to long-term efficiency and profitability.

Safety

M1500-12IT 1500°C jewelry furnace is equipped with safety features such as thermal insulation, overheat protection, and automatic shut-off systems. These features help ensure safe operation and protect both equipment and personnel from potential hazards.

Overall, M1500-12IT 1500°C jewelry furnace offers numerous benefits, including high temperature capability, precision control, versatility, increased productivity, quality assurance, cost efficiency, customization options, durability, reliability, and safety, making it an indispensable tool for jewelry makers and manufacturers.