1500.C Chamber Furnace

Introduction:

Big capacity 36L 1500.C chamber furnace adopts durable compact vertical structure, without auxiliary table, convenient operation.

The tilting angel of operating panel is 43, excellent user experiences.

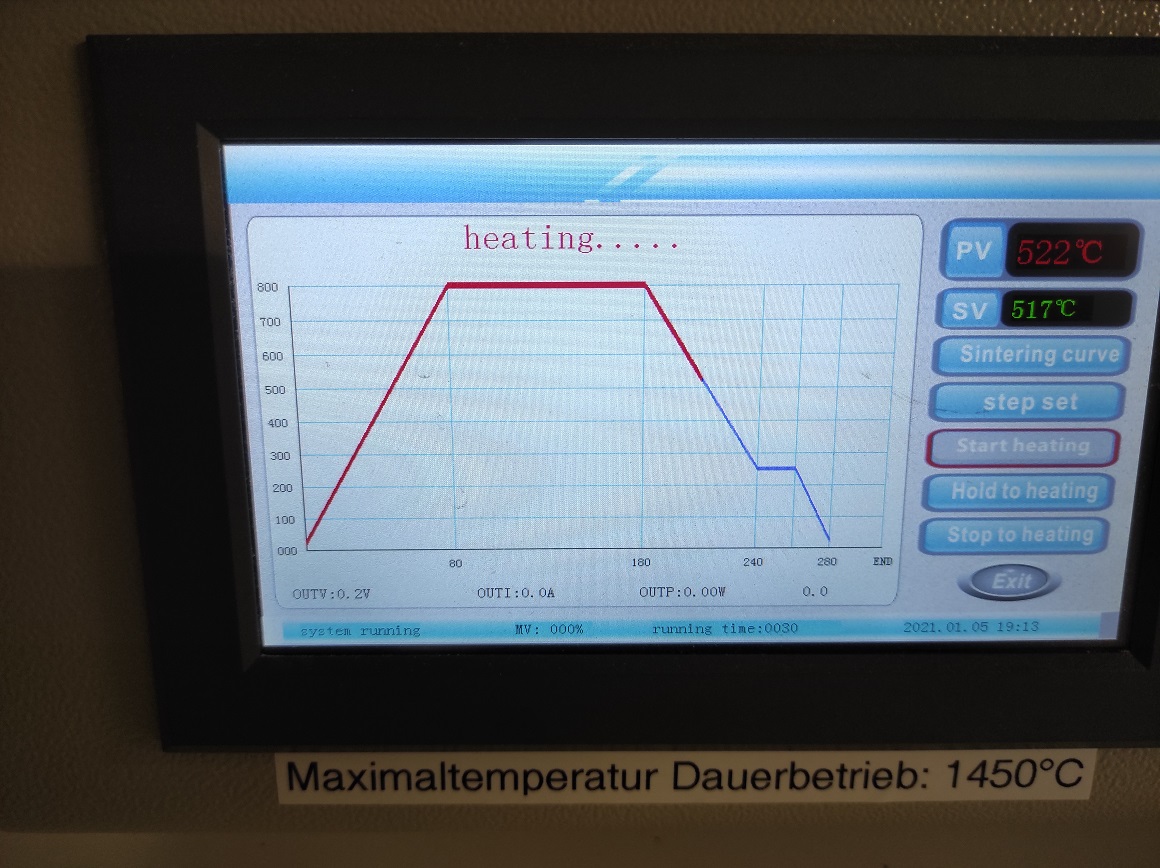

The exquisite design gives people a smooth experience. The sintering curve that changes with temperature makes you clear at a glance and solves the problem of wrong curve setting. 15 sintering curves can be pre-stored to save the trouble of repeated modification, plus the classic style and touch screen graphic interface, making the operation of the device more simple. Reasonable heat dissipation design scheme makes the surface temperature of the furnace body always lower than 50.C under high temperature.

Main Features:

1. Max. Temperature 1500.C, working temperature Rt –1450.C.

2. 30 segments programmable, auto control.

3. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

4. By using special lining import from Japan and high quality SiC heating elements with excellent acid and corrosion resistance, products are protected against chemical contamination at the best and long service life.

5. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

6. 7”color touch screen LCD man-machine English graphics interface, more intuitive and convenient operation.

7. With the exhaust device(an exhaust chimney in the top of the furnace), effectively remove volatiles generated during sintering

8. Easy to move casters, more convenient.

9. Low power consumable, exquisite structure and light weight, it is the ideal chamber furnace for labs.

Main Specifications:

| Model | M1500-30IT |

| Furnace structure | •1600 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

300*300*400mm |

| Max. temperature | 1500.C(<1 hour) |

| Working temperature | RT-1450.C(continuing) |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control and auto-tune function;

•30 programmable segments for precise control; •Built in protection for over-heated and broken thermal couple, and leakage; •Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation; •.Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes. |

| Heating element | High purity sic heating elements with excellent acid and corrosion resistance and long service life. |

| Heating rate | 0~20.C/min |

| Temperature accuracy | +/- 1.C |

| Thermocouple | S type |

| Working voltage | AC380V 50Hz |

| Max. Power | 6 Kw |

| Dimension | 640(W)*1530(H)*900(D)mm |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple, etc), lifetime support. |

| Certificate | CE, ISO |

Which kinds of industry can use this 1500.C Chamber Furnace?

College & Universities, New Material Research, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics, Ceramic, etc.

Applications:

Used in university laboratories, research institutes, and industrial & mining enterprise laboratories for sintering of metal ceramic materials, heat treatment of small steel parts, and quality testing.

In analytical chemistry industry, mainly used for sample treatment in water qualiy analysis, environmental analysis and other fields. It can also be used for oil and its analysis.

For heat working or treatment of small workpieces in cement and building materials industries.

Used in the pharmaceutical industry for drug inspection, pre-treatment of medical samples,etc.

In the coal mining industry for measuring moisture, ash, volatile matter, ash melting point analysis, ash composition analysis, and elemental analysis,etc.