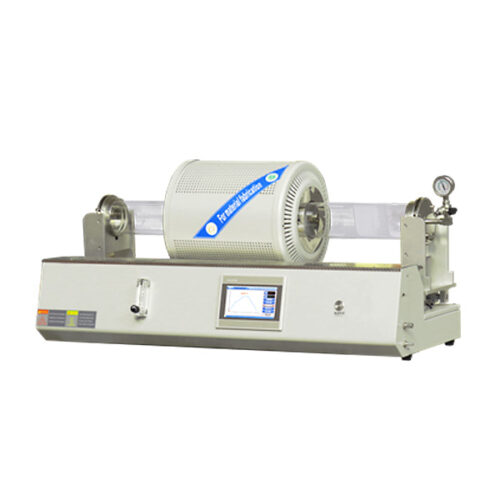

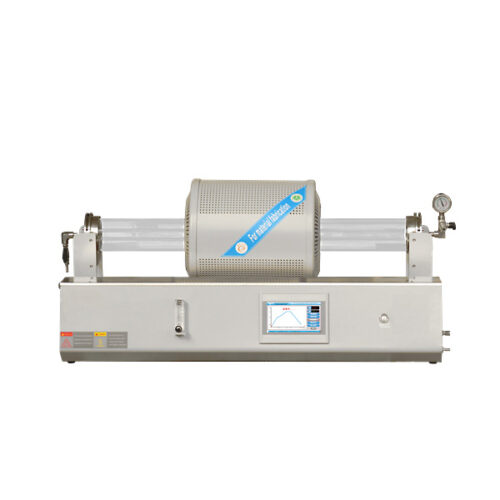

Continuing Operating Temperature 1400.C Atmosphere Furnace

Introduction:

The 1400.C atmosphere furnace adopts a metal shell sealing method, and the inner chamber of the furnace adopts a sandwich water-cooled structure design. The vacuum degree of the equipment in the cold state can reach below 50Pa.

It is also equipped with our independently developed touchscreen control system to enhance work efficiency. The furnace chamber can be customized according to the actual needs of users

.

Features of 1400.C Atmosphere Furnace:

- Adopting a double-layer water-cooled structure significantly reduces the surface temperature of the shell;

- Equipped with high-purity heating elements with superior acid resistance and corrosion resistance;

- The refractory insulation material manufactured using vacuum forming technology has low heat loss, effectively reducing the power consumption of the equipment;

- The integrated design of the inner chamber ensures the sealing of the system;

- The independent operating system with English-Chinese exchangeable graphical interface, 7-inch true color touchscreen input, intelligent human-machine dialogue mode, real-time heating power display, nonlinear style temperature correction; autonomous generation of experimental reports, unlimited export of experimental data.

Technical Details:

| Model | VA1200-20TI | VA1500-30TI | VA1700-30TI | |||

| Power Supply | AC220V 4KW | AC380V 6KW | AC380V 12KW | |||

| Max.Working temp | 1150.C | 1450.C | 1650.C | |||

| Continuing Working temp | 1100.C (Continuing) | 1400.C (Continuing) | 1600.C (Continuing) | |||

| Chamber Size | 200*200*300mm | 300*300*400mm | 300*300*400mm | |||

| System Vacuum | ≤100 Pa | |||||

| Recommend Heating Rate | ≤20.C/min | |||||

| Intelligent Control System | 1. Sintering Process Curve Setting: Dynamic display setting curve, the equipment sintering can pre-store multiple process curves, each process curve can be freely set.

2. Scheduling sintering is available, achieving unmanned sintering process according to set curves. 3. Real-time display of sintering power, voltage, and other information, recording sintering data, and exporting to achieve paperless recording. Remote control implementation, real-time observation of equipment status. 4. Temperature Calibration: Nonlinear correction is applied throughout the entire sintering process based on the temperature difference between the main control temperature and the sample temperature. |

|

||||

| Temperature Accuracy | +/- 1.C | |||||

| Heating Element |  |

|

||||

| Corrosion-resistant and acid-resistant alloy heating wire / high-purity silicon carbide rod /high-purity silicon molybdenum rod heating element | ||||||

| Service Support | 1-year warranty with lifelong support | |||||

Benefits of 1400.C Atmosphere Furnace:

Here are some benefits of a controlled atmosphere furnace:

- Minimized Oxidation: By controlling the atmosphere within the furnace, oxidation of sensitive materials can be minimized or eliminated, preserving their properties and reducing waste.

- Reduced Contamination: Controlling the atmosphere helps prevent contamination of materials by impurities present in the environment, resulting in purer end products.

- Versatility: Can be tailored to various atmospheres such as inert, reducing, or oxidizing, allowing for a wide range of applications including sintering, heat treatment, and annealing.

- Improved Safety: Offer feature advanced safety measures, such as gas monitoring and automatic shutdown systems, ensuring a safe working environment.

- Increased Efficiency: Optimized heating and cooling processes, along with precise control over parameters, lead to higher efficiency in material processing, reducing energy consumption and production time.

- Customization: Offer customizable settings and options to meet specific processing requirements, providing flexibility for various applications and industries.

Detail Applications:

Controlled atmosphere furnaces find application across various industries and research fields due to their ability to create specific environments for heat treatment and material processing. Some common applications include:

- Metallurgy: Controlled atmosphere furnaces are extensively used in metallurgical processes such as sintering, annealing, and tempering of metals and alloys to improve their mechanical properties, hardness, and resistance to corrosion.

- Ceramics: In the ceramics industry, these furnaces are employed for sintering ceramic materials, controlling the atmosphere to prevent oxidation and achieve desired properties like strength, density, and thermal conductivity.

- Powder Metallurgy: Controlled atmosphere furnaces play a crucial role in powder metallurgy processes, including powder compaction, sintering, and densification, to produce complex-shaped parts with superior mechanical properties.

- Semiconductor Manufacturing: They are used in semiconductor fabrication processes for annealing, diffusion, and oxidation of silicon wafers, ensuring precise control over doping levels and electrical properties.

- Aerospace and Automotive: These industries use controlled atmosphere furnaces for heat treatment of aerospace components, automotive parts, and engine components to enhance their strength, durability, and fatigue resistance.

- Research and Development: In laboratories and research institutions, controlled atmosphere furnaces are employed for studying material behavior under controlled environments, conducting experiments, and developing new materials with tailored properties.

- Electronics: They are used for soldering, brazing, and heat treatment of electronic components and circuit boards to ensure proper bonding, reliability, and performance in electronic devices.

- Energy Sector: In the energy sector, these furnaces are used for the fabrication of fuel cells, batteries, and renewable energy components, where controlled atmosphere conditions are crucial for optimizing material performance and efficiency.