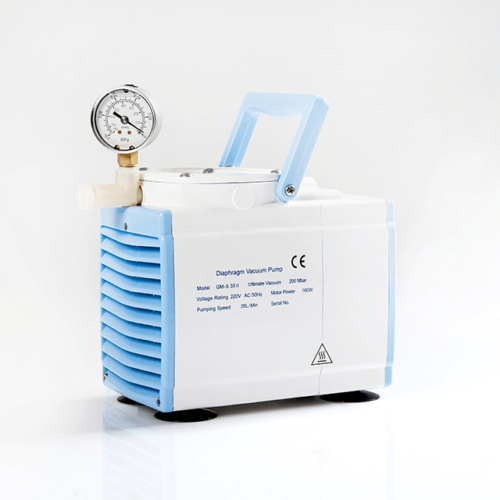

Single Stage Vacuum Pump

Introduction:

A single-stage vacuum pump is a type of pump commonly used in various applications that require the creation of a vacuum. It operates using a single stage of compression, it has one set of rotating vanes or impellers to create the vacuum.

It can be used alone or as a front stage pump for booster pumps and diffusion pumps. Suitable for electronic device manufacturing, vacuum drying, filtration, impregnation, coating, welding, smelting, and laboratory equipment.

Main Characteristic:

1. Adopting copper wire multi-layer winding motor, providing stable high-power output and long service life.

2. Large visible oil window to prevent oil shortage.

3. Integral cylinder structure, high precision, high ultimate vacuum.

4. 5-layer filtration effectively prevents oil smoke splashing and reduces noise.

Main Specification:

| Model | RS-1 | RS-1.5 | RS-2 | RS-3 | RS-4 | RS-6 | |||||||

| Voltage | 110V | 220V | 110V | 220V | 110V | 220V | 110V | 220V | 110V | 220V | 110V | 220V | |

| 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | 60Hz | 50Hz | ||

| Continuation Rate (CFM) | 3 | 2.5 | 4 | 3.5 | 5 | 4.5 | 7 | 6 | 9 | 8 | 12 | 10 | |

| Limiting pressure | PA | 2 | 2 | 2 | 2 | 2 | 2 | ||||||

| M | 15 | 15 | 15 | 15 | 15 | 15 | |||||||

| Speed(rpm) | 1720 | 1440 | 1720 | 1440 | 1720 | 1440 | 1720 | 1440 | 1720 | 1440 | 1720 | 1440 | |

| Power(HP) | 1/4 | 1/3 | 1/3 | 1/2 | 3/4 | 1 | |||||||

| Oil consumption(ML) | 220 | 225 | 250 | 250 | 300 | 450 | |||||||

| Overall dimensions(MM) | 260*110*240 | 275*115*240 | 290*120*240 | 310*125*255 | 360*135*270 | 430*142*280 | |||||||

Applications:

Single-stage vacuum pumps have a variety of applications across different industries. Here are some common applications where single-stage vacuum pumps are used:

1. Vacuum Filtration:

Single-stage vacuum pumps are often employed in laboratories for vacuum filtration processes. They create a vacuum to draw the liquid through a filter, separating solids from the liquid phase.

2. Vacuum Drying:

Single-stage vacuum pumps are used in vacuum drying processes to remove moisture from products or materials. They facilitate faster and more efficient drying by creating a vacuum environment that promotes the evaporation of moisture.

3. Degassing:

In industries such as electronics, pharmaceuticals, and food processing, single-stage vacuum pumps are used for degassing processes. They remove dissolved gases from liquids or materials to improve their quality or performance.

4. Laboratory Applications:

Single-stage vacuum pumps are utilized in various laboratory procedures, such as vacuum distillation, rotary evaporation, vacuum ovens, and freeze drying. They enable researchers to create and control a vacuum environment for experimental purposes.

5. Analytical Instruments:

Single-stage vacuum pumps are utilized in analytical instruments like mass spectrometers and electron microscopes. They create a vacuum environment necessary for accurate measurements and sample analysis.

These are just a few examples of the diverse range of applications where single-stage vacuum pumps are employed. The specific choice of vacuum pump depends on the requirements of the application, including the desired vacuum level, pumping speed, and any specific environmental or operational considerations.

Benefits

Single-stage vacuum pumps offer several benefits that make them valuable for various applications. Here are some key benefits of using a single-stage vacuum pump:

1. Cost-effective:

Single-stage vacuum pumps are generally more affordable compared to high-vacuum pumps or multi-stage vacuum systems. They provide a cost-effective solution for applications that require moderate vacuum levels without the need for ultra-high vacuum capabilities.

2. Versatility:

Single-stage vacuum pumps are versatile and suitable for a wide range of applications. They can be used in laboratories, industrial processes, HVAC systems, packaging, and more. Their flexibility allows them to be employed in different industries and settings.

3. Simplicity:

Single-stage vacuum pumps have a relatively simple design with fewer moving parts compared to complex high-vacuum systems. This simplicity makes them easier to operate and maintain, reducing the chances of breakdowns or maintenance issues.

4. Compact and Portable:

Single-stage vacuum pumps are often compact and lightweight, making them easier to transport and install. This portability allows for flexibility in different work environments and makes them suitable for applications where space is limited.

5. Moderate Vacuum Levels:

Single-stage vacuum pumps are capable of achieving moderate vacuum levels, typically in the range of a few millibars to several hundred millibars. These levels are sufficient for many common applications, including vacuum filtration, degassing, and vacuum drying.

6. Reliability:

Single-stage vacuum pumps are known for their reliability and durability. With proper maintenance and care, they can provide consistent performance over an extended period.

7. Lower Power Consumption:

Single-stage vacuum pumps generally consume less power compared to high-vacuum pumps, reducing energy costs in operation.

8. Ease of Operation:

Single-stage vacuum pumps are typically straightforward to operate, often requiring minimal training or expertise. They often have simple control mechanisms and user-friendly interfaces.

9. Compatibility:

Single-stage vacuum pumps can be compatible with a range of gases and can handle various gas compositions without significant limitations.

While single-stage vacuum pumps have numerous advantages, it’s important to consider the specific requirements of your application and ensure that the chosen pump meets those requirements effectively.

FAQ

Q1: What is the difference between a single-stage vacuum pump and a multi-stage vacuum pump?

A1: The main difference lies in the number of stages of compression. A single-stage vacuum pump has only one set of rotating vanes or impellers to create the vacuum, while a multi-stage vacuum pump has multiple sets of vanes or impellers, allowing for more stages of compression and the ability to achieve higher vacuum levels.

Q2: Can a single-stage vacuum pump achieve high vacuum levels?

A2: Single-stage vacuum pumps are typically designed to achieve moderate vacuum levels rather than high vacuum levels. They are suitable for applications that require vacuum levels in the range of a few millibars to several hundred millibars. If you need to achieve extremely high vacuum levels, a multi-stage or high-vacuum pump would be more appropriate.

Q3: Do single-stage vacuum pumps require oil?

A3: Yes, it requires oil. It is oil vacuum pump.