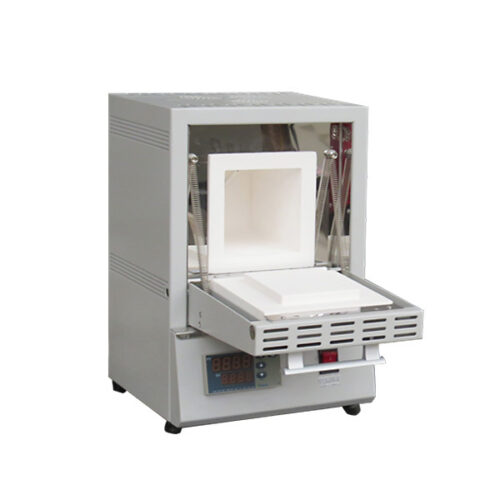

1200.C Mini Tube Furnace

Introduction:

Small size, high performance, very popular in labs. It has a generous, 7” colored graphic touch panel with which the furnace can be controlled and complex heating process can also be programmed. Clear heating curves ; can store and preset temperature curves to avoid the trouble caused by repeated settings of different experimental processes. Satisfy the vacuum sintering of the vast majority of materials, the sintering of the protective atmosphere and all kinds of CVD experiments, etc.

The first-class workmanship using high-quality materials, combined with ease of operation, make the mini tube furnace all-rounders in research and the laboratory. Especially suitable for laboratory pyrolysis experiments, etc.

Main Features:

1. High purity quartz tube as furnace tube, Max. Temperature 1200C, working temperature Rt –1100C.

2. 30 segments programmable and auto control.

3. 7”Color Touch screen LCD man-machine English interface, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

4. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

5. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

6.By using special lining import from Japan and high quality resistance wire, protected against chemical contamination at the best and longer service life.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50C, safety for the operator.

8.Ring heating, open structure, convenient observation for operator, able to meet rapid sintering of small sample.

9.Unique flange has a multi-function test holes, insert the corresponding electrode to test tube temperature or atmosphere environment.

10. Can add modules to contol and download data remotely(optional).

11. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for material research labs, also used in factory for small production.

Technical Parameters of Mini Tube Furnace:

| Model | O1200-50IT |

| Product Name | 1200.C Open Mini Tube Furnace |

| Chamber Model | Open |

| Chamber Material | Imported high quality alumina fiber refraction insulation |

| Heating Element | High quality resistance wire |

| Max.temperature | 1200℃ |

| Working Temperature | ≤1100℃ |

| Heating Rate | ≤20℃/min(advice:10℃/min) |

| Heating Zone | Single |

| Length of Heating Zone | 200mm |

| Constant

Temperature Zone |

120mm |

| Tube Material | High purity quartz |

| Tube Diameter | OD50mm(ID45mm)

Optional: OD25mm(ID20mm) |

| Tube Length | 600mm |

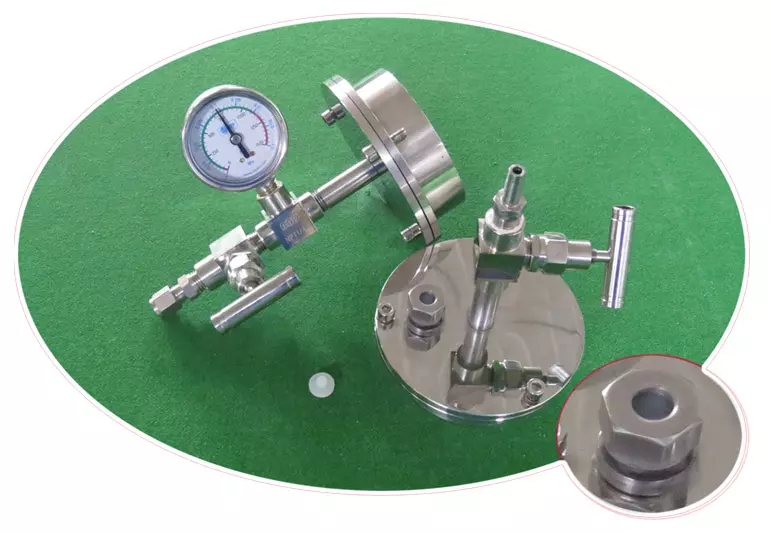

| Sealing Mode | Vacuum Flange |

| Control Mode | 7 inch Touch Screen, Intelligent PID Control |

| Operating Interface | English Graphical Interface |

| Temperature Accuracy | +/- 1.C |

| Presetting Curve | 15 Presetting Curve, 30 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Protection |

| Thermocouple | K Type |

| Certification | CE, ISO |

| Working Voltage | AC 110-240V 50/60 Hz |

| Power | 1.2KW |

| Dimension | 380(L) * 350(W) * 450(H)mm |

| Net Weight | 23kgs |

| Standard Accessories | Quartz Tube, Vacuum Flange, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

Which kinds of industry can use this Mini Tube Furnace?

College & Universities, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics, Ceramic, etc.

Detail Applications:

Mini tube furnaces have various applications across different industries and research fields due to their compact size and versatility. Some common applications include:

Material Synthesis and Processing

Mini tube furnaces are commonly used for the synthesis and processing of materials such as nanoparticles, thin films, ceramics, and composites. They provide controlled heating environments suitable for chemical reactions, crystallization, and phase transformations.

Annealing and Sintering

These furnaces are used for annealing processes, which involve heating materials to high temperatures and then allowing them to cool slowly to relieve internal stresses and increase their ductility. They are also used for sintering processes, which involve compacting and heating powdered materials to form solid objects.

Thermal Analysis

Mini tube furnaces are utilized in thermal analysis techniques such as thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) to study the thermal properties of materials, including their decomposition, phase transitions, and thermal stability.

Crystal Growth

In materials science and semiconductor industries, mini tube furnaces are employed for crystal growth processes, including the growth of single crystals and thin films. These processes are crucial for manufacturing semiconductor devices, LEDs, and photovoltaic cells.

Carbonization and Pyrolysis

Mini tube furnaces are used for carbonization and pyrolysis processes, which involve heating organic materials in an inert atmosphere to convert them into carbonaceous substances or to break down complex molecules into simpler ones.

Catalysis Studies

In chemical research, mini tube furnaces are used to study catalytic reactions by providing precise control over temperature and atmosphere conditions. This helps researchers understand the kinetics and mechanisms of catalytic processes.

Powder Metallurgy

Mini tube furnaces play a role in powder metallurgy processes, including the production of metal powders, compaction of powders into shapes, and sintering of powdered metals to form dense, solid components.

Heat Treatment

These furnaces are utilized for heat treatment processes such as tempering, hardening, and normalizing of metals to modify their mechanical properties, including hardness, strength, and toughness.

Research and Development

Mini tube furnaces are essential tools in research and development laboratories across various disciplines, including materials science, chemistry, physics, and engineering. They enable researchers to explore new materials, processes, and applications.

Overall, mini tube furnaces offer precise temperature control, uniform heating, and a controlled atmosphere, making them indispensable in a wide range of industrial and research applications.

Advantages and Benefits:

Mini tube furnaces offer several benefits due to their compact size, versatility, and precise temperature control. Some of the key benefits include:

Compact Size

Mini tube furnaces are small and portable, making them suitable for use in limited laboratory spaces or in field applications where space is constrained. Their compact design also allows for easy integration into existing experimental setups.

Versatility

These furnaces can be used for a wide range of applications, including material synthesis, annealing, sintering, thermal analysis, crystal growth, catalysis studies, and more. Their versatility makes them valuable tools in various industries and research fields.

Precise Temperature Control

Mini tube furnaces offer precise temperature control, allowing users to heat samples to specific temperatures with high accuracy. This precision is crucial for reproducible experiments and ensures reliable results.

Uniform Heating

Mini tube furnaces provide uniform heating throughout the heating zone, resulting in consistent treatment of samples. This uniformity is essential for achieving homogeneous material properties and reliable experimental outcomes.

Controlled Atmosphere

Mini tube furnaces offer the ability to control the atmosphere within the heating chamber, allowing users to carry out experiments under specific gas environments (e.g., inert, oxidizing, reducing). This feature is particularly useful for studies involving sensitive materials or catalytic processes.

Ease of Operation

Mini tube furnaces are designed for ease of operation, with user-friendly interfaces and intuitive controls. This simplifies setup and operation, allowing researchers to focus on their experiments rather than technical details.

Energy Efficiency

Despite their small size, mini tube furnaces are energy-efficient, consuming relatively low amounts of power compared to larger industrial furnaces. This can lead to cost savings on energy bills and make them environmentally friendly options.

Safety Features

Mini tube furnaces are equipped with safety features such as overtemperature protection, thermal insulation, and automatic shutdown mechanisms. These features help prevent accidents and protect both the user and the equipment.

Affordability

Compared to larger industrial furnaces, mini tube furnaces are more affordable, making them accessible to a wider range of users, including small laboratories, educational institutions, and startups.

Overall, mini tube furnaces offer a combination of compactness, versatility, precision, and safety, making them valuable tools for a variety of heating and thermal processing applications in both research and industrial settings.

Click to see more content:

Understanding Tube Furnace Temperatures: Medium vs. High-Temperature Applications