1200.C Mini Box Furnace

Introduction:

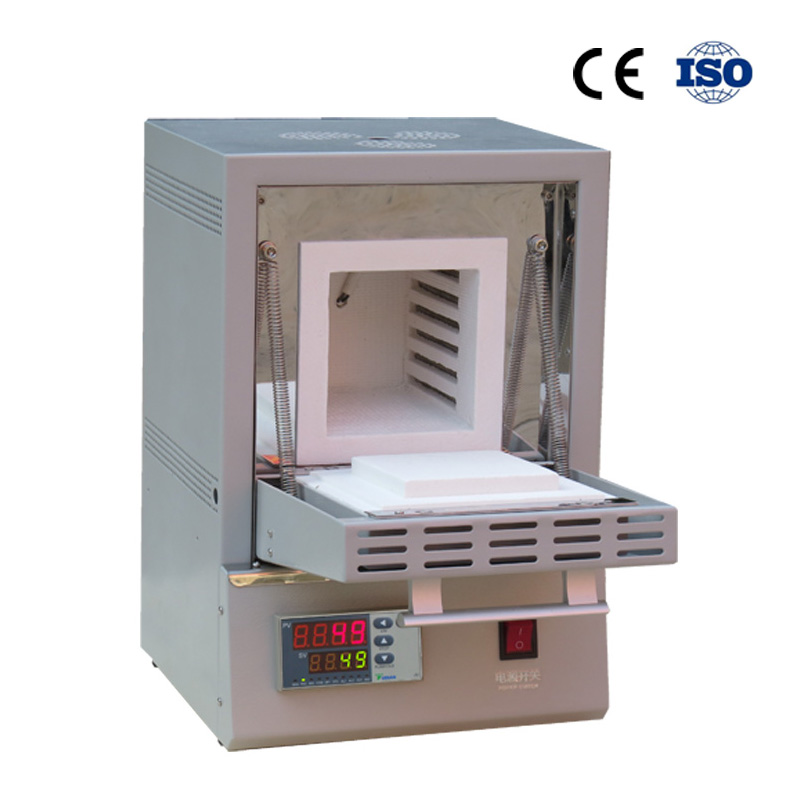

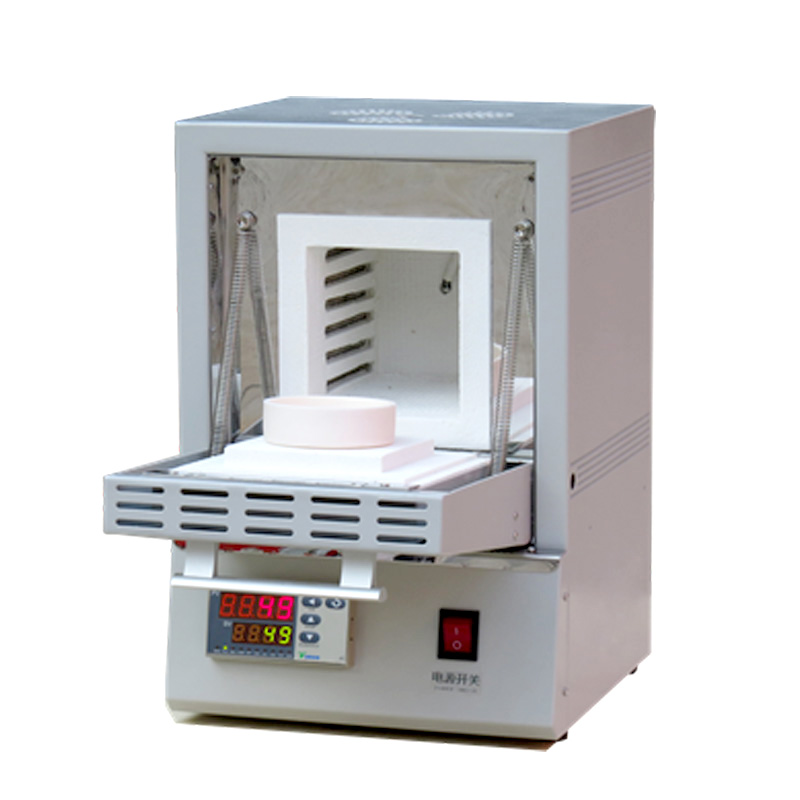

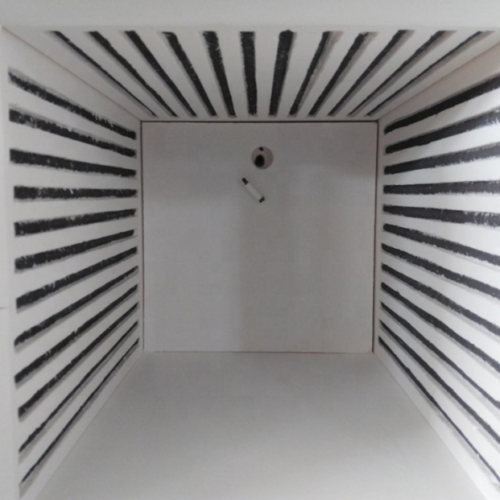

The mini box furnace has a scientific and reasonable drop-down door structure, and the materials can be taken out and placed directly on the furnace door to avoid burns on the workbench. And has an exquisite shape and a small volume. Widely used in universities, scientific research institutes and laboratories.

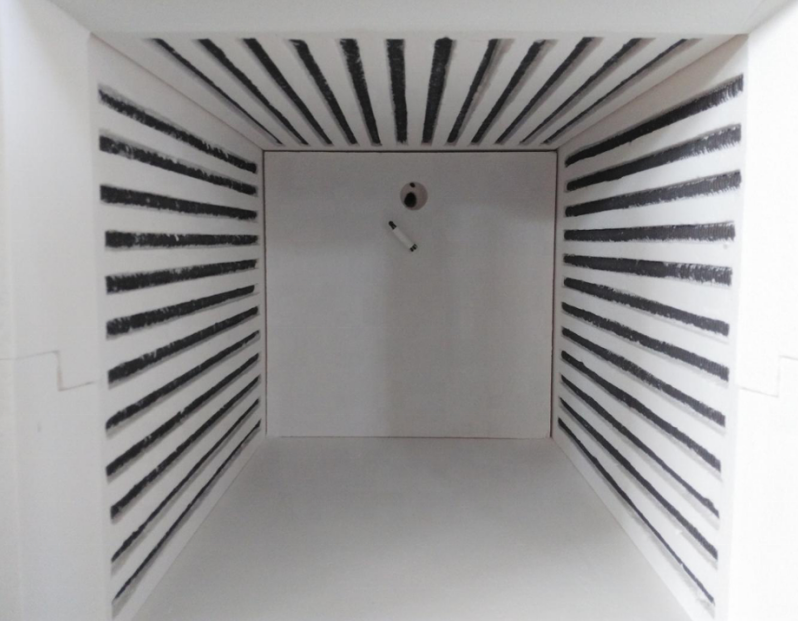

In addition, it uses a molybdenum-iron-chromium-aluminum alloy heating wire coated with an antioxidant material. Slightly exposed vacuum forming wire layout method, evenly distributed heating on three sides, effectively enhances the uniformity of the temperature field in the furnace, and greatly improves the high-temperature service life of the heating element.

Main Features:

1.Max. Temperature 1200.C, working temperature RT — 1100C.

2. 30 segments programmable and auto control.

3. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

4 By using special lining import from Japan and top quality resistance wire, protected against chemical contamination at the best and longer service life.

5.Double layers steel casing with fan cooling, to ensure the surface of furnace below 50C, safety for the operator.

6. Scientific and reasonable hinged door(Drop-down Door) that can be used as additional loading and unloading space.

7. Vent hole carefully designed in the top is the perfect solution to the waste gas during material sintering.

8. Low power consumable, exquisite structure and light weight, it is the ideal box furnace for labs and production in factory.

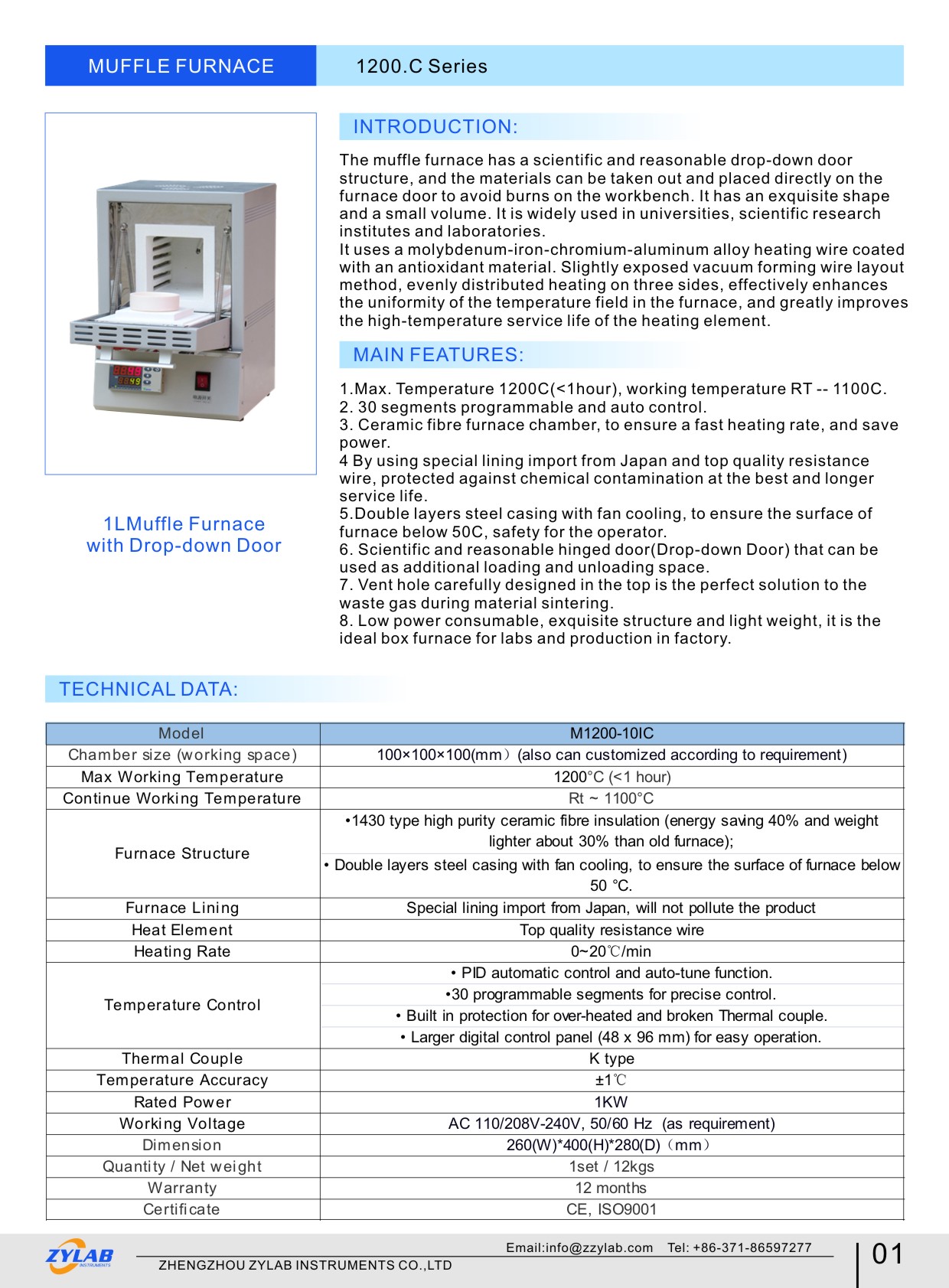

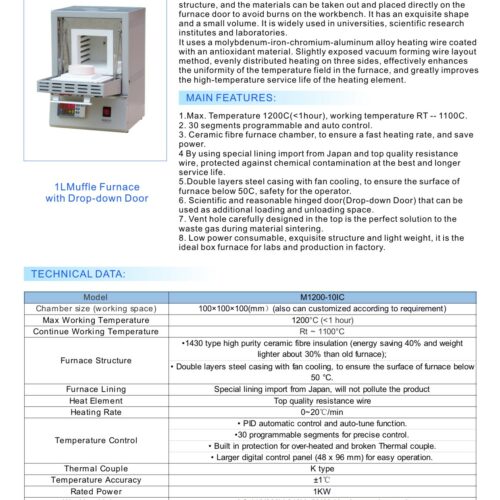

Main Specifications:

| Model | M1200-10IC |

| Chamber size

(working space) |

100×100×100(mm) |

| Max Working Temperature | 1200.C (<1 hours) |

| Continue

Working Temperature |

Rt ~ 1100.C |

| Furnace Structure | •1430 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Furnace Lining | Special lining import from Japan, will not pollute the product |

| Heat Element | Top quality resistance wire |

| Heating Rate | 0~20.C/min |

| Temperature Control | • PID automatic control and auto-tune function. •30 programmable segments for precise control. • Built in protection for over-heated and broken Thermal couple. • Larger digital control panel (48 x 96 mm) for easy operation. |

| Thermal Couple | K type |

| Temperature Accuracy | ±1.C |

| Rated Power | 1KW |

| Working Voltage | AC 110/208V-240V, 50/60 Hz

(as requirement) |

| Dimension | 260(W)*400(H)*280(D)(mm) |

| Quantity / Net weight | 1set / 12kgs |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. |

| Certificate | CE, ISO9001 |

Which kinds of industry can use this Mini Box Furnace?

Universities, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics,etc.

Applications:

Used in university laboratories, research institutes, and industrial and mining enterprise laboratories for sintering of metal ceramic materials, heat treatment of small steel parts, and quality testing.

For heat working or treatment of small workpieces in cement and building materials industries.

In the pharmaceutical industry for drug inspection, pre-treatment of medical samples,etc.

In analytical chemistry industry, mainly used for sample treatment in water qualiy analysis, environmental analysis and other fields. It can also be used for oil and its analysis.

Used in the coal mining industry for measuring moisture, ash, volatile matter, ash melting point analysis, ash composition analysis, and elemental analysis. It can also be used as a universal ashing furnace.