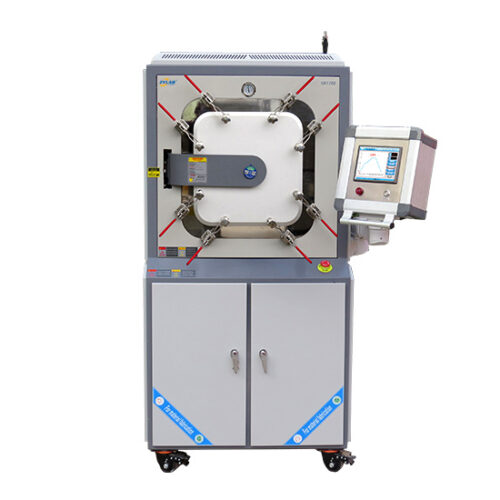

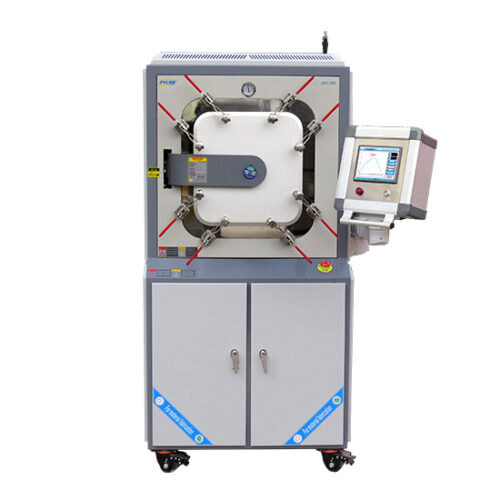

Vacuum Furnace

A vacuum furnace is a specialized piece of equipment used in materials processing and heat treatment, particularly in industries like aerospace, automotive, electronics, and metallurgy. It operates under low-pressure or vacuum conditions to create controlled environments for various thermal processes. Here are key features and applications of vacuum furnaces:

Key Features:

- Vacuum Environment:

- A vacuum furnace operates in a controlled low-pressure or vacuum environment, minimizing the presence of oxygen and other reactive gases.

- Uniform Heating:

- Provides uniform heating of materials, ensuring consistent and controlled thermal processing.

- Preventing Oxidation:

- Eliminates the risk of oxidation and contamination of materials, making it suitable for processes requiring clean and controlled atmospheres.

- Heat Treatment:

- Commonly used for heat treatment processes such as annealing, brazing, sintering, and hardening of metals and alloys.

- Brazing and Soldering:

- Ideal for joining materials through brazing and soldering, ensuring strong and reliable bonds without the need for flux.

- Debinding and Sintering:

- Used in powder metallurgy for debinding and sintering processes, allowing the production of complex-shaped components with high precision.

- Thermal Processing of Aerospace Components:

- Applied in the aerospace industry for treating critical components like turbine blades to enhance their mechanical properties.

- Research and Development:

- Utilized in research and development laboratories for studying material behavior under controlled thermal conditions.

- Clean Atmosphere Processing:

- Suitable for processes that require a clean and controlled atmosphere, such as the production of electronic components and devices.

100-1200.C

800-1700.C

Bottom Loading Furnace

2200°C Vacuum Tungsten Sintering Furnace | Precision Heat Treatment Equipment

CVD Furnace System