800-1700.C

800-1700.C

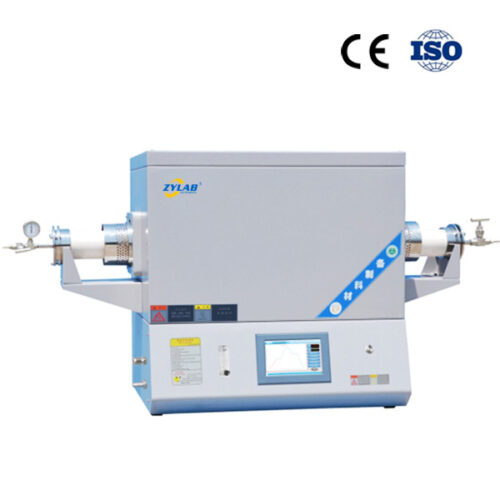

CVD Furnace System

Showing 13–24 of 117 results

800-1700.C

800-1700.C

CVD Furnace System

Controlled Atmosphere Furnaces

Advanced Clean Box Hydrogen Reduction Furnace for Metallurgy and Material Science

We offer a variety of tube furnaces, including mini tube furnaces, vacuum tube furnaces, sliding tube furnaces, and CVD tube furnaces, to meet the different needs for annealing, sintering, heat treatment, and chemical reactions of many university projects, research institutions, and companies.

A tube furnace is a type of furnace used for heating materials in a tube-shaped chamber. It is commonly used in laboratory and industrial processes for thermal treatment, such as calcination, sintering, and annealing, where precise temperature control is required.

Our tube furnaces can reach up to 1200°C or 1500°C, we also offer high-temperature furnaces that go up to 1700°C.

Sure, our tube furnaces feature programmable controllers for multi-step heating, holding, and cooling processes via an intuitive and easy-to-operate touch screen, with the ability to pre-setting sintering curves.

The heating rate range can be from 1°C/hour to 20°C/min.

Our tube furnaces are designed for high temperature uniformity, with differences usually within ±5°C, and temperature control accuracy within ±1°C.

Tube furnaces come in various sizes depending on the application, from small laboratory units with tube diameters around 25 mm to 100 mm to large industrial units with diameters exceeding 300 mm.

Split tube furnaces have a design that allows the furnace to open along the middle, making it easier to insert and remove the tube. This is particularly useful for experiments that require frequent loading and unloading of samples.

Temperature is controlled through intelligent controllers, offering precise temperature settings and automated ramping profiles.

ZYLAB tube furnaces use high-quality vacuum formed ceramic fiber insulation to minimize heat loss and improve energy efficiency.

Yes, all ZYLAB tube furnaces come with stainless steel flange, can be used under vacuum or inert gas(controlled atmosphere) environments.

For more information on tube furnaces, please read our article here.

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!

Notifications

Welcome to ZYLAB.

Ask us anyting :)