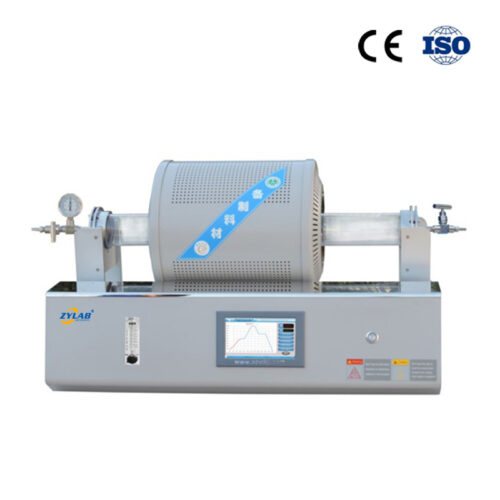

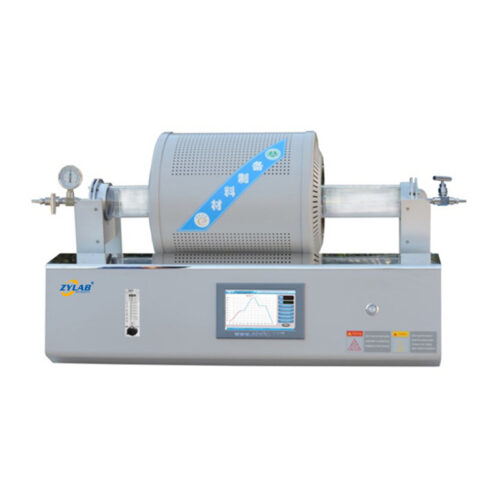

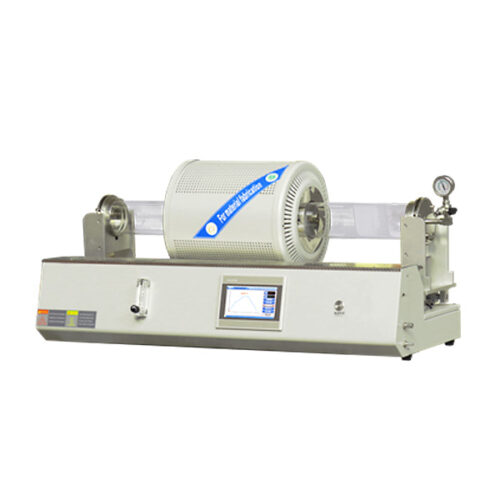

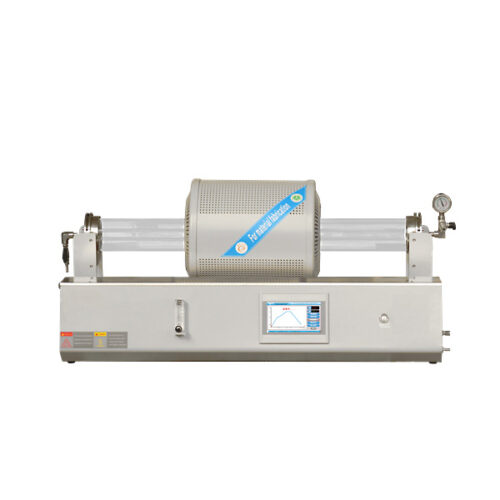

RTP Furnace

RTP furnace refers to a Rapid Thermal Processing Furnace, a high-temperature furnace specifically designed for rapid heating and cooling. It is widely used in semiconductor manufacturing and materials research.

Features

Rapid Heating and Cooling: Heating rate up to 140°C/min; cooling rate from 1200°C to 300°C can reach 200~50°C/min.

High Temperature Uniformity: Ensures uniform temperature distribution in the heating zone, minimizing thermal gradients during heat treatment.

Atmosphere Control: Operable in various atmospheric environments, such as vacuum, inert gas, or oxidizing atmospheres.

Precise Temperature Control: Equipped with a high-precision temperature control system.

Typical Applications of RTP Furnace

Semiconductor Manufacturing:

- Rapid Thermal Annealing (RTA): Used for surface recovery and dopant activation of silicon wafers or other substrates.

- Post-deposition heat treatment for thin films.

Materials Science Research:

- Thermal treatment of two-dimensional materials (e.g., graphene, transition metal sulfides).

- Annealing or phase transformation processes in nanomaterial preparation.

Photovoltaic Industry:

- Process optimization for silicon-based solar cells.

Other High-Temperature Short-Time Processes:

- Surface modification or rapid sintering of metals, ceramics, and other composite materials.

At ZYLAB, we offer top-tier thermal processing equipment designed for precision and reliability, along with premium materials for material science and powder metallurgy. Browse our RTP furnaces now and request a quote for more information.

100-1200.C

100-1200.C