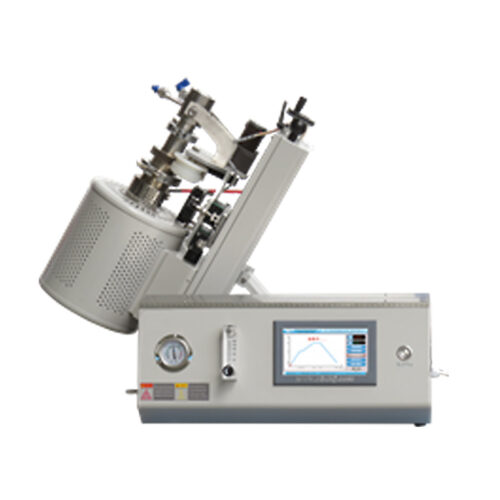

Rotary Furnace

A Rotary Furnace is an advanced high-temperature furnace designed to rotate around its axis during operation. This unique design enables efficient processing of various materials through heating, drying, chemical reactions, and sintering. Ideal for high-temperature applications, the rotary furnace ensures uniform heating, which is crucial for achieving precise material transformation.

Main Applications:

Rotary furnaces are versatile and widely used across multiple industries for processes such as:

- Laboratory Calcination: Ideal for high-temperature chemical processes and material transformations.

- Drying: Efficient drying of powdered or granular materials.

- Heat Treatment & Carbonization: Suitable for heat treatment of materials requiring precise thermal control.

- Sintering and Reactions: Effective for conducting high-temperature reactions, including sintering and chemical processes.

Materials Processed:

Our rotary furnaces are capable of handling a variety of materials, including but not limited to:

- Lithium-ion Battery Components: Such as iron aluminum phosphate, lithium manganese oxide, lithium cobalt oxide, ternary materials, and graphite anodes.

- Rare Earth Materials: Processing critical materials for industries like electronics and energy.

- Chemical Catalytic Materials: Used in refining and chemical production.

- Magnetic Materials: For the production of high-performance magnets.

- Powder Metallurgy Materials: Processing powders for sintering and metalworking applications.

- Non-ferrous Metals: Ideal for non-ferrous metal processing and treatment.

- Non-metallic Mineral Materials: Including kaolin and other minerals for various industrial applications.

Customization Options:

We offer customizable atmospheric conditions during the sintering process, ensuring the rotary furnace meets specific requirements for each material and application. Users can tailor the atmosphere to suit processes such as reduction, oxidation, or inert gas environments.

ZYLAB expert team is always ready to assist you in finding the best solutions for optimal performance. Contact us today to discuss your requirements!

100-1200.C

100-1200.C

100-1200.C