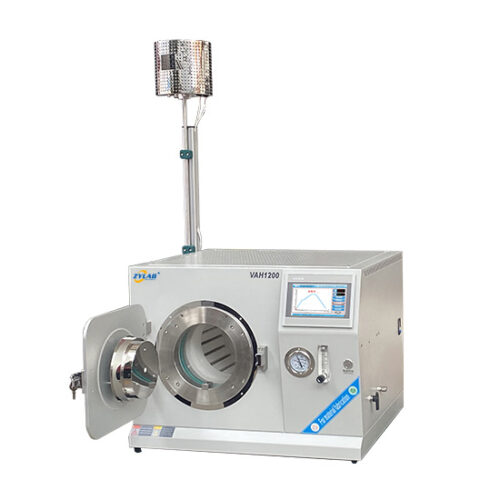

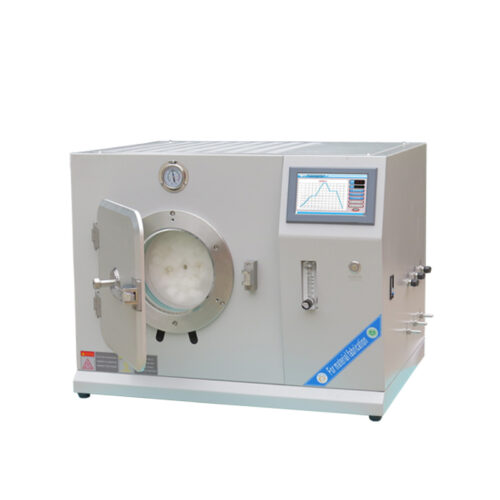

Hydrogen Reduction Furnace

ZYLAB Hydrogen Reduction Furnace is fully-automated compact specialized equipment developed for higher education institutions, research institutes, and industrial enterprises. It is designed for sintering, melting, and analyzing metals, non-metals, and other compound materials under atmospheric and vacuum conditions.

The Furnace consists of the following components:

Sintering System

Electrical Control System

Inlet and Outlet Gas Systems

Vacuum System

Ignition System

Advantage of ZYLAB Hydrogen Reduction Furnace

1. Unique ignition device, has the capability to ignite and treat combustible tail gases, with a dual ignition protection system in place to ensure the complete combustion of discharged gases.

2. Suitable for both low vacuum and atmosphere controlled sintering.

3. Incorporates safety features such as pressure monitoring within the furnace tube, providing functions like gas cutoff and temperature reduction.

4. Large 7-inch true-color touch screen controller allows for intelligent fully-automated control.

Key applications

- Powder Metallurgy

- Materical Science

- Additive Manufacturing (3D Printing)

- Battery and Energy Storage R&D

Request a Quote

At ZYLAB, we offer top-tier thermal processing equipment designed for precision and reliability, along with premium materials for material science and powder metallurgy. Browse our Hydrogen Reduction Furnaces now and request a quote for more information.

Controlled Atmosphere Furnaces

Controlled Atmosphere Furnaces

Controlled Atmosphere Furnaces

100-1200.C