100-1200.C

Showing 25–36 of 38 results

100-1200.C

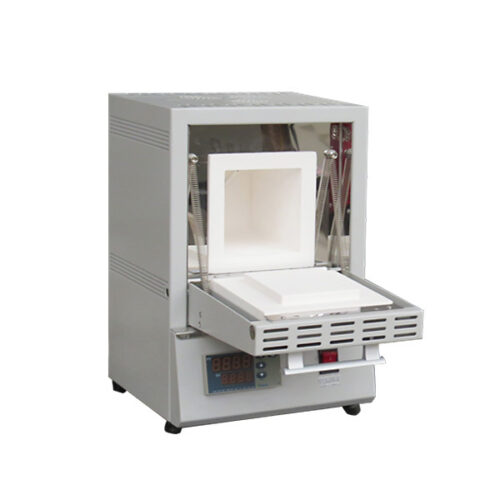

A chamber furnace is an industrial heating device with an insulated chamber used to heat materials to high temperatures for processes like sintering, annealing, or heat treatment. It offers precise temperature control, uniform heat distribution, and is commonly used for metals, ceramics, and polymers in various industries.

A chamber furnace heats materials in a sealed, insulated chamber using heating elements. It controls temperature precisely through a digital system, ensuring uniform heat distribution for processes like sintering or annealing. Safety features protect against over-temperature and other risks.

Chamber furnaces can be used to process a wide range of materials, including metals, ceramics, glass, polymers, and other materials requiring heat treatment, sintering, or thermal analysis, etc.

Main applications include metal annealing, ceramic sintering, plastic heat treatment, glass annealing, electronic component baking, and material testing.

Our chamber furnaces can reach up to 1200°C or 1500°C, we also offer high-temperature chamber furnaces that go up to 1700°C.

Many of our chamber furnaces can be equipped with atmosphere control systems, such as oxygen, nitrogen, hydrogen, etc., for specific heat treatment processes.

Some of chamber furnaces are designed for operation in vacuum environments, suitable for processes requiring low or no oxygen.

Regular checks of the heating elements, temperature control system, and door seals. The furnace chamber should also be kept clean.

Yes, chamber furnaces are commonly used for ceramic sintering, especially for small batch experiments or production needs.

Our chamber furnaces are designed to minimize energy consumption by using advanced insulation materials and intelligent control systems to maximize energy efficiency.

Through high-precision temperature sensors, well-arranged heating elements, and air circulation systems, chamber furnaces maintain good temperature uniformity, with differences normally within ±5°C..

Yes, chamber furnaces are suitable for chemical reactions that require high temperatures and specific atmospheres, commonly used for material synthesis and calcination processes.

When selecting a chamber furnace, consider factors such as the type of material being processed, temperature requirements, atmosphere needs, chamber size, control system, and usage frequency.

The choice depends on the sample size and batch requirements. We offer chamber furnaces with varying chamber capacities, from 1L to 640L.

Our chamber furnaces utilize three types of high-performance heating elements:

Each type is selected for its durability and efficiency, ensuring reliable and consistent heating performance.

Sure, our chamber furnaces feature an 7” intelligent touch screen programmable controllers for multi-step heating, holding, and cooling processes.

The heating rate range from 1°C to 20°C per minute.

Temperature is controlled through intelligent touch screen controllers, offering precise temperature settings and automated ramping profiles.

Our chamber furnaces use high-quality vacuum formed ceramic fiber insulation to minimize heat loss and improve energy efficiency.

Our chamber furnaces are equipped with over-temperature protection, power failure protection, thermocouple disconnection alerts, and other safety mechanisms to ensure safe operation.

The heating time depends on the furnace model, size, and temperature setting. Typically, our chamber furnaces can reach their maximum temperature within a few hours to several dozen hours.

Yes, our chamber furnaces feature user-friendly controls, intuitive interfaces, and clear instructions, making them easy to operate even for those with limited experience.

Our engineers can assist you in selecting the best chamber furnace based on your specific requirements, including material type, temperature range, and processing needs.

Notifications

Welcome to ZYLAB.

Ask us anyting :)