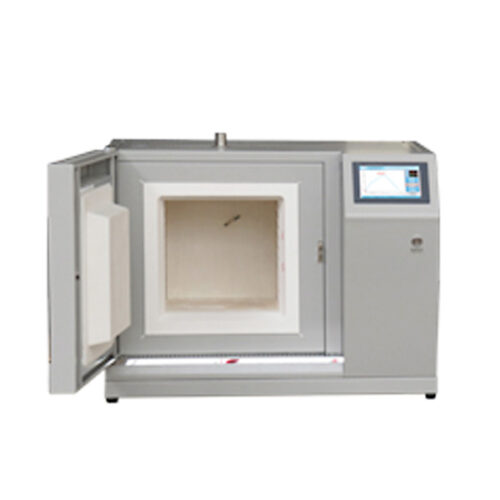

Box Furnaces

Box Furnaces are versatile thermal processing equipment designed for laboratory and industrial applications. They provide controlled high-temperature environments ideal for processes such as sintering, annealing, drying, and heat treatment. These furnaces feature a spacious chamber to accommodate larger samples or multiple items simultaneously.

ZYLAB Box Furnaces are extensively used in scientific research, quality control, and industrial production. They are known for their excellent temperature uniformity and stability, ensuring accurate and reliable results. With advanced programmable temperature controllers, robust safety features, and high-performance insulation materials, these furnaces create optimal conditions for thermal processing and material analysis.

ZYLAB offers a comprehensive range of box furnaces tailored to diverse thermal needs. Here, you can explore details on different models, chamber sizes, and temperature ranges, along with their unique features and capabilities. Whether you require a compact benchtop furnace or a larger unit for industrial-scale applications, ZYLAB provides options to suit your specific requirements.

The ZYLAB expert team is always available to help you find the best solution for your application needs. If you have specific requirements, contact us today!

100-1200.C

100-1200.C

100-1200.C

500-1500.C

100-1200.C

100-1200.C