Powder Metallurgy

Welcome to our specialized section on Powder Metallurgy, a cutting-edge manufacturing process that transforms powdered metals into strong, durable components.

Powder Metallurgy process typically includes the following steps

Powder Production: Metal powders are created through various methods like atomization, reduction, electrolytic processes, or mechanical alloying.

Mixing: The metal powders are mixed with other elements or binders to achieve the desired material properties.

Compaction: The mixed powders are compressed into a desired shape using a die under high pressure. This step forms a “green” compact that holds its shape but is not yet fully solidified.

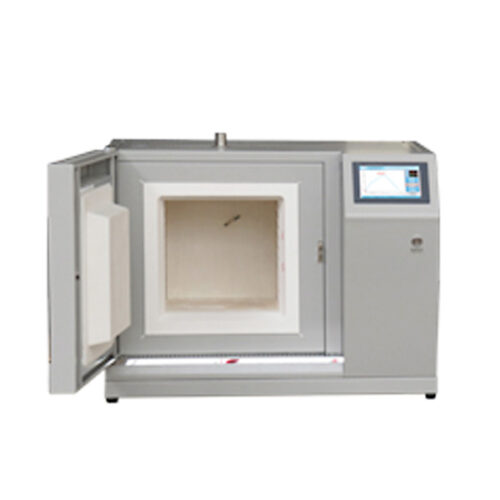

Sintering: The green compact is heated in a controlled atmosphere furnace to a temperature below the melting point of the main constituent. This process bonds the powder particles together, resulting in a solid and strong part.

Secondary Operations: Depending on the application, further processes such as machining, surface treatment, or heat treatment may be required to achieve the final product specifications.

Applications of Powder Metallurgy

- Automotive Industry: Manufacturing of gears, bearings, bushings, and other components with complex shapes and tight tolerances.

- Aerospace: Production of lightweight and high-strength components, such as turbine blades and structural parts.

- Medical: Creation of biocompatible implants, such as dental implants and orthopedic devices.

- Tooling: Production of cutting tools, dies, and molds with enhanced wear resistance and toughness.

- Electronics: Manufacturing of magnetic components, electrical contacts, and conductive materials.

Powder metallurgy is known for its ability to produce parts with complex geometries, high material utilization, and minimal waste. It is also advantageous for creating materials with unique properties, such as composites and metal matrix materials.