Material Analysis

Material analysis is a crucial aspect of understanding the properties, composition, and structure of materials. It involves various techniques and methods to examine and characterize materials at the atomic, molecular, and macroscopic levels.

Common techniques used in material analysis:

Thermal Analysis:

Differential Scanning Calorimetry (DSC):

Measures heat changes in a material in response to temperature changes.

Useful for studying phase transitions, purity, and reaction kinetics.

Thermogravimetric Analysis (TGA):

Measures changes in weight as a function of temperature.

Useful for analyzing thermal stability and composition changes.

Mechanical Testing:

Tensile Testing:

Measures the mechanical properties of materials, including strength, elasticity, and ductility.

Applies tension to a material until it breaks.

Hardness Testing:

Measures a material’s resistance to deformation, often used for quality control.

Common methods include Rockwell, Vickers, and Brinell hardness tests.

Chemical Analysis:

X-ray Diffraction (XRD):

Determines the crystal structure of a material by analyzing the diffraction pattern of X-rays.

Used for phase identification and crystallography.

Energy-Dispersive X-ray Spectroscopy (EDS):

Identifies the elemental composition of a sample using X-ray fluorescence.

Often coupled with scanning electron microscopy (SEM).

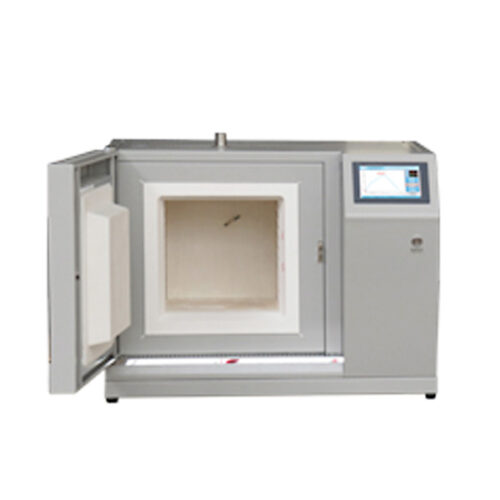

Battery R&D

100-1200.C

100-1200.C

100-1200.C

100-1200.C

500-1500.C