Magnetic Material Preparation Solution

Magnetic material preparation is a critical aspect of various applications, including electronics, information storage, medical devices, and energy conversion.

Magnetic Material Preparation Techniques:

Powder Metallurgy:

Raw Material Selection: Choose suitable magnetic elements or compounds.

Powder Synthesis: Prepare fine magnetic powders through methods like mechanical milling or chemical precipitation.

Compaction: Press the magnetic powders into the desired shape.

Sintering: Heat the compacted powders to high temperatures, promoting grain growth and enhancing magnetic properties.

Chemical Synthesis:

Solution Methods: Use chemical processes like co-precipitation, sol-gel, or hydrothermal synthesis to create magnetic nanoparticles.

Chemical Vapor Deposition (CVD): Deposit thin films of magnetic materials onto substrates.

Additive Manufacturing (3D Printing):

Selective Laser Melting (SLM) or Electron Beam Melting (EBM): Build up layers of magnetic material in a controlled manner.

Applications:

Electronics:

Magnetic materials are used in transformers, inductors, and magnetic sensors.

Magnetic storage devices such as hard drives and magnetic tapes.

Medical Devices:

Magnetic nanoparticles are used in magnetic resonance imaging (MRI) and drug delivery systems.

Energy Conversion:

Permanent magnets in electric motors and generators.

Magnetic materials in energy harvesting devices.

Information Technology:

Magnetic materials play a crucial role in the development of spintronic devices.

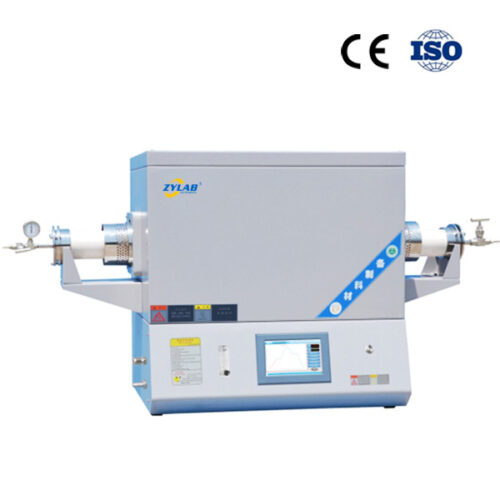

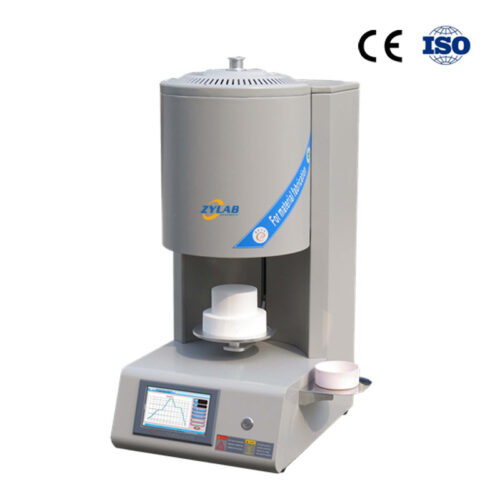

Related Products Recommend:

100-1200.C

100-1200.C