Ceramics and Target Material Preparation Solution

Ceramics and target material preparation are crucial processes in various industries, including manufacturing, electronics, energy, and aerospace.

Ceramics Manufacturing Process:

Raw Material Selection: Choose appropriate raw materials based on the desired properties.

Powder Preparation: Crushing and milling raw materials into fine powders.

Shaping: Form the ceramics using techniques like pressing, extrusion, or casting.

Drying: Remove excess moisture from shaped ceramics.

Sintering: Sinter the ceramics at high temperatures to achieve the final structure.

Target Material Preparation:

Target materials are substances used in various processes, such as sputtering, nuclear reactions, or irradiation.

Target Material Preparation Techniques:

Powder Metallurgy: Involves blending, compacting, and sintering powder materials.

Melt-Casting: Melting the material and casting it into the desired shape.

Chemical Vapor Deposition (CVD): Depositing a thin layer of material on a substrate.

Applications:

Thin Film Deposition: In electronics and optics.

Research: Production of isotopes for medical or scientific purposes.

Medical Treatment: Production of radioisotopes for cancer therapy.

Related Products Recommend:

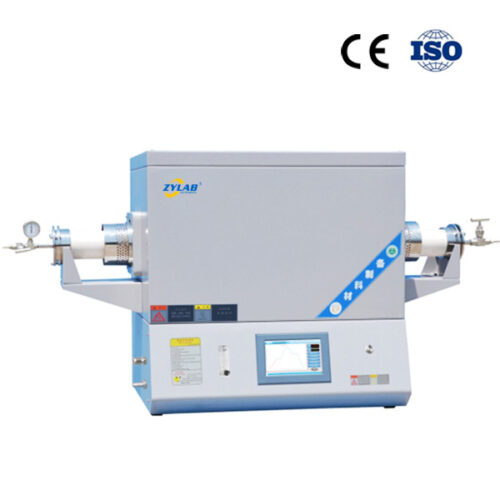

100-1200.C

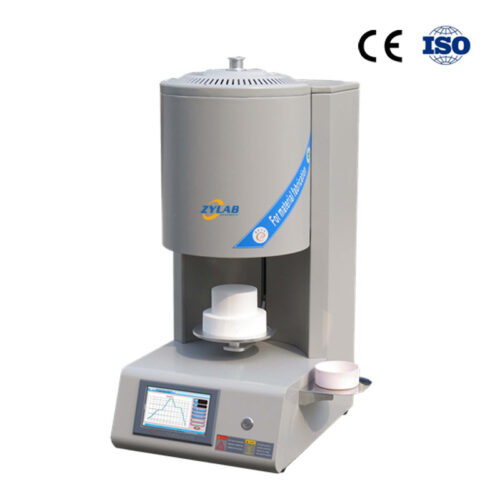

100-1200.C