Pouch Cell Preparation

Pouch cells are a type of rechargeable lithium-ion battery that is commonly used in various electronic devices. The term “pouch cell” refers to the packaging of the battery, which is typically a flexible pouch rather than a rigid metal can or cylindrical container.

The preparation of pouch cells involves several key steps, including cell assembly, electrolyte filling, sealing, and testing. Here is a general overview of the pouch cell preparation process:

-

Materials and Components:

- Positive electrode (cathode) material

- Negative electrode (anode) material

- Electrolyte solution

- Separator material

- Pouch cell packaging (flexible pouch)

-

Electrode Coating:

- The positive and negative electrode materials are typically coated onto metal foils. This can involve a slurry coating process, where a mixture of active material, conductive additives, and a binder is coated onto the foil.

-

Electrode Stacking:

- The coated positive and negative electrodes, along with separator material, are stacked together to form the electrode assembly.

-

Cell Assembly:

- The electrode assembly is placed into the pouch cell packaging.

- Tabs from the electrodes are connected to the external contacts for electrical connection.

-

Electrolyte Filling:

- The pouch cell is filled with the electrolyte solution. This electrolyte is a conductive solution that allows the flow of ions between the positive and negative electrodes during charging and discharging.

-

Sealing:

- The pouch is sealed to prevent leakage of electrolyte and to ensure a secure enclosure for the battery components. The sealing process is critical to maintain the integrity of the pouch cell.

-

Formation:

- The assembled and sealed pouch cell undergoes a formation process. Formation involves initial charge and discharge cycles to condition the battery and optimize its performance.

-

Aging and Testing:

- The pouch cells may undergo an aging process to simulate usage conditions and evaluate their long-term performance.

- Various tests, including capacity testing, cycle testing, and safety testing, are conducted to ensure the pouch cells meet quality standards.

-

Final Inspection:

- A final inspection is conducted to verify that each pouch cell meets the specified quality and safety standards.

Basic Process of Pouch Cell Preparation:

The exact details of pouch cell preparation may vary depending on the specific battery chemistry and intended application.

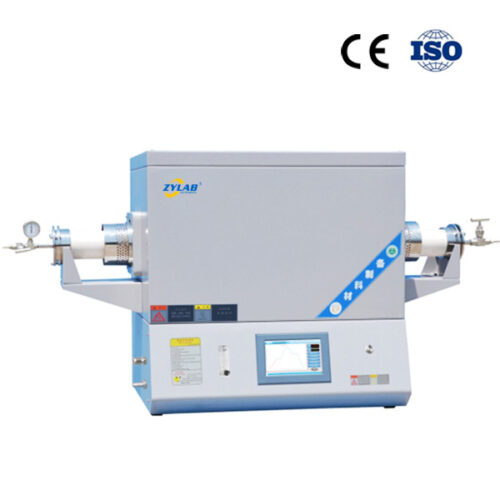

Equipment Recommend:

100-1200.C

800-1700.C

100-1200.C