Additive Manufacturing(3D Printing)

What is Additive Manufacturing?

Additive Manufacturing (AM), commonly known as 3D printing, is a process of creating three-dimensional objects by adding material layer by layer based on a digital model. Unlike traditional subtractive manufacturing methods, where material is removed from a solid block to create a desired shape, additive manufacturing builds objects from the ground up, offering unique advantages and applications.

Applications of Additive Manufacturing:

Prototyping: Additive manufacturing enables rapid prototyping, allowing designers and engineers to quickly iterate and test designs before moving to mass production.

Production Tooling: AM is employed to produce molds, jigs, and fixtures used in traditional manufacturing processes, reducing lead times and costs.

End-Use Parts: Additive manufacturing is increasingly being utilized for producing end-use parts across various industries, including aerospace, automotive, healthcare, and consumer goods.

Complex Geometry: It allows the creation of intricate and complex geometries that are difficult or impossible to achieve with traditional manufacturing methods, enabling lightweight designs and improved performance.

Spare Parts Manufacturing: Additive manufacturing facilitates on-demand production of spare parts, reducing inventory costs and lead times.

Low-Volume Production: AM is suitable for low-volume production runs where traditional manufacturing methods are economically unfeasible.

Education and Research: It’s used in educational institutions and research facilities to teach principles of design and manufacturing and explore new materials and processes.

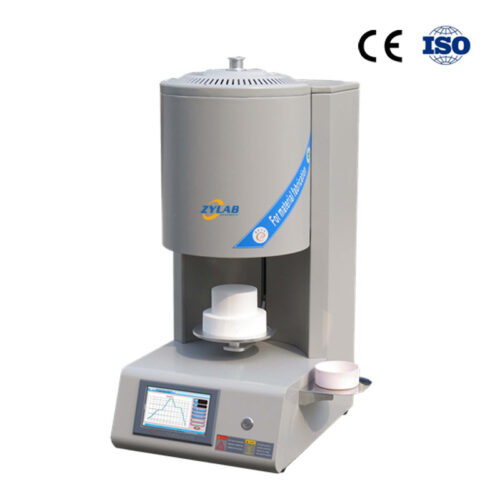

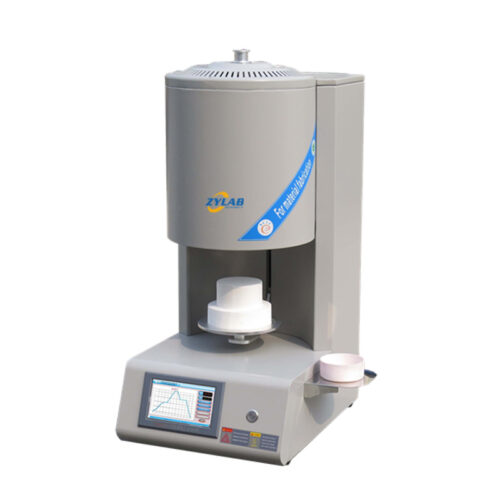

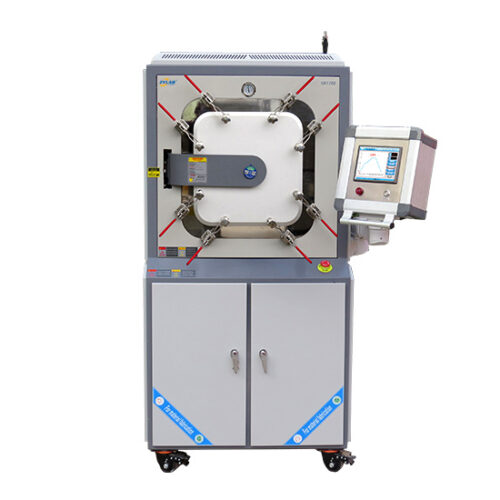

ZYLAB provides various supporting sintering furnaces for the R&D of additive manufacturing. Here, you will find information on different sintering furnace types, sizes, along with their unique features and sintering capabilities.

ZYLAB experts team always ready to assist you find the perfect solution for your sintering processes. If you have a requirement, contact us now!

Related Products Recommend:

100-1200.C

100-1200.C

500-1500.C