At ZYLAB, we take pride in supporting academic excellence by delivering high-quality laboratory equipment to leading universities around the world. We are pleased to announce the successful delivery of a planetary ball mill to the prestigious University of Southampton in the United Kingdom.

About the University of Southampton

The University of Southampton is consistently ranked among the top research universities in the UK, recognized globally for its contributions in engineering, materials science, and nanotechnology. As a member of the Russell Group, the university maintains high standards of academic research and innovation.

Meeting the Needs of Advanced Materials Research

Researchers at Southampton were looking for a high-performance milling solution. Our ZYLAB planetary ball mill was selected due to its:

- Precision control over speed and time

- Programmable rotation and revolution cycles

- High grinding efficiency and uniform particle size

- Robust build and reliable safety features

With its compact design and powerful performance, the equipment integrates seamlessly into the university’s laboratory environment, supporting both postgraduate research and academic projects.

Why ZYLAB?

At ZYLAB, we focus on providing customizable, high-precision lab equipment that meets the needs of modern research. Our planetary ball mills are widely used across universities, research institutes, and industrial R&D departments worldwide. Each unit is built with:

- Advanced motor and inverter technology

- High performance with various jar material options, including stainless steel, agate, and zirconia.

- Customizable capacity from 0.4L to 100L

- Intelligent control system with programmable logic

We also provide responsive technical support, detailed operation manuals, and fast international shipping, ensuring a smooth experience from inquiry to installation.

Supporting Global Science Through Partnership

Our collaboration with the University of Southampton reflects ZYLAB’s ongoing commitment to facilitating groundbreaking research through reliable and innovative equipment. We believe in forming long-term partnerships with academic institutions, enabling researchers to focus on discovery and innovation without worrying about equipment performance.

Looking Forward

We’re proud to see our planetary ball mill contribute to research at one of the UK’s top universities. If you’re seeking advanced grinding and mixing solutions for your laboratory, feel free to contact us. We’re here to help you find the most suitable solution for your specific research goals.

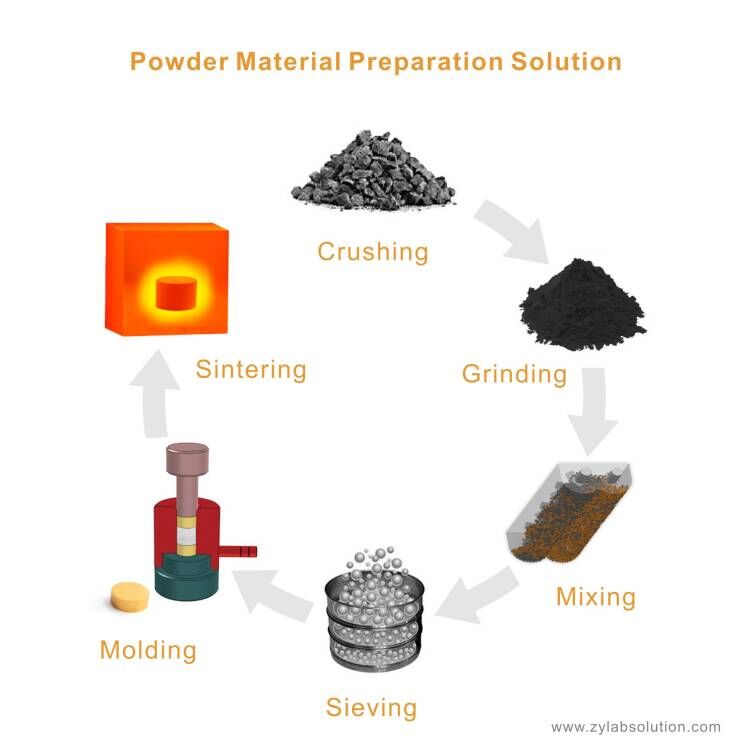

One-Stop Powder Solutions

In addition to high-quality grinding /milling equipment, ZYLAB offers comprehensive one-stop powder solutions tailored to diverse research needs. To explore advanced powder processing techniques and their applications, read our full article here.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!