Table of Contents

The Plasma-Enhanced Chemical Vapor Deposition (PECVD) system is widely utilized in various industries and research fields for diverse applications. Here are some common applications:

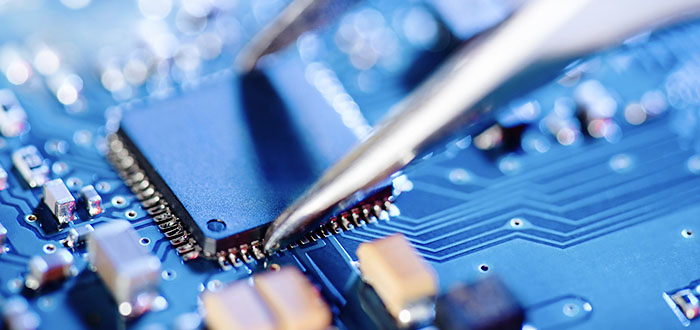

Semiconductor Manufacturing

PECVD is extensively used in the semiconductor industry for depositing thin films on silicon wafers. It is employed in the fabrication of integrated circuits, microelectromechanical systems (MEMS), and other semiconductor devices.

Solar Cell Production

PECVD plays a crucial role in the manufacturing of thin-film solar cells. It is used to deposit various layers, such as amorphous silicon or silicon nitride, contributing to the efficiency and performance of solar panels.

Optical Coatings

PECVD is utilized for applying thin films on optical components like lenses and mirrors. It helps enhance the reflectivity, anti-reflective properties, and durability of optical coatings.

Flat Panel Display Manufacturing

PECVD is employed in the production of flat panel displays, including liquid crystal displays (LCDs) and organic light-emitting diode (OLED) displays. It is used to deposit thin films that enhance the performance and characteristics of display technologies.

Microelectronics and MEMS Devices

PECVD is crucial in the fabrication of microelectronics and MEMS devices. It is used to deposit insulation and passivation layers, as well as sacrificial layers in MEMS processes.

Barrier Coatings

PECVD is used to deposit barrier coatings that prevent the diffusion of gases or contaminants. This is important in applications where maintaining a specific environment or preventing corrosion is critical.

Biomedical Applications

In biomedical research, PECVD is employed to coat substrates with bio-compatible materials. This can include creating surfaces for cell culture, drug delivery systems, or bio-sensors.

Gas Barrier Films

PECVD is used to create gas barrier films, which are crucial in packaging materials to prevent the permeation of gases such as oxygen and moisture. This is important in preserving the quality and shelf life of food and pharmaceutical products.

Hard Coatings

PECVD is utilized to deposit hard coatings on materials, providing enhanced wear resistance and durability. This is applicable in cutting tools, automotive components, and various industrial applications.

Decorative Coatings

PECVD is employed for decorative coatings on glass and other materials. It enhances aesthetics while providing functional properties like scratch resistance.

The versatility of PECVD systems makes them indispensable in advancing technology and innovation across a broad spectrum of industries.