Table of Contents

Introduction

LED phosphors play a critical role in the efficiency and performance of modern LED lighting and display technologies. High-quality LED phosphors enhance color rendering, brightness, and energy efficiency. The production of LED phosphors involves precise thermal processing to achieve the desired crystalline structure and optical properties.

A large-diameter tube furnace offers a controlled environment for high-temperature processing, enabling uniform heating, scalable production, and atmosphere control.

This article explores how a large-diameter tube furnace optimizes LED phosphor production and its advantages over conventional methods.

Why Do LED Phosphors Require High-Temperature Heat Treatment?

LED phosphors require high-temperature heat treatment to achieve the necessary crystal structure, purity, and stability for optimal optical performance. The key reasons include:

- Phase Formation and Crystallization: Many LED phosphor materials, such as YAG-based and nitride phosphors, require temperatures above 1000°C to form the correct crystalline phases that ensure high quantum efficiency.

- Enhancement of Luminescent Properties: High-temperature synthesis helps in reducing structural defects and improving the phosphor’s light-conversion efficiency.

- Removal of Impurities: Heat treatment in a controlled atmosphere eliminates unwanted volatile components and enhances material purity.

Improvement of Thermal - Stability: Proper annealing strengthens the phosphor’s resistance to heat degradation, ensuring a longer lifespan in LED applications.

The Importance of LED Phosphors in Lighting Technology

LED phosphors are used to convert blue or near-ultraviolet light into visible white light in LED applications. They are commonly composed of materials such as:

- YAG (Yttrium Aluminum Garnet): Used for warm and cool white LEDs.

- Nitride-based phosphors: Provide red and orange emissions.

- Silicate-based phosphors: Offer improved color rendering.

The quality of LED phosphors depends on their crystal structure, particle size, and purity, which are significantly influenced by the thermal processing conditions.

Why Use a Large-Diameter Tube Furnace for LED Phosphor Production?

A large-diameter tube furnace provides several advantages in the synthesis and heat treatment of LED phosphors:

1. Uniform Heating and Temperature Control

- Equipped with multi-zone heating elements, a large-diameter tube furnace ensures uniform temperature distribution inside the furnace.

- Intelligent PID fuzzy control provides precise temperature adjustments, reducing thermal fluctuations and improving product consistency.

2. Large-Scale Production Capability

- The increased tube diameter allows for the processing of larger batches, improving manufacturing efficiency.

- Enables continuous processing, reducing production downtime compared to batch-based furnaces.

3. Atmosphere Control for Improved Material Properties

- The furnace supports vacuum and controlled gas atmospheres (e.g., nitrogen, argon, hydrogen), preventing oxidation and enhancing phosphor stability.

- Constant pressure regulation ensures optimal conditions for chemical reactions during synthesis.

4. Enhanced Energy Efficiency

- High-purity Al2O3 fiber insulation minimizes heat loss, reducing power consumption.

- A double-layer air-cooled structure keeps the furnace’s exterior cool, improving energy efficiency and operator safety.

Key Technical Features of a Large-Diameter Tube Furnace

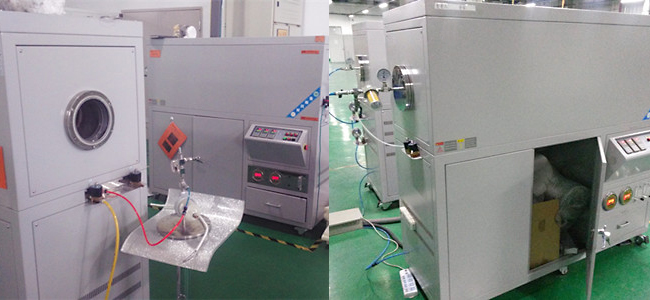

ZYLAB’s large-diameter tube furnace is designed for advanced material processing and offers the following technical benefits:

- Extra-large tube diameter and extended heating zones for better heat uniformity.

- Multi-point temperature measurement and PID fuzzy control ensure stable and precise temperature regulation.

- High-purity quartz furnace tubes suitable for both vacuum and atmosphere-controlled heat treatments.

- Constant pressure system to maintain stable internal conditions during processing.

- Quick-opening stainless steel sealing flanges for efficient loading and unloading of materials.

Key Steps in LED Phosphor Production Using a Large-Diameter Tube Furnace

The production of LED phosphors typically involves the following steps:

1. Raw Material Preparation

- High-purity precursors, such as rare earth oxides and nitride powders, are mixed in precise ratios.

- The material may be pre-treated with a binder to enhance particle uniformity.

2. High-Temperature Solid-State Reaction

- The powder mixture is loaded into crucibles or ceramic trays inside the large-diameter tube furnace.

- The material is heated at 900–1400°C depending on the phosphor composition.

Controlled heating rate (≤20°C/min) prevents thermal shock and promotes uniform grain growth.

3. Atmosphere Processing for Optimal Performance

- Depending on the phosphor type, the furnace may use a reducing atmosphere (e.g., H2/N2) to prevent oxidation.

- A vacuum or inert gas atmosphere is maintained to enhance phase purity and prevent unwanted side reactions.

4. Cooling and Post-Processing

- After the high-temperature process, the phosphor materials are slow-cooled to prevent structural defects.

- Post-processing includes milling, sieving, and surface coating to optimize particle size and improve dispersibility.

Case Study: Improving Red LED Phosphors with a Large-Diameter Tube Furnace

A study on nitride-based red LED phosphors demonstrated that using a large-diameter tube furnace improved:

- Luminous efficiency by 15% due to better phase purity.

- Thermal stability, leading to enhanced lifespan in high-power LED applications.

- Production yield, enabling manufacturers to scale up production while maintaining consistent quality.

Conclusion

The large-diameter tube furnace is an essential tool for optimizing LED phosphor production. With its superior temperature uniformity, large-scale capacity, atmosphere control, and energy efficiency, it outperforms traditional small-scale furnaces.

By adopting this advanced thermal processing technology, manufacturers can enhance the quality, efficiency, and scalability of LED phosphor production, ultimately leading to better-performing LED lighting and display technologies.

For those looking to improve their LED phosphor synthesis process, integrating a large-diameter tube furnace is a cost-effective and technologically advanced solution.

For more information or technical support, feel free to contact ZYLAB.

Share this entry

You might also like