Table of Contents

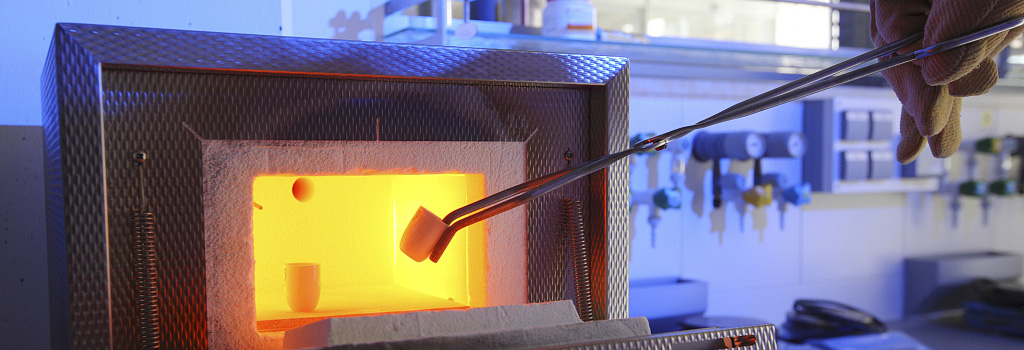

Laboratory electric furnace is a type of heating device, used in scientific research, materials processing, and quality control applications. It use electricity to generate heat, which is then transferred to the sample through conduction, convection, or radiation.

The Working Principle of Laboratory Electric Furnace

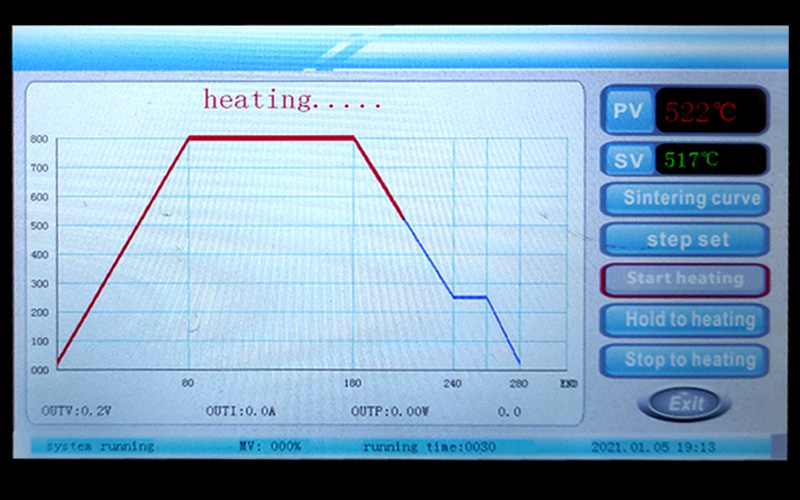

Clear heating curves ; can store temperature curves to avoid the trouble caused by repeated settings of different experimental processes. Very easy to use and it’s simple and practical for your laboratory heating treatment problem.

The Classifications of Laboratory Electric Furnaces

Laboratory electric furnaces can be classified based on several factors, including the heating element, temperature range, design, and features.

1. Based on the heating element, common classifications include:

- Resistance wire furnaces: These furnaces use a heating element made of a resistance wire, such as nichrome or kanthal, that is wound around a ceramic or metal core. They can typically achieve temperatures up to 1200°C.

- Silicon carbide (SiC) furnace: These furnaces use a heating element made of SiC, a high-temperature ceramic material. They can typically achieve temperatures up to 1500°C.

- Molybdenum disilicide (MoSi2) furnaces: These furnaces use a heating element made of MoSi2, a high-temperature ceramic material. They can typically achieve temperatures up to 1700°C.

2. Based on the temperature range, common classifications:

- Low-temperature furnaces (up to 1200°C).

- Medium-temperature furnaces (up to 1500°C).

- High-temperature furnaces (up to 1700°C).

3. Based on the design, common classifications include:

- Box furnaces(also named Muffle Furnaces, Chamber Furnaces): Have a rectangular or square shape and are used for batch processing or for heating larger samples.

- Tube furnaces: Have a cylindrical chamber, includs two types: horizontal and vertical, and horizontal tube furnaces are more commonly used. Mainly used for heating smaller samples or for applications that require a continuous flow of gas.

- Split tube furnaces: Are similar to tube furnaces, but have a split design that allows for easier loading and unloading of samples.

- Multi-zone furnaces: Have multiple heating zones that can be independently controlled, allowing for more precise temperature control.

- Vacuum furnaces: Are used for processing samples under low-pressure conditions, such as for heat treatment or sintering.

4. Based on features, common classifications include:

- Atmosphere-controlled furnaces: Can control the gas atmosphere in the furnace chamber to create an inert, reducing, or oxidizing environment.

- Rapid heating and cooling furnaces: Can achieve high heating rates and quenching to rapidly change the temperature of the sample.

- Programmable furnaces: Have advanced temperature, time, and ramp/soak control features, allowing for precise control of heating and cooling profiles. (ZYLAB furnaces are all come with programmable feature.)

- Ashing furnaces: For removing organic materials from samples, such as in elemental analysis or soil testing.

Overall, ZYLAB experts will help researchers and technicians to select the appropriate furnace for their specific application, based on the temperature requirements, sample size and type, and other experimental parameters.