Introduction

Cement calcination is a critical process in both industrial production and laboratory research. Accurate calcination is essential for determining the quality, strength, and chemical composition of cement materials.

In laboratory settings, the muffle furnace is an indispensable tool for precise and controlled cement calcination. This blog explores how to use a muffle furnace for cement calcination, the typical temperature ranges, best practices, common challenges, and how to improve test accuracy.

What Is Cement Calcination?

Cement calcination refers to the thermal decomposition and chemical transformation of raw materials such as limestone and clay into cement clinker. The process involves several thermal stages:

-

At 850–950°C: Carbonates decompose, releasing carbon dioxide.

-

At around 1200°C: Partial melting begins, facilitating mineral reactions.

-

At 1450°C: Full clinker formation occurs, producing key minerals like tricalcium silicate (C₃S), which contribute to the final strength of cement.

In industrial production, 1450°C is the target temperature for clinker manufacturing inside rotary kilns.

In laboratory environments, depending on the objective, different temperature settings are used:

| Purpose | Typical Temperature Range | Required Equipment |

| Cement Raw Material Decomposition (LOI Testing) | 900–1100°C | Standard Muffle Furnace |

| Partial Calcination (Early Stage Testing) | 1000–1200°C | Standard Muffle Furnace |

| Complete Clinker Formation | 1400–1450°C | High-Temperature Furnace (>1600°C Capability) |

Note: Standard muffle furnaces are ideal for loss on ignition (LOI) and partial calcination tests but not sufficient for full clinker synthesis at 1450°C.

Why Use a Muffle Furnace for Cement Calcination?

Using a muffle furnace provides several advantages for cement testing:

-

Precise Temperature Control:

Ensures stable heating and minimizes sample variability. -

Clean and Controlled Environment:

The enclosed chamber prevents contamination during high-temperature reactions. -

Efficient and Repeatable Testing:

Rapid heating/cooling cycles improve laboratory productivity compared to traditional kilns.

Key Parameters for Cement Calcination in a Muffle Furnace

Achieving accurate calcination results requires careful control of:

-

Temperature Setting:

Typical laboratory calcination for cement samples is set between 850°C and 1100°C. -

Heating Rate:

A gradual ramp of 5–10°C per minute helps prevent thermal shock and cracking. -

Soaking Time:

Samples are usually held at peak temperatures for 30 minutes to 2 hours depending on the material and purpose. -

Atmosphere Conditions:

Calcination is typically performed in air; however, some advanced tests may benefit from atmosphere-controlled furnaces.

Common Challenges in Cement Calcination and How to Solve Them

Even in laboratory settings, cement calcination presents challenges:

-

Temperature Fluctuations:

Uneven heating can result in incomplete reactions. ZYLAB muffle furnaces feature high heating uniformity, ensuring consistent calcination results across the entire chamber. -

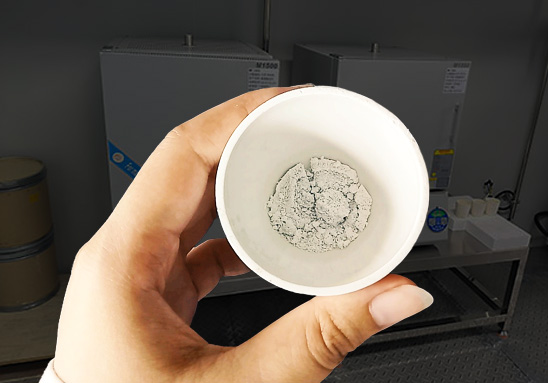

Sample Contamination:

Using improper crucibles can alter cement chemistry. ZYLAB recommends high-purity alumina crucibles, ideal for cement calcination due to their excellent chemical stability and resistance to high temperatures. -

Gas Emissions Management:

Decomposition of cement raw materials releases gases. ZYLAB furnaces are equipped with a top exhaust chimney for safe and efficient gas discharge during calcination. -

Sample Overheating or Sintering:

Accurate PID temperature control in ZYLAB muffle furnaces prevents unintentional sintering or overheating, ensuring sample integrity.

Conclusion

The use of a reliable, precision-controlled muffle furnace is essential for achieving accurate cement calcination in laboratory settings.

For applications involving raw material analysis, loss on ignition, or partial calcination, a high-performance muffle furnace like those from ZYLAB delivers consistent, accurate, and efficient results.

When complete clinker formation is required (up to 1450°C), a high-temperature furnace capable of exceeding 1600°C becomes necessary.

Choosing ZYLAB muffle furnaces — with their excellent temperature uniformity, optional atmosphere control, custom chamber designs, and high-purity alumina crucibles — ensures that your cement analysis is both accurate and efficient.

Are you looking for a high-performance muffle furnace or high-temperature solution for cement calcination? Contact ZYLAB today for expert consultation, customized options, and premium ceramic accessories.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!

Share this entry

You might also like