Table of Contents

Overview

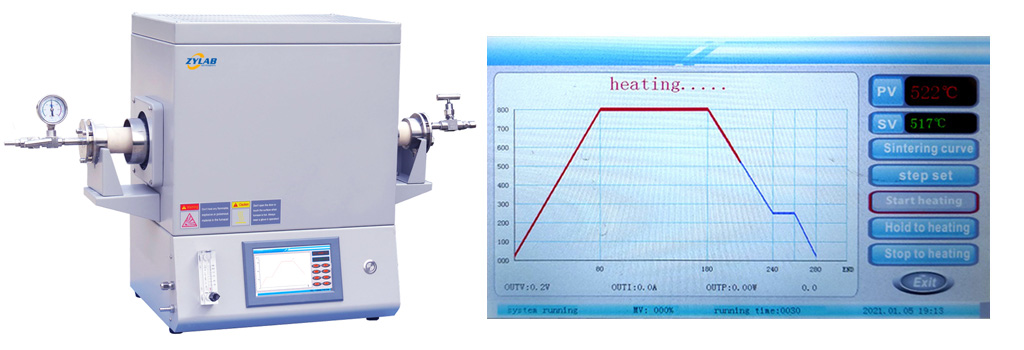

A horizontal tube furnace is a specialized heating device used for high-temperature applications in laboratories, research, and industry. Unlike traditional vertical tube furnaces, this type of furnace features a horizontal orientation, making it suitable for processes that require horizontal positioning of samples.

Horizontal tube furnaces typically consists of a cylindrical heating chamber with an integrated heating element and precise temperature control.It’s designed is to achieve precise temperature control and uniform heating for a wide range of applications.

Features

Horizontal Orientation: The furnace chamber is aligned horizontally, allowing for the placement of samples in a horizontal position.

High-Temperature Capability: Horizontal tube furnaces can achieve temperatures well above 1000°C, depending on the model.

Precise Temperature Control: They offer accurate temperature control through integrated controllers or software.

Uniform Heating: The design ensures even temperature distribution along the length of the tube.

Safety Features: Many models come with safety features such as over-temperature protection and interlocks.

Work Process

1. Samples or materials are loaded into a tube or container within the horizontal furnace chamber.

2. The heating elements are activated, and the temperature is gradually raised to the desired level.

3. The materials undergo the required processes with precise temperature control and uniform heating.

4. After the process is complete, the furnace is allowed to cool down before samples are removed.

Applications

Materials Processing: Used for sintering, annealing, and heat treatment of ceramics, metals, and semiconductors.

Chemical Reactions: Facilitates processes such as chemical vapor deposition (CVD), thermal decomposition, and materials synthesis.

Materials Research: Employed for materials characterization, crystal growth, and catalyst testing.

Sample Preparation: Suitable for ashing, drying, and pre-processing of samples for analytical techniques.

Benefits

1. Ideal for applications that require horizontal sample positioning.

2. Precise control of temperature for consistent results.

Uniform heating along the length of the tube.

3. Versatile and adaptable for various laboratory and industrial applications.

Price

The price of a horizontal tube furnace can vary significantly based on factors such as temperature range, tube material, size, and additional features. Basic models may start at a few thousand dollars, while more advanced and larger furnaces can cost tens of thousands of dollars or more.

Considerations When Purchasing

Temperature Range: Ensure the furnace can achieve the required temperature for your specific applications.

Tube Material: Select the appropriate tube material (e.g., alumina, quartz, or ceramic) based on sample compatibility.

Temperature Control System: Evaluate the precision and ease of use of the temperature control system.

Safety Features: Consider safety features like over-temperature protection and emergency shut-off systems.

Size and Capacity: Choose a model that can accommodate your sample size and quantity.

Atmosphere Control: Determine if you need the furnace to operate in a controlled atmosphere, such as inert gas or vacuum.

Supplier Reputation: Research and select a reputable supplier with professional knowledge.

FAQ

1. Can I use a horizontal tube furnace for controlled atmosphere experiments?

Yes, many models can be equipped with controlled atmosphere capabilities, such as inert gas or vacuum.

2. What maintenance is required for a horizontal tube furnace?

Regular cleaning and inspection are necessary. Follow the manufacturer’s guidelines for maintenance procedures.

3. Can I observe the sample inside the horizontal tube furnace during heating?

Some models with quartz tube can observe the sample inside the horizontal tube furnace during heating.

4. What’s the difference between a horizontal tube furnace and a vertical tube furnace?

The primary difference is the orientation of the heating chamber. Horizontal tube furnaces are designed for applications that require horizontal sample positioning, while vertical tube furnaces have a vertical configuration. The choice depends on the specific application requirements.