Introduction

Molybdenum (Mo) alloys are widely used in high-temperature applications due to their excellent mechanical strength, corrosion resistance, and thermal stability. Developing advanced Mo alloys requires precise control over the alloying process, and this is where the High Vacuum Tungsten Wire Furnace becomes indispensable.

In this blog, we will explore the key role of this specialized furnace in molybdenum alloy research, focusing on its features, benefits, and practical applications.

Why Use a High Vacuum Tungsten Wire Furnace?

The High Vacuum Tungsten Wire Furnace is designed specifically for materials that require ultra-high-temperature processing under a vacuum or inert atmosphere. In the context of molybdenum alloy preparation, this furnace offers the following advantages:

-

High-Temperature Capability:

-

The furnace can reach temperatures up to 2200°C, which is crucial for the sintering and melting of molybdenum and its alloys.

-

Such high temperatures enable the formation of dense and homogenous alloy structures.

-

-

Ultra-High Vacuum Environment:

-

The vacuum environment (up to 6.67 × 10⁻³ Pa) minimizes oxidation and contamination during processing.

-

This feature is particularly important for molybdenum, as it easily oxidizes at elevated temperatures.

-

-

Precise Temperature Control:

-

Equipped with tungsten-rhenium thermocouples, the furnace ensures accurate temperature measurement, which is critical for maintaining consistent alloy properties.

-

-

Inert Gas Atmosphere:

-

The furnace supports the use of argon, nitrogen, or dry hydrogen, preventing unwanted chemical reactions during heating.

-

This atmosphere is ideal for maintaining molybdenum’s purity.

-

Applications in Molybdenum Alloy Research

The High Vacuum Tungsten Wire Furnace plays a vital role in several stages of molybdenum alloy development:

-

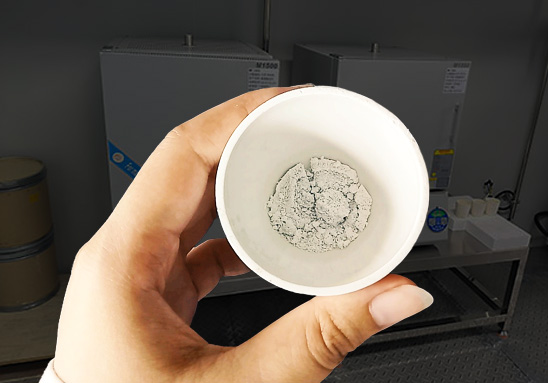

Sintering of Molybdenum Powder:

-

Achieving high-density sintered bodies is essential for creating Mo alloys with superior mechanical properties.

-

The vacuum and high temperature reduce impurity content, resulting in alloys with excellent strength and thermal conductivity.

-

-

Alloy Element Diffusion:

-

Uniform diffusion of alloying elements like tungsten (W), titanium (Ti), and zirconium (Zr) is crucial.

-

The furnace’s precise temperature control ensures homogenous alloy formation, crucial for research aiming to improve high-temperature performance.

-

-

Vacuum Melting and Casting:

-

The furnace’s ability to melt molybdenum alloys under vacuum prevents the formation of oxides, thus improving chemical purity and mechanical integrity.

-

This process is particularly relevant when developing Mo-based superalloys for aerospace and energy applications.

-

-

Heat Treatment of Mo Alloys:

-

Controlled heat treatment can enhance the ductility and tensile strength of Mo alloys.

-

The furnace provides a stable environment for annealing, stress relieving, and recrystallization processes.

-

Enhancing Research Efficiency

Using a High Vacuum Tungsten Wire Furnace in molybdenum alloy research can significantly improve:

-

Data Accuracy: Stable temperature and vacuum conditions yield reliable experimental results.

-

Process Efficiency: Automated control systems enable programmable heating profiles, reducing human error and enhancing reproducibility.

-

Safety and Durability: The robust design, including graphite or tungsten heating elements, ensures long-term stable operation even under extreme conditions.

Conclusion

The High Vacuum Tungsten Wire Furnace has proven indispensable in molybdenum alloy research, providing the necessary environment to achieve precise and high-quality results. Its advanced features and robust construction make it ideal for processes such as sintering, alloy element diffusion, vacuum melting, and heat treatment of Mo alloys.

If you are looking for a reliable and high-performance furnace to enhance your molybdenum alloy research, the ZYLAB High Vacuum Tungsten Wire Furnace is your best choice. With proven efficiency, superior quality, and cutting-edge technology, ZYLAB furnaces ensure accurate results and long-term stability.

Contact us now to learn more about the ZYLAB High Vacuum Tungsten Wire Furnace. Let us help you achieve breakthrough results in molybdenum alloy development!

Share this entry

You might also like