Table of Contents

Glass reactor is an apparatus used for chemical reactions and experiments, characterized by its vessel being made of glass. This design allows for visual observation of the reaction process, and in certain cases, glass materials exhibit good compatibility with certain chemical reactions.

Components of Glass Reactors

Vessel Body: The main part of the reaction kettle is usually made of glass, providing transparency for experimenters to visually observe the reaction process, facilitating experimental control and monitoring.

Base: The reaction kettle is typically placed on a supportive base to ensure stability.

Heating Device: To control the reaction temperature, glass reaction kettles are equipped with a heating device, which can be an external electric heating jacket or other forms of heating systems.

Stirring System: To promote uniform mixing of reactions, a stirring system is often configured inside the reaction kettle, utilizing stirring blades, magnetic stirrers, or other stirring devices.

Cooling System: In some reactions, temperature control may require cooling. Therefore, glass reaction kettles can be equipped with a cooling system, typically achieved through external circulating cooling water.

Inlet and Outlet Ports: Reaction kettles usually have inlet and outlet ports for adding raw materials and extracting reaction products.

Accessories: Depending on specific experimental requirements, glass reaction kettles may be equipped with various accessories such as temperature probes, flow meters, vacuum connectors, etc.

Classification by Structure

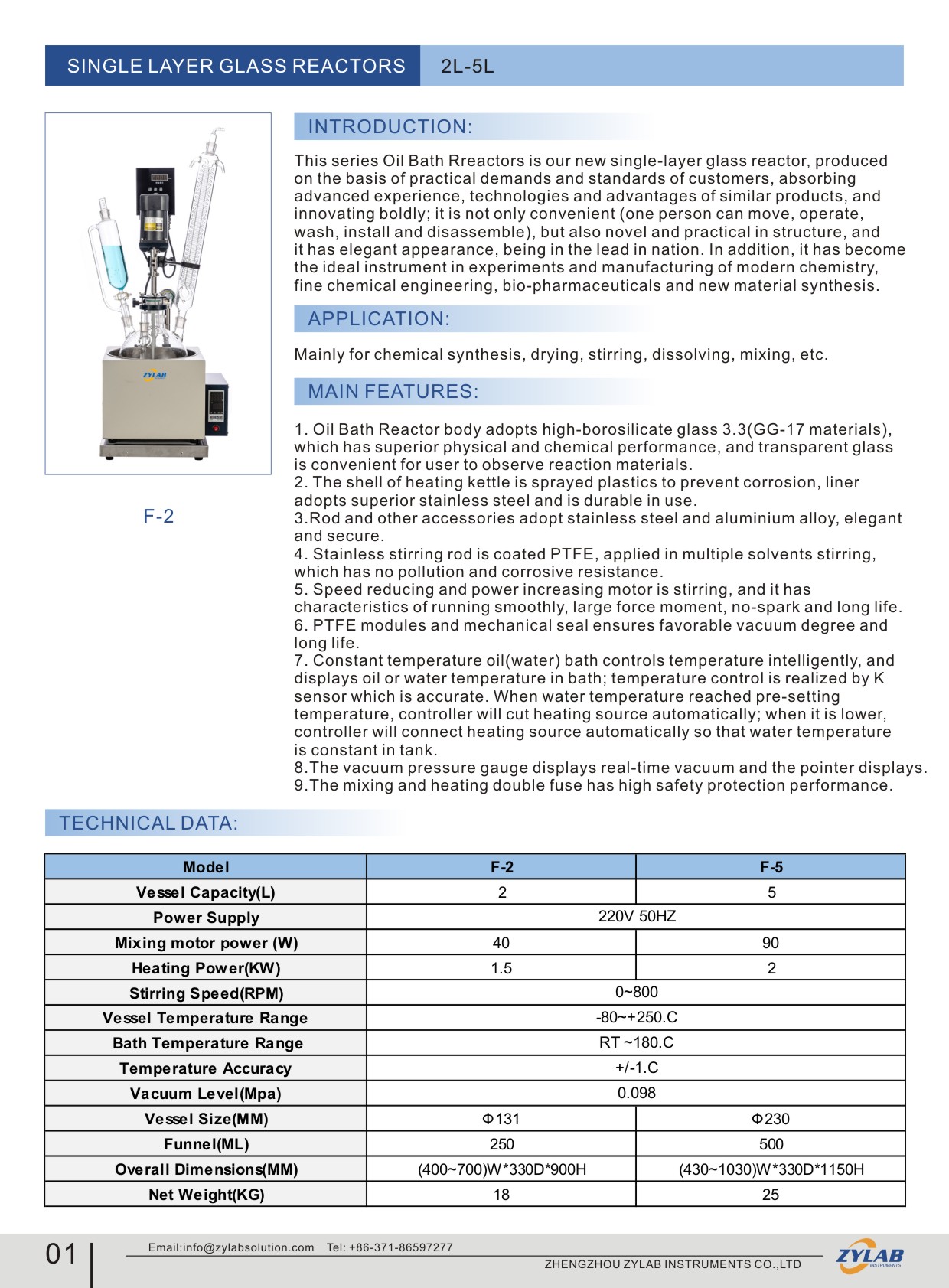

Single Layer Glass Reactors:

Simple Structure: The structure of a single-layer glass reaction kettle is relatively simple, usually consisting of a single-layer glass vessel.

Applicability: Primarily suitable for general laboratory requirements where temperature and pressure conditions are not particularly stringent.

Heating Method: Heating is carried out using external electric heating jackets or similar methods.

Visibility: Exhibits good transparency, allowing experimenters to visually observe the reaction process.

Jacketed Glass Reactors:

Jacket Structure: The double-layer jacketed glass reaction kettle has a space between the outer and inner layers, which serves as a jacket that can be used for fluid circulation, achieving more precise control of reaction temperature.

Temperature Control: Provides better temperature control performance, suitable for temperature-sensitive experiments.

Explosion-Proof Design: Some designs of double-layer jacketed glass reaction kettles have explosion-proof features, enhancing safety.

Wide Application: Suitable for experiments requiring more precise control of reaction conditions, high-temperature and high-pressure reactions, or experiments requiring cooling.

Common Applications of Glass Reactors

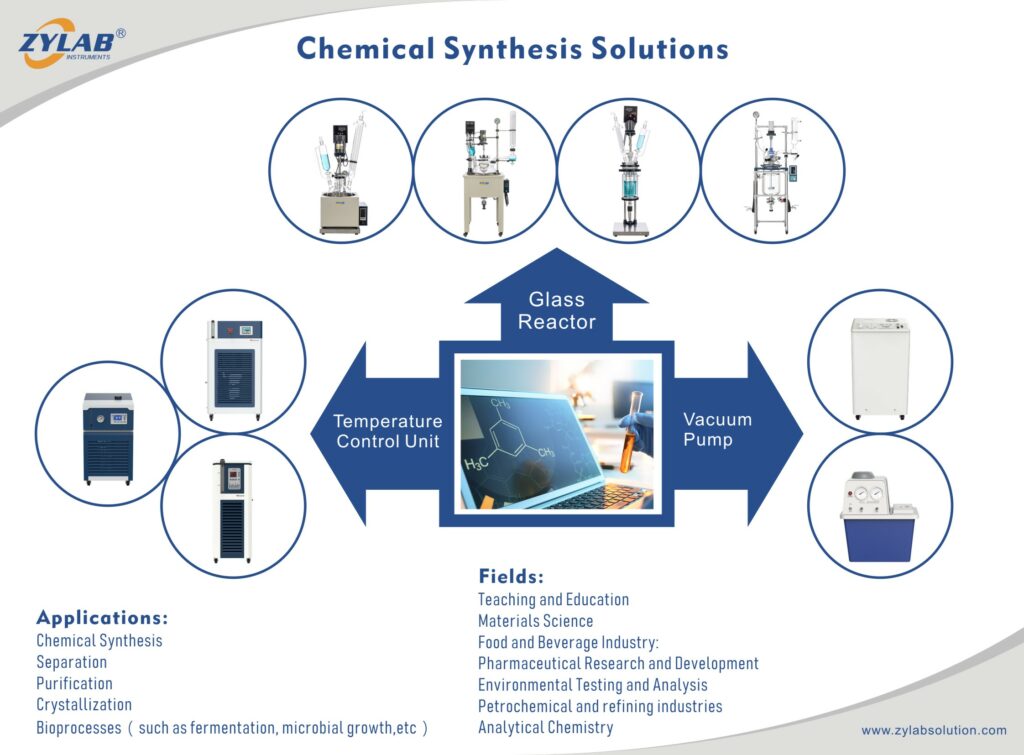

Chemical Synthesis: Glass reactors are widely used in chemical laboratories and industries for the synthesis of new chemicals, organic compounds, and pharmaceutical intermediates. Researchers can observe and control the reaction progress and optimize reaction conditions.

Distillation: Glass reactors are employed for fractional distillation, which is essential in the separation and purification of components in a mixture. They can be used for distillation of solvents, separation of volatile components, and purification of substances.

Crystallization: Glass reactors are used to induce and control the crystallization of compounds. Researchers can monitor the growth of crystals and optimize conditions for larger and purer crystal formation.

Extraction: Glass reactors are utilized for solvent extraction processes, such as liquid-liquid extraction and solid-liquid extraction. They are commonly used in analytical chemistry for sample preparation.

Reactor Systems: Glass reactors can be used as reaction vessels in pilot plants or small-scale production facilities for various chemical processes, including polymerization, hydrogenation, oxidation, and more.

Bioprocesses: In biotechnology and biochemistry, glass reactors are used for bioprocesses such as fermentation, microbial growth, and cell culture. Their transparency is particularly useful for observing cell growth and ensuring sterility.

Food and Beverage Industry: Glass reactors are used for various processes in the food and beverage industry, such as fermentation, enzymatic reactions, and flavor extraction.

Pharmaceutical Research and Development: Glass reactors are essential in pharmaceutical research for API (Active Pharmaceutical Ingredient) development, process optimization, and the synthesis of pharmaceutical compounds.

Environmental Testing and Analysis: Glass reactors are employed in environmental laboratories for testing and analyzing water, soil, and air samples, including tests like BOD (biochemical oxygen demand), COD (chemical oxygen demand), and wastewater treatment studies.

Teaching and Education: Glass reactors serve as valuable teaching tools in educational institutions and teaching laboratories, where they are used to demonstrate various chemical and biological processes to students.

Materials Science: Glass reactors are used for the synthesis and processing of advanced materials, including nanoparticles, nanocomposites, and specialty glasses.

Environmental Remediation: They are used in environmental engineering for processes like photocatalytic degradation of pollutants, testing of new remediation methods, and the removal of contaminants from water or soil.

Catalyst Development: Glass reactors are essential for studying and developing catalysts used in various chemical processes, including petrochemical and refining industries.

Analytical Chemistry: Glass reactors can be employed in analytical chemistry for sample digestion, extraction, and preparation processes.

Nanotechnology: Glass reactors play a role in the synthesis and manipulation of nanomaterials and nanocomposites due to their precise control over reaction conditions.

Applications in Environmental Science Research

Water Chemistry Studies: Glass reactors can be utilized to simulate chemical reactions in water, investigating the chemical properties of water, behavior of dissolved substances, and the migration, transformation, and degradation processes of pollutants in water quality.

Soil Chemistry Research: In environmental science, reactors are employed to simulate chemical processes in soil, studying the behavior of pollutants in soil, migration pathways, and interactions with soil particles.

Wastewater Treatment Research: Reactors play a crucial role in wastewater treatment research. Through reactor experiments, scientists can simulate various wastewater treatment processes, including chemical precipitation, adsorption, oxidation-reduction reactions, to reduce concentrations of harmful substances in wastewater.

Atmospheric Chemistry Studies: Used to simulate chemical reactions in the atmosphere, studying the generation, transformation, and elimination of pollutants in the air. Reactors help scientists understand chemical processes in the atmosphere, such as the formation mechanisms of acid rain.

Ecotoxicology Experiments: Glass reactors are employed in ecotoxicology research to simulate pollution scenarios in the environment, studying the toxic effects of pollutants on organisms within ecosystems.

Research on the Environmental Behavior of Novel Materials: In the field of environmental science, studying the behavior of novel materials (e.g., nanomaterials) in the environment is essential. Reactors can simulate the environmental impact of these materials, including their interactions in water or soil.

Pollutant Migration Studies: Reactors can be used to study the migration pathways of pollutants in the environment, including processes such as dissolution, adsorption, and deposition, aiding in predicting and assessing environmental pollution.

Applications in Battery Development

Synthesis of Battery Materials: Glass reactors are employed in the synthesis of various materials used in batteries, including cathode materials (e.g., oxides, sulfides), anode materials (such as graphite, silicon), and electrolytes. Reactors provide a controlled environment for temperature and reaction conditions, ensuring the precision and reproducibility of synthesis reactions.

Modification Studies of Battery Materials: In battery development, research on modified materials aims to improve battery performance, increase cycle life, and enhance safety. Glass reactors are used to synthesize and study modified battery materials, exploring the effects of different additives, coatings, etc., on battery performance.

Characterization and Analysis of Battery Materials: Glass reactors facilitate sample preparation for subsequent physical, structural, and chemical analysis of battery materials, using techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS).

Battery Performance Testing: Reactors can be used to prepare battery components, such as coating electrode materials. This aids in conducting battery performance tests, including current-voltage curve tests, cycle life tests, to evaluate battery performance and stability.

Research on Novel Battery Technologies: Glass reactors play a role in researching new battery technologies. For example, synthesizing and testing novel battery materials for sodium-ion batteries, manganese-air batteries, solid-state batteries, etc., to evaluate their performance and stability.

Research on the Treatment of Waste Battery Materials: In the field of battery recycling, glass reactors can be used to simulate the treatment of materials from waste batteries, studying effective recycling and reuse methods.

Applications in Materials Science

Synthesis of New Materials: Glass reactors are commonly used to synthesize various new materials, including organic materials, inorganic materials, polymers, etc. Through appropriate reaction conditions and control, researchers can synthesize new materials with specific properties and applications.

Research on Nanomaterials: In the field of nanoscience and nanotechnology, glass reactors are used to synthesize and study nanomaterials, such as nanoparticles, nanotubes, nanosheets, etc. These nanomaterials often exhibit unique physical and chemical properties applicable to various fields, such as electronics, optics, biomedicine.

Synthesis of Ceramic Materials: For the study of ceramic materials, glass reactors can be used to synthesize and sinter ceramic particles, ceramic films, etc. This is essential for understanding the structure, properties, and applications of ceramics.

Preparation of Functional Materials: In materials science, researching functional materials such as sensors, catalysts, optical materials is a common task. Glass reactors provide a suitable environment for the preparation and study of these functional materials.

Coating Material Research: Glass reactors can be used to synthesize various coating materials, such as corrosion-resistant coatings, optical coatings, etc. These coatings are important for improving the durability and optical performance of materials.

Research on Material Modification: By conducting chemical reactions in glass reactors, researchers can achieve surface modification of materials, improving material properties, such as increasing hydrophobicity or enhancing conductivity.

Synthesis of Biomaterials: In biomedical and biomaterials research, glass reactors are used to synthesize biocompatible and biodegradable materials, such as those used for medical implants.

Factors to Consider When Choosing Glass Reactors

Reaction Type: Choose an appropriate glass reactor based on the specific type of reaction. Some reactions may require high-temperature and high-pressure conditions, while others may need cooling systems. Ensure that the reactor can meet the required reaction conditions.

Vessel Material: While the vessel of glass reactors is typically made of glass, different types of glass may have varying chemical resistances. Ensure that the chosen glass material has sufficient resistance to the chemicals used in the experiment.

Volume and Scale: Select the appropriate reactor volume based on the scale of the experiment and the quantity of material to be reacted. Reactors of different volumes are suitable for experiments of varying scales, from small laboratory research to large-scale industrial production.

Heating Method: Consider the heating method and choose a reactor suitable for the experiment’s needs. Some reactors come with external electric heating jackets, while others may require flame or other forms of heating.

Jacket Design: If the experiment requires more precise temperature control or a cooling system, consider choosing a glass reactor with a jacket design. The jacket can be used for fluid circulation to regulate reaction temperature.

Stirring System: If the reaction requires stirring to ensure even mixing, choose a reactor with an appropriate stirring system. Stirring methods may include mechanical stirring, magnetic stirring, etc. Select based on the experiment’s requirements.

Safety: Consider the safety design of the reactor, especially under high-temperature and high-pressure conditions or experiments that may produce harmful gases. Some reactors have explosion-proof designs and other safety features.

Visibility: If the experiment requires real-time observation of the reaction process, ensure that the chosen reactor has good transparency.

Accessories and Attachments: Consider whether accessories and attachments such as temperature probes, flow meters, vacuum connection ports, etc., are needed based on the experiment’s requirements.

Budget: Finally, consider the budget constraints of the laboratory. Choose a reactor that meets experimental needs while staying within the budget limits.

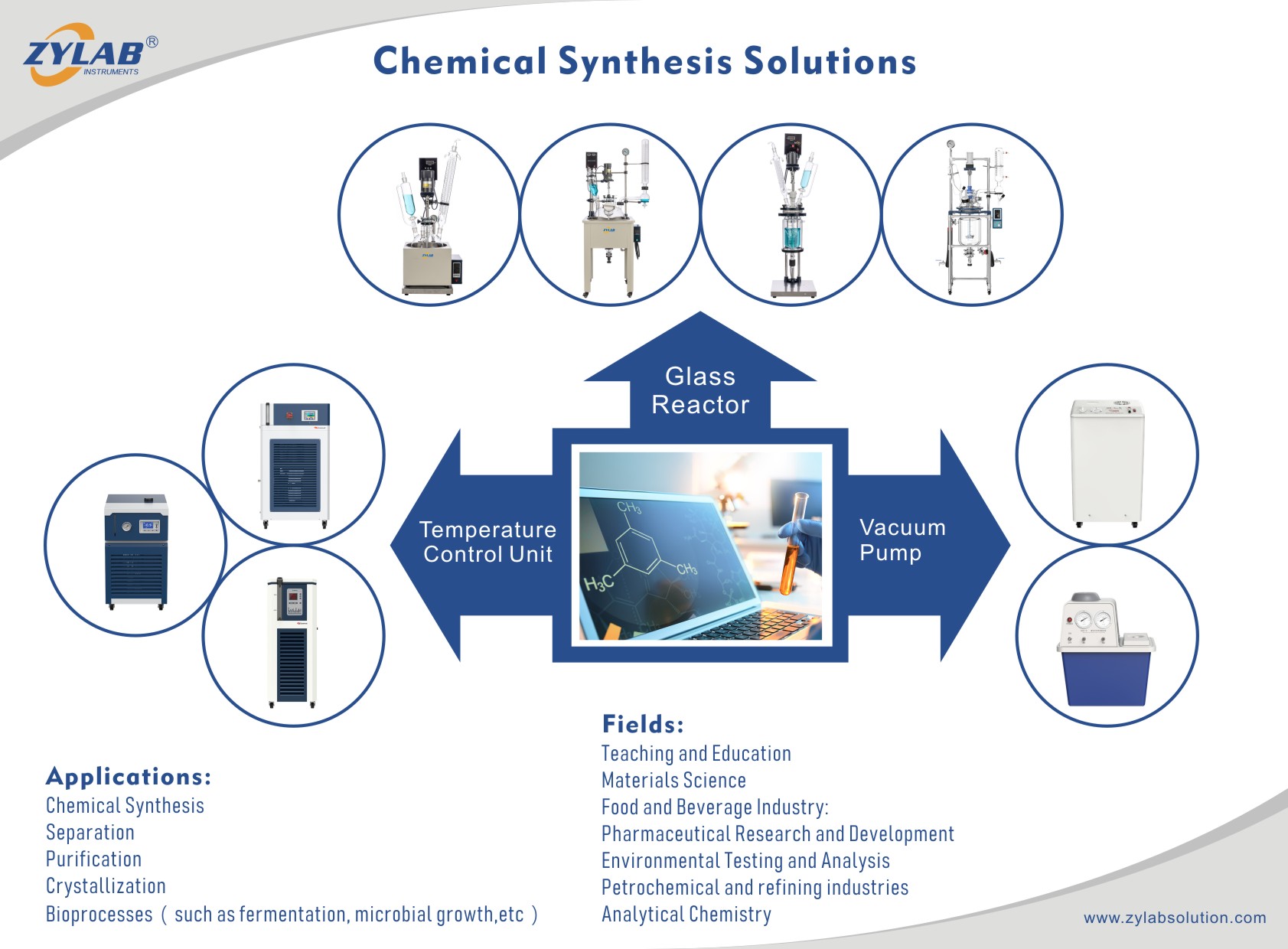

The following are several glass reactors recommended by ZYLAB for your reference:

Choosing the right glass reactor is crucial for the success, safety, controllability, and cost-effectiveness of experiments. This requires careful consideration of experimental requirements and the selection of an appropriate reactor based on experimental conditions and goals.Feel free to contact our technical staff if you have any questions.