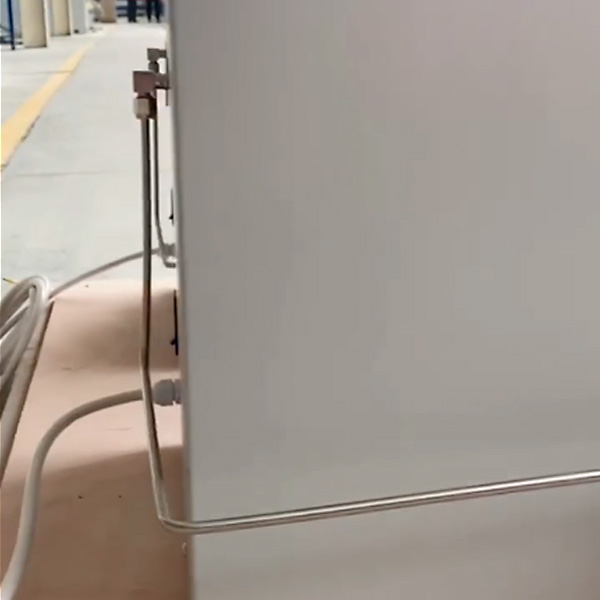

The gas purging system in ZYLAB box furnaces(chamber furnace/muffle furnace) is used to regulate the flow of gases entering and exiting the furnace chamber.

These systems can serve multiple functions depending on the furnace application, such as inert atmospheres, gas flow control, or maintaining specific atmospheres for material processing.

The key components and functions of gas inlet/outlet systems:

Gas Inlet

Purpose: Allows controlled introduction of specific gases into the furnace, such as inert gases (argon, nitrogen), reducing gases (hydrogen), or other reactive gases needed for certain processes (e.g., heat treatment, sintering).

Functionality: The gas inlet connects to the chamber via a valve and can be controlled to regulate gas flow rate and pressure. The inlet also be fitted with a flowmeter to measure gas flow.

Gas Outlet

Purpose: Provides a pathway for gas to exit the furnace chamber.

Functionality: The outlet ensures that excess or unwanted gases can be vented out. This could be especially important if the furnace is operating in a controlled atmosphere where unwanted buildup of gases needs to be removed.

Gas Purging System

Purpose: Purges the furnace chamber with a specific gas (typically nitrogen or argon) before or during processing to remove oxygen or contaminants.

Functionality: Gas purging helps ensure that the furnace atmosphere is stable and free from oxygen or other contaminants, which could interfere with high-temperature processing or material properties. This is often used when working with sensitive materials like metals, ceramics, or semiconductors.

Steps involved in purging:

Pre-purging: Before starting the heating process, the furnace chamber is flushed with the purging gas to remove any residual air or oxygen.

Continuous Purging: A small, continuous flow of gas is maintained during the process to ensure that the atmosphere remains stable.

The flow meters in the gas purging system include options such as float flow meters, single-channel gas mass flow controllers, and multi-channel gas automatic program controllers.

Types of Gas Atmospheres

Inert Atmosphere: Used to prevent oxidation, combustion, or other reactions with oxygen. Common gases used for inert atmospheres include argon (Ar) and nitrogen (N₂).

Reducing Atmosphere: Used to promote reduction reactions in processes like sintering or carburizing. This could involve gases like hydrogen (H₂) or carbon monoxide (CO).

Oxidizing Atmosphere: Less common in furnaces but could be used for specific processes where controlled oxidation is required.

Considerations for Installation

Safety: The gas system should be equipped with proper safety devices, including pressure relief valves and flame arresters, to handle flammable or reactive gases.

Temperature Resistance: The components, such as piping and valves, should be rated for the high temperatures of the furnace.

Contamination Control: Filters and dryers might be used to prevent moisture or particulates from entering the furnace through the gas supply.

Applications for Gas Purging in Box Furnaces

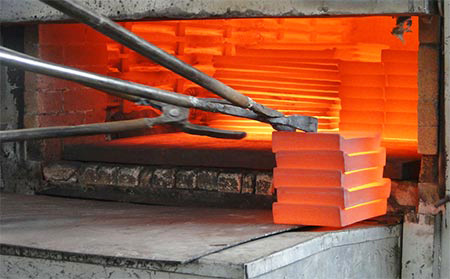

Heat Treatment: Providing an inert or reducing atmosphere during processes like hardening, tempering, or annealing.

Sintering: Maintaining a controlled atmosphere to prevent oxidation or contamination of the material being sintered.

Research and Development: Used in laboratory environments for material processing or experimentation under controlled gas atmospheres.