Table of Contents

In recent years, the laboratory electric furnace has undergone significant developments and improvements. This has resulted in a diverse range of products in the market that cater to the different needs of various industries.

As a leading laboratory electric furnace solutions provider, we have been keeping up with the latest trends and technological advancements.

In this blog post, we will discuss the latest trends and new technologies in laboratory electric furnace development.

Trend 1: Increasing Demand for Energy Efficiency

Energy efficiency is becoming an increasingly important aspect of laboratory electric furnaces. With the rising cost of energy, laboratories are looking for furnaces that can provide high-temperature heating while consuming less energy. To address this demand, manufacturers are developing electric furnaces that are designed to be more energy-efficient.

One of the most notable advancements in energy-efficient electric furnaces is the use of advanced insulation materials.

These materials help to reduce heat loss, which leads to better energy efficiency.Another development is the use of high-precision temperature control systems that help to minimize temperature fluctuations and maintain a stable heating environment.

Zylab furnaces are all manufactured with high purity alumina inorganic refractory(advanced ceramic fibre insulation), overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate. Energy saving 40% and weight lighter about 30% than old furnace.

Trend 2: Integration of Automation and Control Systems

Automation and control systems are becoming increasingly popular in laboratory electric furnaces. These systems help to simplify the operation of the furnace and reduce the risk of human error.

Manufacturers are integrating advanced control systems with laboratory electric furnaces to allow for more accurate temperature control, faster heating, and improved safety.

For example, some electric furnaces now come with touch-screen displays that allow users to set temperature and time parameters easily. These displays also provide real-time information on the status of the furnace, including the temperature and heating time remaining.

Additionally, some electric furnaces are now equipped with safety features such as automatic shut-off systems that activate in case of a malfunction.

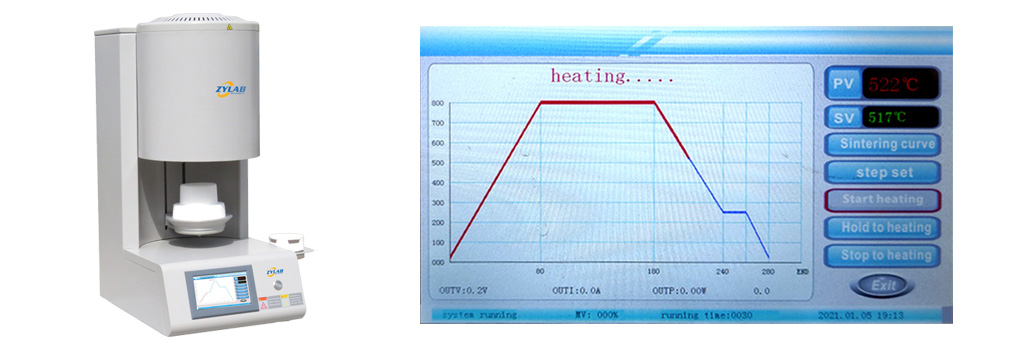

Zylab high-temperature furnaces are all come with a generous, 7” colored graphic touch panel with which the furnace can be controlled and complex heating process can also be programmed. Clear heating curves ; can store temperature curves to avoid the trouble caused by repeated settings of different experimental processes.

And ZYLAB furnaces are all built in protection function, such as for over-heated and broken thermal couple, and leakage.

Trend 3: Adoption of Advanced Heating Technologies

Another trend in laboratory electric furnace development is the adoption of advanced heating technologies. Manufacturers are developing new heating technologies that offer better performance, increased efficiency, and greater temperature control.

One of the most significant advancements in heating technology is the use of induction heating.

Induction heating is a process that uses electromagnetic waves to heat materials. This technology is faster, more efficient, and provides better temperature control than traditional heating methods. Additionally, induction heating is also more environmentally friendly, as it produces fewer emissions and requires less energy.

Trend 4: Increased Focus on Safety and Compliance

Safety and compliance are becoming increasingly important in laboratory electric furnace development. As laboratories become more regulated, manufacturers are developing furnaces that meet strict safety and compliance requirements.

One example of a safety feature in laboratory electric furnaces is the use of automatic shut-off systems.

These systems activate if the furnace detects a malfunction or overheating, reducing the risk of accidents. Additionally, manufacturers are developing furnaces that meet international safety standards and certifications, such as CE and UL.

At ZYLAB, we place great emphasis on quality and safety. Our customers are like our friends and family, and we hope to provide them with the most suitable and absolutely safe products.

ZYLAB furnaces all comply with our national safety standards, and most of them have been CE certified.

Trend 5: Development of Customizable Furnaces

As laboratories become more specialized, manufacturers are developing laboratory electric furnaces that can be customized to meet specific requirements. This allows laboratories to purchase furnaces that are tailored to their needs, rather than settling for a one-size-fits-all solution.

For example, manufacturers are developing furnaces with customizable heating chambers that can accommodate different sample sizes and shapes.

Additionally, some manufacturers offer custom temperature control systems that allow laboratories to set temperature parameters based on their specific requirements.

In conclusion, laboratory electric furnace development is constantly evolving, with manufacturers seeking to provide more energy-efficient, automated, and safe solutions.

The integration of advanced heating technologies and control systems, as well as the development of customizable furnaces, is making it easier for laboratories to perform high-temperature experiments and processes.

As a leading laboratory electric furnace solutions provider, ZYLAB committed to staying up-to-date with the latest trends and technological advancements to meet the evolving needs of our customers, provide our customers with the best possible products and services.

More about the ZYLAB furnaces in detail,check out the post below!

ZYLAB Furnaces and It’s Applications

ZYLAB furnaces are designed with the latest technology and engineering to ensure precision and accuracy in the experiment process.

We are confident that these trends and developments will continue to shape the laboratory electric furnace industry in the coming years, and we are excited to be a part of it.

It is essential for us to stay aware of the latest regulations and standards to ensure that our furnaces meet all safety and compliance requirements. This will not only help us deliver high-quality products but also provide peace of mind to our customers, knowing that they are using safe and compliant equipment in their laboratories!

Share this entry

You might also like