Table of Contents

Introduction

What is a dental Sintering furnace?

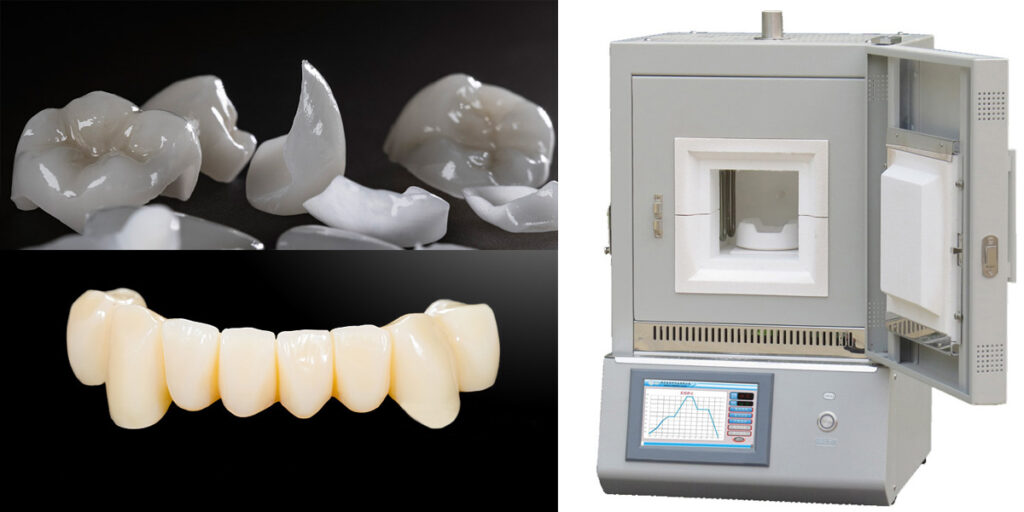

A dental sintering furnace is a specialized piece of equipment used in the dental industry for the process of sintering dental restorations. Sintering is a heat treatment process that involves compacting and forming a powdered material, such as zirconia, into a solid object by applying heat without reaching its melting point.

In dental applications, sintering furnaces are primarily used for the production of ceramic dental restorations, including crowns, bridges, and implant abutments. These restorations are typically made from materials like zirconia, which exhibit excellent biocompatibility and aesthetic properties.

Here’s an overview of how a dental sintering furnace works:

Loading: The dental restoration, which has been pre-manufactured in a “green” or pre-sintered state, is placed inside the sintering furnace.

Heating: The furnace is heated to a specific temperature and held there for a predetermined amount of time. The temperature and time parameters depend on the type of material being sintered and the specific requirements of the dental restoration.

Sintering: During the heating process, the powdered material within the dental restoration starts to fuse together, forming a solid and dense ceramic structure. This consolidation process helps to increase the strength and durability of the dental restoration.

Cooling: After the sintering process is complete, the furnace gradually cools down to room temperature. It’s essential to control the cooling rate to prevent any thermal stress or cracks in the restoration.

Dental sintering furnaces are designed to provide precise temperature control and uniform heating throughout the sintering chamber. They typically utilize advanced heating elements and insulation materials to achieve high temperatures (up to 1500°C or more) and maintain stable thermal conditions.

It’s important to note that dental sintering furnaces are sophisticated equipment and require skilled operators who are familiar with the specific sintering requirements of different dental materials. Additionally, regular maintenance and calibration are necessary to ensure accurate and reliable results.

Applications

What does a dental Sintering furnace do?

Dental sintering furnaces have several applications in the field of dentistry. Here are some common uses:

Dental Restorations: The primary application of dental sintering furnaces is in the fabrication of dental restorations, such as crowns, bridges, and implant abutments. These restorations are typically made from materials like zirconia, which are sintered to achieve the desired strength, fit, and aesthetics.

Prosthetics and Implants: Dental sintering furnaces are also used in the production of prosthetics and dental implant components. These include frameworks for partial dentures, custom abutments, and other implant-supported restorations. Sintering ensures the structural integrity and precision fit of these components.

Orthodontics:In orthodontics, dental sintering furnaces are used for manufacturing orthodontic brackets, wires, and other orthodontic appliances. Sintering allows for the production of strong and durable orthodontic components that can withstand the forces exerted during teeth alignment.

Dental Lab Research and Development: Dental laboratories and research institutions utilize sintering furnaces for developing and testing new dental materials and technologies. The controlled sintering process helps assess the physical and mechanical properties of various dental materials under different conditions.

Dental Education and Training: Dental schools and educational institutions use dental sintering furnaces to teach students about the fabrication and sintering of dental restorations. Students learn how to handle and operate these furnaces as part of their training in dental technology and prosthodontics.

Repair and Remake of Restorations:In some cases, damaged or poorly fitting dental restorations may need repair or remaking. Dental sintering furnaces can be used to remove the existing restoration and sinter a new one, ensuring proper fit and function.

Dental sintering furnaces play a crucial role in the manufacturing process of various dental components, providing precise control over the sintering parameters to achieve high-quality and durable restorations.

Benefit

The use of dental sintering furnaces in the dental industry offers several benefits, including:

1. High Precision: Dental sintering furnaces provide precise temperature control and uniform heating, ensuring consistent and accurate sintering of dental restorations. This results in restorations with precise dimensions, excellent fit, and minimal distortion.

2. Enhanced Strength and Durability:Sintering helps to increase the strength and durability of dental restorations by promoting the fusion of powdered materials into a solid ceramic structure. This ensures that the restorations can withstand the forces exerted during normal oral functions, such as biting and chewing.

3. Aesthetics: Dental sintering furnaces are often used for sintering tooth-colored materials like zirconia, which offer excellent aesthetics. The sintering process helps achieve the desired shade, translucency, and natural appearance of the dental restorations, enhancing the overall esthetics of the patient’s smile.

4. Biocompatibility: Dental restorations made using sintering furnaces are typically fabricated from biocompatible materials like zirconia. These materials have been extensively tested and proven to be safe for use in the oral environment, minimizing the risk of adverse reactions or allergies.

5. Time Efficiency: Sintering furnaces are designed to heat up and cool down at optimal rates, reducing the overall processing time. This allows for quicker fabrication of dental restorations, which can be especially beneficial in busy dental laboratories or clinics where fast turnaround times are required.

6. Customization and Versatility: Dental sintering furnaces enable the fabrication of highly customized dental restorations. They can be used with a variety of materials and offer flexibility in terms of design, allowing for the creation of restorations that meet the specific needs and preferences of individual patients.

7. Research and Development: Dental sintering furnaces are valuable tools for research and development purposes. They facilitate the testing and refinement of new dental materials and technologies, contributing to advancements in the field of dentistry and improving the quality of dental restorations.

Overall, the use of dental sintering furnaces helps dental professionals achieve superior restorative outcomes, providing patients with durable, esthetic, and well-fitting dental restorations that contribute to their oral health and overall well-being.

Dental Sintering Furnace Price

The price of a dental sintering furnace can vary depending on various factors such as the brand, model, features, and additional accessories included.

Generally, dental sintering furnaces can range in price from a few thousand dollars to tens of thousands of dollars. Entry-level or basic models may be available in the lower price range, while high-end models with advanced features and capabilities can be more expensive.

It is recommended to contact us immediately to get the most accurate and up-to-date pricing information for the specific dental sintering furnace you are interested in. We can provide you with detailed information on pricing and any available options or packages that suit your requirements.

What to consider when purchasing dental Sintering furnace?

When purchasing a dental sintering furnace, there are several important factors to consider. Here are some key points to keep in mind:

Sintering Technology: Different furnaces may use different sintering technologies, such as conventional sintering or microwave sintering. Each technology has its advantages and considerations, so it’s essential to understand the pros and cons of each and choose the one that aligns with your specific needs.

Temperature and Heating Capacity: Consider the maximum temperature the furnace can reach and whether it meets the requirements for sintering the materials you work with. Also, check the heating capacity and the size/volume of the furnace chamber to ensure it can accommodate your workload.

Programmability and Controls: Look for a furnace that offers programmable settings and precise controls. The ability to set and control the sintering parameters, such as temperature ramp-up and dwell times, is important for achieving optimal results. User-friendly interfaces and intuitive controls can make operation easier.

Compatibility: Ensure that the furnace is compatible with the materials and dental restorations you commonly work with. Different furnaces may be designed for specific types of materials or restorations, so check the manufacturer’s recommendations and specifications.

Safety Features: Consider the safety features provided by the furnace, such as over-temperature protection, insulation, and ventilation systems. Safety should be a priority to protect both the operator and the equipment.

Maintenance and Support: Check the maintenance requirements of the furnace and inquire about the availability of technical support, warranty, and after-sales service. It’s important to have reliable support in case of any issues or questions that may arise during the furnace’s lifespan.

Price and Budget: Determine your budget and consider the value for money offered by different furnace models. Compare prices from different suppliers and consider the long-term costs, including maintenance, consumables, and potential upgrades.

User Reviews and Recommendations: Read reviews and seek recommendations from other dental professionals or colleagues who have experience with the specific furnace models you are considering. Their insights can provide valuable information about the performance, reliability, and user experience.

By carefully considering these factors, you can make an informed decision and choose a dental sintering furnace that meets your specific requirements and offers the best value for your investment.

FAQ

Q1: What materials can be sintered using a dental sintering furnace?

A1: Dental sintering furnaces are primarily used for sintering materials like zirconia, which is a popular choice for dental restorations due to its biocompatibility and aesthetic properties. Other materials that can be sintered include alumina, lithium disilicate, and certain types of ceramics specifically formulated for dental applications.

Q2: How long does the sintering process take in a dental sintering furnace?

A2: The duration of the sintering process can vary depending on factors such as the type of material being sintered and the specific requirements of the dental restoration. Typically, sintering cycles can range from a few hours to several hours.

Q3: Are dental sintering furnaces safe to use?

A3: Yes, dental sintering furnaces are designed with safety features to ensure the well-being of operators and patients. They are equipped with temperature controls, insulation, and ventilation systems to prevent overheating and release of harmful gases. However, it’s important to follow proper safety protocols, such as wearing appropriate protective gear and operating the furnace according to the user guidelines.

Q4: Can dental restorations made using a sintering furnace be repaired?

A4: In some cases, dental restorations made using a sintering furnace can be repaired. However, the repair process can vary depending on the type and extent of damage. Minor repairs such as small cracks or chips may be fixable, while extensive damage may require the replacement of the restoration. It’s best to consult a dental professional for an assessment and appropriate repair options.

Q5: How should I maintain a dental sintering furnace?

A5: Proper maintenance is crucial to ensure the performance and longevity of a dental sintering furnace. Regular cleaning of the furnace chamber, calibration of temperature controls, and inspection of heating elements are important maintenance tasks. It’s recommended to follow the user guidelines for maintenance procedures and schedule periodic servicing by qualified technicians.

Q6: Can a dental sintering furnace be used in a dental clinic or is it primarily for dental laboratories?

A6: Dental sintering furnaces are commonly used in dental laboratories for the fabrication of dental restorations. They require specialized equipment and skilled operators for optimal use. While it is possible to have a sintering furnace in a dental clinic, it is less common due to the technical requirements and space considerations. Dental clinics often send their cases to dental laboratories equipped with sintering furnaces for the fabrication of restorations.

Precautions and maintenance

Important precautions tips for dental sintering furnaces:

1. Read and follow the manufacturer’s instructions and guidelines for operating the sintering furnace.

2. Ensure that the furnace is placed on a stable and heat-resistant surface to prevent accidents or damage.

3. Use appropriate personal protective equipment, such as heat-resistant gloves and safety glasses, when handling the furnace and hot components.

4. Avoid opening the furnace door while it is in operation to prevent heat loss and potential injury from hot surfaces.

5. Do not exceed the recommended maximum temperature or heating rate specified by the manufacturer to avoid damaging the furnace or compromising the quality of the sintered restorations.

6. Properly ventilate the sintering area to remove any potentially harmful gases or fumes emitted during the sintering process.

Maintenance tips for dental sintering furnaces:

1. Regularly clean the sintering chamber and remove any debris or residual materials that may interfere with the sintering process.

2. Follow the manufacturer’s recommendations for calibration and periodic maintenance of temperature controls and sensors to ensure accurate temperature readings.

3. Inspect the heating elements and insulation materials regularly for signs of wear or damage. Replace any faulty components promptly to maintain proper heating performance.

4. Keep the furnace’s electrical connections clean and free from dust or debris that may affect its operation.

5. Store and handle the sintering furnace with care to avoid physical damage, such as impacts or excessive vibration.

6. Schedule regular servicing and inspections by qualified technicians to identify and address any potential issues before they escalate.

Remember, it is essential to consult the specific guidelines provided by the manufacturer of your dental sintering furnace for detailed instructions on precautions, maintenance, and safe operation.

Share this entry

You might also like