Table of Contents

Introduction

What is a dental ceramic furnace?

A dental ceramic furnace, also known as a dental porcelain furnace or dental firing furnace, is a specialized piece of equipment used in the dental industry for the firing or crystallization of dental ceramic materials. These furnaces are specifically designed to heat and process dental ceramics to achieve the desired properties and aesthetics necessary for dental restorations.

Here are some key points about dental ceramic furnaces:

Purpose: Dental ceramic furnaces are used for firing dental ceramic materials, such as porcelain, to transform them into a solid and durable state suitable for dental restorations. The firing process involves heating the ceramic at specific temperatures to achieve proper crystallization and bonding.

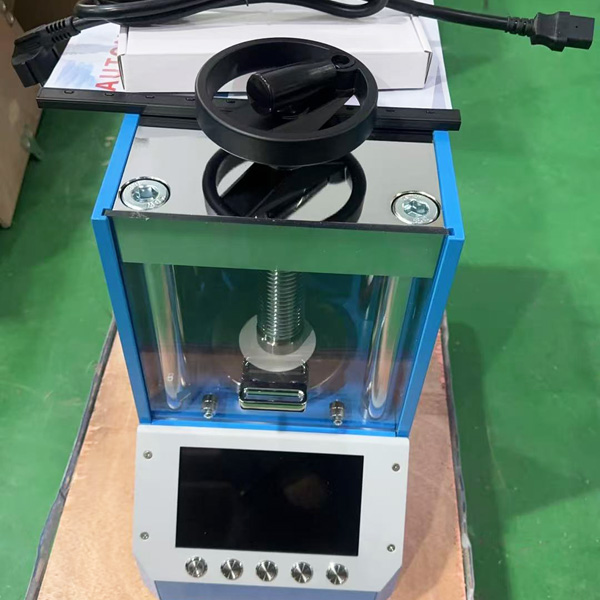

Types of Furnaces: There are various types of dental ceramic furnaces available, including conventional ceramic furnaces, high-temperature ceramic furnaces, and programmable furnaces. Conventional furnaces typically rely on manual control and observation, while programmable furnaces offer advanced features such as precise temperature control and programmable firing cycles.

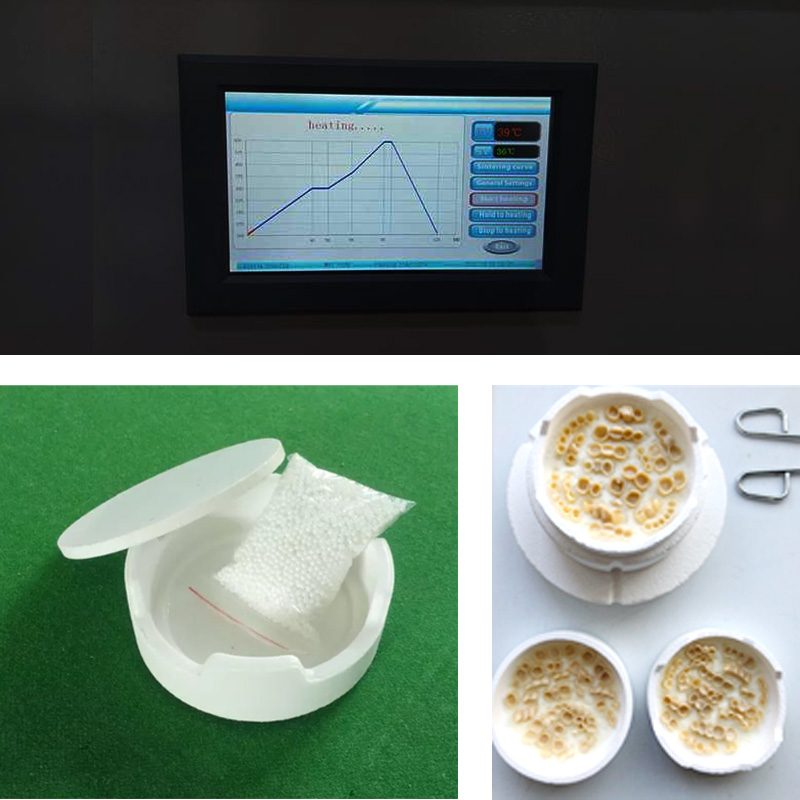

Firing Cycle: The firing cycle in a dental ceramic furnace consists of several stages, including pre-drying, heating, and cooling. The specific temperature and time parameters for each stage depend on the type of ceramic material being fired and the desired properties of the final restoration.

Temperature Control: Dental ceramic furnaces provide accurate temperature control to ensure consistent and reliable firing results. They are equipped with heating elements and sensors that monitor and regulate the temperature throughout the firing process.

Safety Features: Dental ceramic furnaces include safety features to protect both the operator and the equipment. These features may include thermal insulation to prevent heat loss and minimize external surface temperatures, as well as safety interlocks to prevent accidental opening of the furnace during operation.

Maintenance: Regular maintenance is essential to keep the dental ceramic furnace in optimal condition. This includes cleaning the firing chamber, inspecting and replacing heating elements as needed, and calibrating temperature controls to ensure accurate readings.

Dental ceramic furnaces play a critical role in the fabrication of dental restorations, allowing for the customization and creation of natural-looking, durable, and aesthetically pleasing dental ceramics used in crowns, veneers, inlays, and other dental prosthetics.

Applications

What does a porcelain furnace do?

Dental ceramic furnaces have several applications in the field of dentistry. Here are some common uses:

1. Dental Crown and Bridge Fabrication: Dental ceramic furnaces are extensively used in the fabrication of dental crowns and bridges. These restorations are typically made from ceramic materials that are fired in the furnace to achieve the desired strength, fit, and aesthetic appearance.

2. Veneer Production: Dental veneers, which are thin shells of ceramic material used to enhance the appearance of front teeth, are often fabricated using dental ceramic furnaces. The firing process in the furnace helps create veneers with the desired translucency and color properties for a natural-looking smile.

3. Inlays and Onlays: Dental ceramic furnaces are employed in the production of inlays and onlays, which are indirect restorations used to restore damaged or decayed teeth. The furnace ensures that the ceramic material used for these restorations is properly fired, resulting in restorations that fit precisely and provide long-lasting durability.

4. Implant Prosthetics: Dental ceramic furnaces play a vital role in the fabrication of ceramic components for dental implants. These components, such as implant abutments and implant-supported crowns, are fired in the furnace to achieve the necessary strength and aesthetics for successful implant restorations.

5. Orthodontic Appliances: Dental ceramic furnaces are also utilized in the production of orthodontic appliances, such as ceramic brackets. These appliances are fired in the furnace to ensure that they are strong and durable enough to withstand the forces exerted during orthodontic treatment.

6. Dental Laboratory Research and Development: Dental ceramic furnaces are used in dental laboratories for research and development purposes. They enable testing and refinement of new ceramic materials, firing techniques, and restoration designs to improve the quality and performance of dental restorations.

Dental ceramic furnaces are integral to the production of high-quality and aesthetically pleasing dental restorations. Their versatility and precise firing capabilities make them essential tools in dental laboratories and clinics for a wide range of applications in restorative and cosmetic dentistry.

Benefit

The use of dental ceramic furnaces in the dental industry offers several benefits:

1. Customization and Aesthetics: Dental ceramic furnaces allow for the customization of dental restorations by providing precise control over the firing process. This enables dental technicians to achieve the desired shade, translucency, and natural appearance of the ceramic restorations, resulting in aesthetically pleasing outcomes that blend seamlessly with natural teeth.

2. Strength and Durability: Firing dental ceramics in specialized furnaces helps enhance the strength and durability of the restorations. The controlled heating and cooling process promotes proper crystallization and bonding of the ceramic material, resulting in strong and long-lasting dental restorations that can withstand the forces of normal oral function.

3. Biocompatibility: Dental ceramic materials used in these furnaces are biocompatible, meaning they are well-tolerated by the oral tissues and have minimal risk of adverse reactions or allergies in patients. This ensures the restorations are safe and compatible with the oral environment.

4. Precise Firing Control: Dental ceramic furnaces provide precise temperature control throughout the firing process. This level of control allows for consistency and repeatability in achieving the desired physical properties of the ceramic material, such as hardness, density, and shrinkage, resulting in reliable and predictable outcomes.

5. Time Efficiency: Modern dental ceramic furnaces offer fast heating and cooling rates, reducing the overall processing time for dental restorations. This can be especially beneficial in dental laboratories where fast turnaround times are required, enabling efficient production and delivery of restorations to dental offices.

6. Versatility: Dental ceramic furnaces are versatile and can accommodate a wide range of ceramic materials used in dental restorations, including porcelain, zirconia, and lithium disilicate. This versatility allows dental technicians to work with different materials and select the most suitable option for each patient’s specific needs.

7. Research and Development: Dental ceramic furnaces play a crucial role in research and development activities in the dental field. They facilitate the testing and refinement of new ceramic materials, firing techniques, and restoration designs, contributing to advancements in dental technology and improving the quality of dental restorations.

Overall, dental ceramic furnaces provide dental professionals with the tools and capabilities to create durable, natural-looking, and patient-specific dental restorations that meet functional and aesthetic requirements.

Dental Ceramic Furnace Price

The price of a dental ceramic furnace can vary significantly based on several factors, including the brand, model, specifications, features, and the supplier or distributor. Additionally, the price may also depend on the country or region where the furnace is being purchased.

Generally, dental ceramic furnaces can range in price from a few thousand dollars to tens of thousands of dollars. Higher-end furnaces with advanced features and larger capacities tend to be more expensive.

If you are interested in purchasing a dental ceramic furnace, we recommend contacting us directly to inquire about the price. We can provide detailed information and a free quote based on your specific requirements.

What to consider when purchasing dental ceramic furnace?

When purchasing a dental ceramic furnace, there are several important factors to consider to ensure you select the right equipment for your needs. Here are some key considerations:

1. Temperature range: Dental ceramic furnaces should be capable of reaching high temperatures required for firing dental ceramics. Check the temperature range of the furnace and ensure it covers the temperature requirements for the specific types of ceramics you work with.

2. Heating technology: Different dental ceramic furnaces may use various heating technologies, such as electric resistance heating or induction heating. Each technology has its own advantages and considerations, so research and understand the benefits and limitations of each before making a choice.

3. Firing programs and control: Look for a furnace that offers programmable firing cycles and precise temperature control. Dental ceramics often require specific firing profiles, and having the ability to program and control these parameters allows for consistent and accurate results.

4. Chamber size and capacity: Consider the size of the furnace chamber and whether it can accommodate the quantity and size of dental restorations you typically work with. Ensure the furnace has enough space to hold the necessary ceramic materials without overcrowding, which could affect firing quality.

5. Energy efficiency: Look for furnaces that are designed with energy efficiency in mind. Energy-efficient furnaces can help reduce operating costs and minimize environmental impact.

6. Safety features: Check for safety features such as automatic shut-off, alarms, and ventilation systems to ensure a safe working environment. These features can help prevent accidents and ensure proper ventilation of fumes and gases generated during firing.

7. Ease of use and maintenance: Consider the user-friendliness of the furnace, including the control interface and programming options. Additionally, assess the maintenance requirements of the furnace, such as cleaning procedures and replacement parts availability.

8. Reputation and support: Research the manufacturer’s reputation and customer reviews to gauge the reliability and quality of their dental ceramic furnaces. Consider the availability of technical support, warranty coverage, and after-sales service.

9. Budget: Determine your budget range and compare the features and capabilities of different furnaces within that range. While it’s important to consider cost, prioritize the features and quality that align with your specific needs and long-term goals.

10. Compliance and certifications: Ensure that the dental ceramic furnace meets relevant safety and regulatory standards, such as those set by dental associations or government agencies. Look for certifications or approvals that indicate compliance with industry standards.

By considering these factors, you can make an informed decision when purchasing a dental ceramic furnace that best suits your requirements and provides reliable performance for your dental laboratory or practice.

FAQ

Q: How does a dental ceramic furnace work?

A: Dental ceramic furnaces work by subjecting ceramic materials to controlled heating and cooling cycles. The furnace is programmed with specific temperature profiles and firing schedules tailored to the type of ceramic material being used. The ceramic restorations or components are placed inside the furnace, and the temperature is gradually increased to reach the desired firing temperature. The material is held at that temperature for a specific duration to allow for proper crystallization and bonding. After the firing process, the furnace cools down gradually to prevent stress or cracking in the ceramic restorations.

Q: What types of ceramic materials can be fired in a dental ceramic furnace?

A: Dental ceramic furnaces are designed to fire various types of ceramic materials used in dentistry, including dental porcelain, zirconia, lithium disilicate, and feldspathic ceramics. Each material has specific firing requirements and temperature ranges, and the furnace’s programming and settings can be adjusted accordingly.

Q: How long does the firing process take in a dental ceramic furnace?

A: The duration of the firing process in a dental ceramic furnace can vary depending on factors such as the type of ceramic material, the thickness of the restoration, and the specific firing parameters. Generally, the firing process can take several hours, with additional time for cooling. It’s important to follow the manufacturer’s instructions and recommendations for the specific material being used.

Q: Can a dental ceramic furnace be used for multiple restorations simultaneously?

A: Yes, dental ceramic furnaces are designed to accommodate multiple restorations simultaneously. However, it’s important to ensure that the restorations are properly spaced and positioned to allow for even heat distribution and prevent contact or interference between them during firing.

Q: How should I maintain a dental ceramic furnace?

A: Regular maintenance is important to ensure the optimal performance and longevity of a dental ceramic furnace. This includes routine cleaning of the firing chamber, inspection and replacement of heating elements or thermocouples as needed, calibration of temperature controls, and adherence to any specific maintenance procedures recommended by the manufacturer. It’s also crucial to follow the manufacturer’s guidelines for any necessary safety checks or servicing.

Q: Can a dental ceramic furnace be used in a dental clinic or is it primarily for dental laboratories?

A: Dental ceramic furnaces are primarily used in dental laboratories where there is a need for more advanced ceramic processing. The complexity and precision of the firing process, as well as the expertise required for handling and programming the furnace, make it less common in dental clinics. Dental clinics often send cases to dental laboratories equipped with ceramic furnaces for the fabrication of restorations.

Share this entry

You might also like