As a laboratory electric furnace solutions provider, we are committed to offering top-quality products with advanced features to meet our customers’ needs. In this blog post, we will outline some of the key Characteristics of ZYLAB Furnaces.

ZYLAB Furnaces Highlight

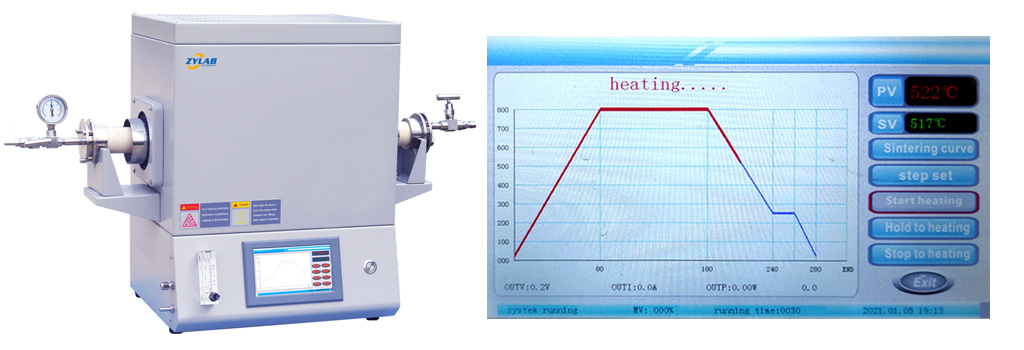

1. Have a generous 7” colored graphic touch panel with which the furnace can be controlled and complex heating process can also be programmed. Clear heating curves ; can store temperature curves to avoid the trouble caused by repeated settings of different experimental processes.

2. Advanced ceramic fibre furnace chamber, to ensure a fast heating rate, and save power, more energy-efficient.

3. Safety Features:

built in protection function, such as for over-heated and broken thermalcouple, over-current and leakage.

4. Easy to Use:

ZYLAB furnaces are easy to operate and maintain, with clear instructions for setup and use.

5. Versatile:

ZYLAB furnaces can be used for a variety of applications, including ashing, calcining, sintering, and annealing, etc.

Read our post about more applications of ZYLAB furnaces:

ZYLAB Furnaces and It’s Applications

ZYLAB furnaces are designed with the latest technology and engineering to ensure precision and accuracy in the experiment process.

If you have any questions during the furnace experiment, contact us immediately and we will be very pleased to help!

ZYLAB Furnaces Detail Characteristics

1. The first-class workmanship and using high-quality materials.

2. The exquisite design gives people a smooth experience.

3. Max. Temperature up to 1700°C, making them ideal for applications requiring high-temperature conditions.

4. Intelligent 7” color touch screen temperature controller, easy to operate, 30 segments programmable and auto control for accurate temperature control.

5. The sintering curve that changes with temperature makes you clear at a glance and solves the problem of wrong curve setting.

6. 15 sintering curves can be pre-stored to save the trouble of repeated modification, plus the classic style and touch screen graphic interface, making the operation of the device more simple.

7. Reasonable heat dissipation design scheme, double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Manufactured with high purity alumina inorganic refractory(advanced ceramic fibre insulation), overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate. (Energy saving 40% and weight lighter about 30% than old furnace.)

9. By using special lining import from Japan and top quality heating element with excellent acid and corrosion resistance, products are protected against chemical contamination at the best and long service life.

10. Vent hole carefully designed is the perfect solution to the waste gas during material sintering.

ZYLAB Furnaces, come with low power consumable, exquisite structure and light weight, are the ideal electric furnaces for material research labs, scientific research and various institutes, also widely used in the dental field for burnout, sintering.