Table of Contents

Introduction

What is a Ceramic Kiln?

Ceramic kilns are furnaces used to fire (heat) ceramic materials at high temperatures, transforming them into hardened, durable forms.

These kilns are specifically designed to meet the unique requirements of ceramic materials, providing precise temperature control and controllable atmospheres to achieve optimal ceramic processing.

Our ceramic kilns are widely used in ceramic arts education, ceramic hobbyist activities, research and development, and are essential tools in pottery and ceramic arts.

Workflow

Loading

Place the ceramic pieces to be processed into the kiln chamber. These pieces may include pottery, ceramic crafts, or other ceramic products made from clay.

Preheating

Preheating is typically done before the actual firing process to remove any residual moisture from the ceramics, thus preventing cracking or fracturing at high temperatures.

Firing

Once preheating is complete, the kiln gradually heats up to the desired firing temperature. This temperature depends on the type of ceramic material and the desired firing effect. The firing process usually involves different stages, such as bisque firing and main firing. During firing, ceramic pieces undergo chemical and physical changes until they reach the desired level of hardness.

Cooling

After firing is complete, the kiln gradually cools down to a safe temperature.

Unloading

Once the kiln has fully cooled, the finished ceramic pieces can be removed. They are now hardened and durable, ready for further decoration, glazing, or other finishing processes.

Applications

What are the application areas of ceramic kilns?

Ceramic Art

Ceramic kilns are essential tools for ceramic artists and craftsmen in creating various ceramic works such as pottery, ceramic sculptures, and decorative pieces.

Ceramic Industry

Ceramic kilns play a crucial role in the ceramic manufacturing industry. They are used in the production of various ceramic products including porcelain, ceramic tiles, and ceramic pipes.

Ceramic Education

Ceramic kilns are widely utilized in educational institutions and studios for teaching and training in ceramic techniques. Students can learn the ceramic making process and practice firing their own creations using ceramic kilns.

Ceramic Research and Development

In the field of ceramic material research and development, ceramic kilns are employed to test the firing effects of different material formulations and to explore new ceramic production techniques and processes.

Ceramic Restoration and Conservation

In the field of cultural heritage conservation, ceramic kilns can be used for the restoration of ancient ceramic artifacts or for protective firing to extend their lifespan while preserving their original appearance.

The application of ceramic kilns in pottery studios

Firing pottery and ceramic pieces

Ceramic kilns are essential equipment used for firing pottery, ceramic sculptures, decorations, and other ceramic works.

Teaching and training

Many pottery studios offer pottery courses and workshops, where kilns are used to teach and train students in pottery making skills.

Artistic creation space

Ceramic kilns provide a space for artistic creation, allowing ceramic artists to experiment and create. Artists in the studio can share kiln resources, inspire each other, and collaborate to create more interesting works.

Customization and batch production

Pottery studios can use kilns for customization and batch production to meet customer demands.

Community and event venues

Pottery studios often serve as gathering places for pottery enthusiasts, where kilns are not only creative tools but also important facilities for community activities. Studios can host various pottery events and exhibitions, attracting more people to participate and experience the joy of pottery.

Advantages of Ceramic Kilns

1、Lightweight with Large Space (Available in sizes from 0.014m³ to 0.07m³). Equipped with swivel casters for easy mobility.

2、Three-dimensional cycle firing in all directions,the heating is balanced, the firing is more stable.

3、A variety of firing modes to meet diverse needs, whether it is on-glaze underglaze, glaze firing (color glaze, artistic glaze, crack glaze), green body drying, ceramic firing, blue and white firing, etc.

4、Split controller has a longer service life.

5、Intelligent APP control, it can be controlled remotely and controlled by one key.

6、Green and environmental protection, low energy consumption and more energy-saving, long-term use is more cost-effective.

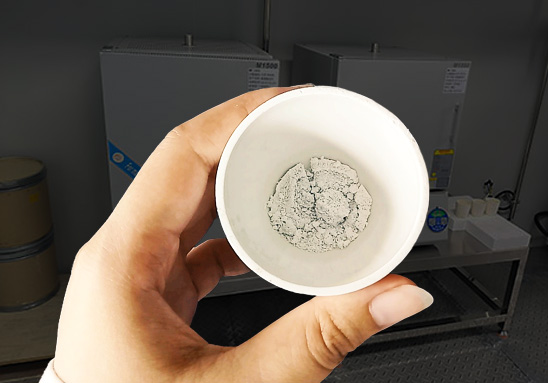

Images for Ceramic Kiln

Ceramic Kiln Price

The price of ceramic kilns can vary widely depending on factors such as size, capacity, brand, features, and whether it’s new or used.

Generally, smaller kilns suitable for hobbyists or small studios can range from a few hundred to a few thousand dollars.

Larger, industrial-grade kilns used for professional ceramic production can cost several thousand to tens of thousands of dollars.

For a more specific and up-to-date price range, it’s best to check with ceramic kiln suppliers directly, either through their websites or by contacting them directly for a quote.

What to Consider When Purchasing Ceramic Kiln?

When purchasing a ceramic kiln, there are several important factors to consider to ensure that you choose the right one for your needs:

Size and Capacity

Consider the size of the kiln you need, based on the volume of ceramics you plan to fire.

Temperature Range

Check the maximum temperature capability of the kiln to ensure it meets the firing requirements of the clay and glazes you’ll be using.

Temperature Control

Look for kilns with precise temperature control features, such as digital controllers or programmable settings, to achieve consistent and accurate firing results.

Even Heating

Ensure that the kiln provides even heating throughout the firing chamber to prevent uneven firing, cracking, or warping of ceramics.

Construction and Insulation

Consider the construction materials and insulation of the kiln, as these factors can affect heat retention, energy efficiency, and durability.

Ventilation

Check if the kiln has adequate ventilation systems to remove fumes and gases generated during firing, ensuring a safe working environment.

Ease of Use

Look for kilns with user-friendly features such as easy-to-read controls, convenient loading and unloading mechanisms, and safety features.

Budget

Determine your budget and compare prices from different suppliers to find a kiln that offers the best value for your investment.

Warranty and Support

Consider the warranty coverage and after-sales support offered by the manufacturer or supplier, including technical assistance, maintenance services, and replacement parts availability.

FAQ

Q: How can I extend the lifespan of the kiln?

A: Regularly clean the kiln chamber, check the connections at the back cover for looseness, ensure stable voltage during normal firing processes, operate the kiln door within the correct temperature range, and recommend firing temperature between 1200-1280 degrees Celsius.

Q: How much electricity does each kiln consume? How do I calculate it?

A: One kilowatt-hour (kWh) is consumed for every hour of firing. Generally, firing times are 8-10 hours, so it would be approximately 64-80 kWh. However, in practical scenarios, kilns heat up gradually during firing, so the actual electricity consumption may be slightly lower. Based on experience, it typically requires about 50 kWh per firing for a kiln with a chamber volume of 0.07m³.

Q: What aspects should be considered in evaluating the quality of a kiln?

A: To judge the quality of a kiln, firstly, look for kilns from reputable manufacturers with good brand reputation and market feedback. Secondly, assess the material quality and craftsmanship of the kiln itself. Additionally, the manufacturer’s after-sales service capability is also crucial.