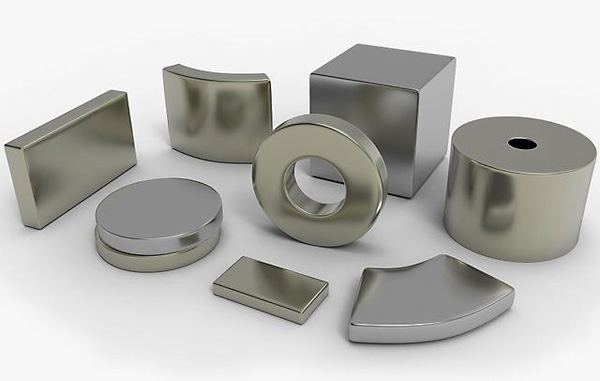

Sintered NdFeB permanent magnets are produced using the powder metallurgy method, involving five main stages: raw material preparation, crushing and powdering, orientation and forming, sintering and heat treatment, and machining.

Category Archives: Thermal Processing

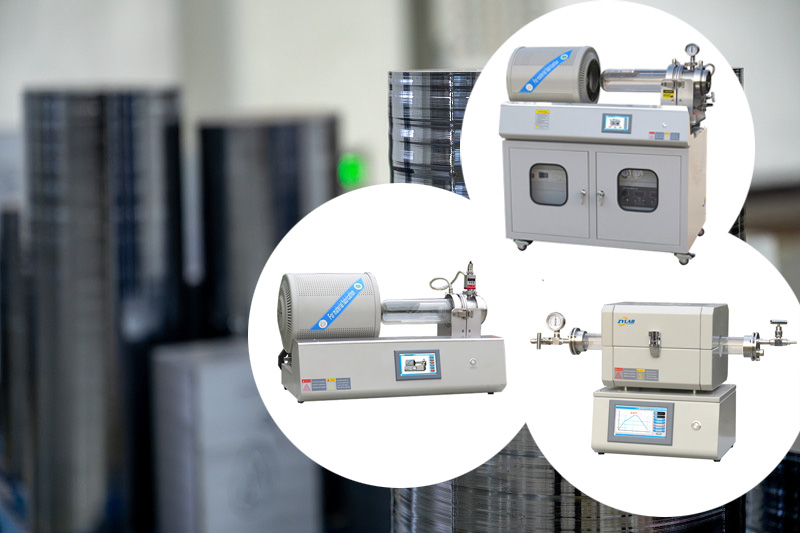

According to the requirements of different processes, equipment such as tube furnaces, heat treatment furnaces, and CVD systems must meet varying demands for temperature accuracy and uniformity.

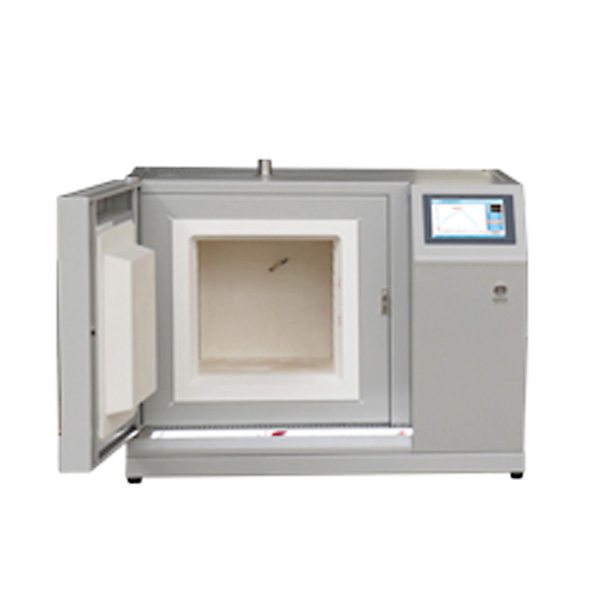

For detailed operating instructions for the muffle furnace, please contact ZYLAB technical staff to request the relevant materials.

A calcination furnace is a specialized industrial device used for the calcination process, primarily designed to thermally treat materials at high temperatures to induce physical or chemical changes.

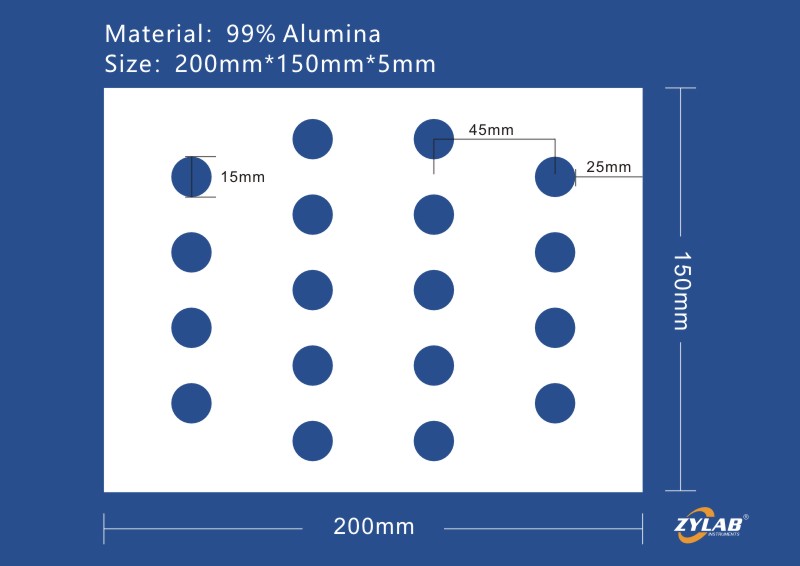

Customized alumina kiln furniture refers to functional components designed and manufactured to meet specific high-temperature processing requirements or equipment needs. Widely used in industrial kilns and laboratory high-temperature equipment, they serve roles such as support, load-bearing, or insulation.

These systems can serve multiple functions depending on the furnace application, such as inert atmospheres, gas flow control, or maintaining specific atmospheres for material processing.

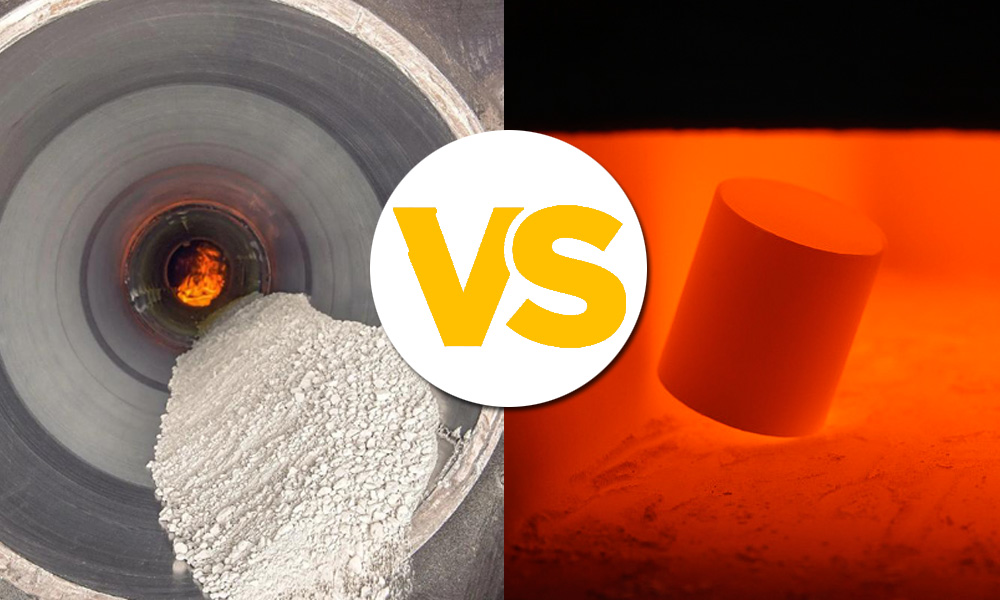

Calcination (Calcination) and sintering (Sintering) are two common high-temperature processes. Although both involve heating, their purposes, temperatures, processes, and results differ significantly.

A laboratory inert gas preheater is a specially designed device used to heat inert gases, such as argon, nitrogen, or helium. It rapidly raises the temperature of the inert gas to the required level before it enters the experimental apparatus, meeting the specific temperature demands of certain experiments or processes.

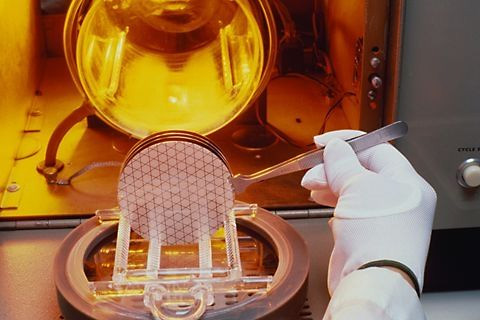

The primary purpose of annealing is to improve the crystal quality of monocrystalline silicon, relieve internal stress, repair defects, and optimize its physical and electronic properties, thereby meeting the application requirements in the semiconductor and photovoltaic fields.

Crystalline hydrogen reduction is a technique that uses hydrogen as a reducing agent to process crystalline materials. It is commonly employed to modify the chemical properties of materials, enhance their physical performance, or achieve specific functionalization.