The ZYLAB 1200°C Large Diameter Tube Furnace is an essential tool for cutting-edge carbon material research and industrial-scale production. By providing high-temperature uniformity, precise control, and a large processing capacity, it enables researchers and manufacturers to develop high-performance carbon materials efficiently.

Category Archives: Thermal Processing

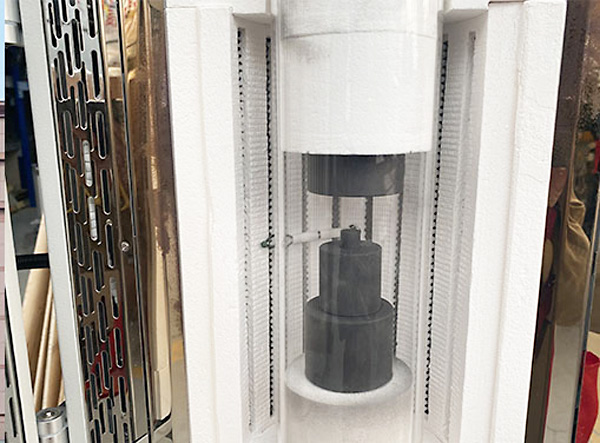

The 1200°C Vacuum Hot Press Furnace is a powerful tool for both metal powder densification and ceramic material sintering. Its ability to operate under high pressure and in a controlled vacuum environment allows for precise material treatment, leading to enhanced material properties and reduced defects.

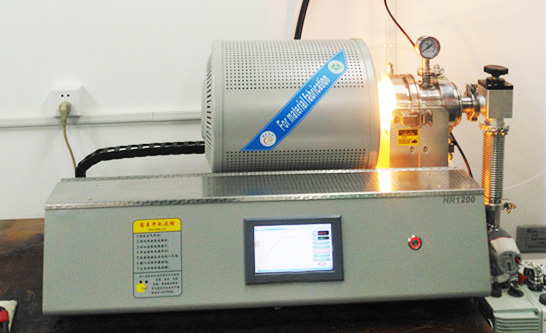

In material science research, precise temperature and atmospheric control are crucial for developing materials with enhanced properties. A university’s materials science department recently integrated a 1700℃ vacuum atmosphere furnace into their research facilities, significantly advancing new ceramic material development and metal heat treatment studies.

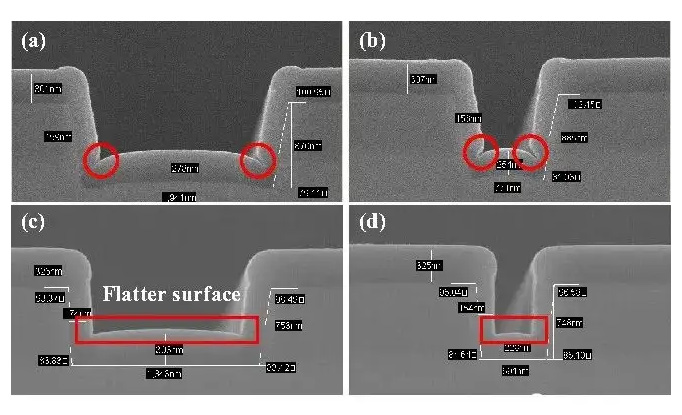

CVD (Chemical Vapor Deposition) offers superior step coverage compared to PVD (Physical Vapor Deposition) due to differences in their deposition mechanisms and physical properties.

The choice between CVD and PVD depends on specific application requirements and material properties.

The temperature of a tube furnace varies depending on its design, materials, and intended application. From low-temperature research to ultra-high-temperature industrial processes, these furnaces play a pivotal role in advancing technology and innovation.

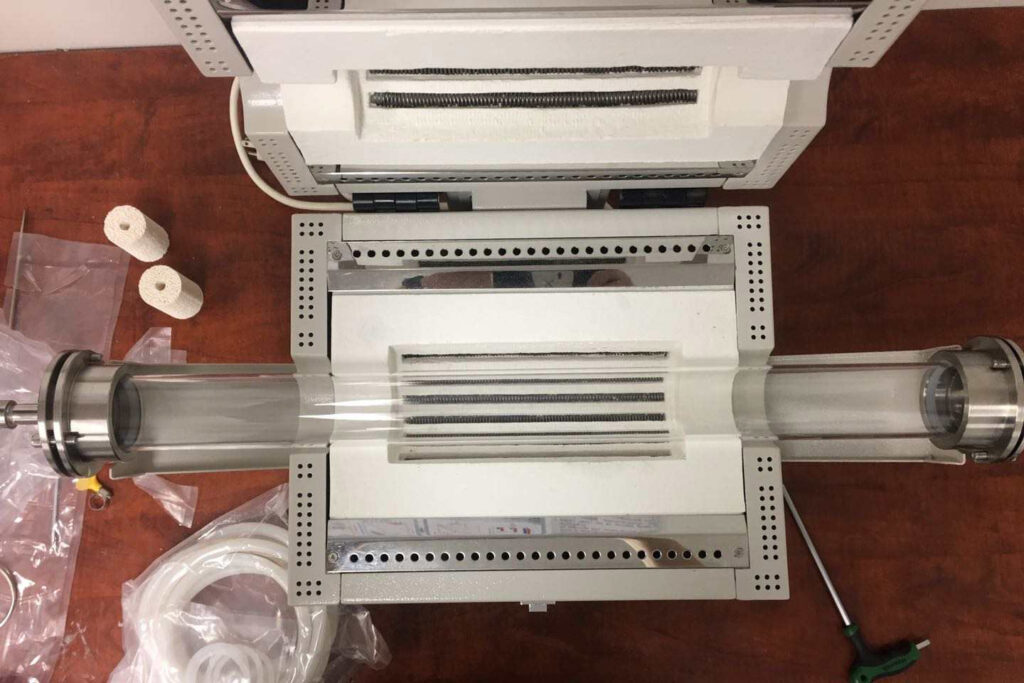

Tube furnaces are indispensable tools in both scientific research and industrial applications. Known for their precise temperature control and uniform heat distribution, these furnaces are widely used in processes such as material synthesis, sintering, annealing, and calcination.

ZYLAB is a leading scientific instrument supplier, offering furnace tubes and tube furnaces made from materials such as quartz, alumina, and stainless steel, designed for various experimental research applications.

Hydrogen plays a critical role in various processes conducted in tube furnaces, from reducing atmospheres and sintering to hydrogenation and environmental testing.

CVD reactors are widely used in fields such as semiconductors, photovoltaics, materials research, and thin-film coating. Due to their significance in high-tech applications, the price of CVD reactors is generally high. Understanding the price structure and influencing factors of CVD reactors is crucial for enterprises and research institutions.