A chamber furnace is a high-temperature heating system designed to process materials in a fully enclosed and thermally insulated box-shaped chamber. Unlike tube furnaces or open-flame systems, chamber furnaces provide a controlled environment where heating elements are embedded in the interior walls, ensuring excellent thermal uniformity.

Category Archives: Thermal Processing

Silicon carbide (SiC) heating elements are widely used in high-temperature applications such as ceramics sintering, powder metallurgy, glass processing, and laboratory heat treatment. Known for their high thermal conductivity, excellent oxidation resistance, and maximum working temperatures up to 1500°C, SiC elements are a popular choice for both industrial and research environments.

However, like all consumable components, SiC heating elements gradually degrade over time. The good news is: with proper care and operation, you can significantly extend their service life and reduce replacement costs.

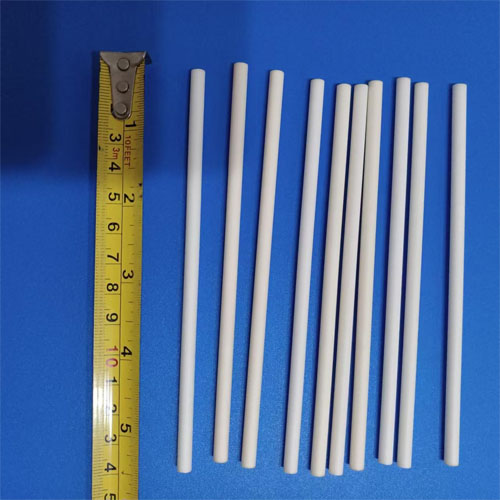

At ZYLAB, we take pride in supporting cutting-edge scientific research and advanced material development around the world. Recently, we had the opportunity to collaborate with one of Turkey’s most prominent nanotechnology innovation companies, supplying them with high-purity alumina crucibles and custom-fabricated alumina tubes for use in their precision thermal experiments.

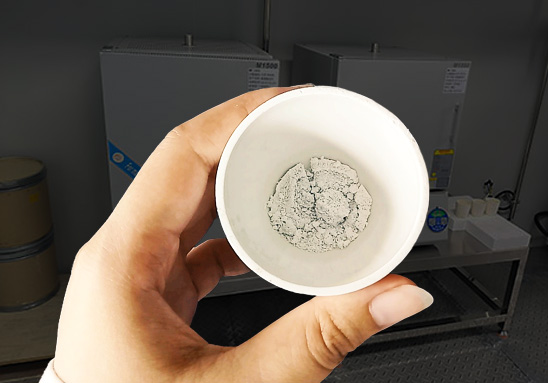

At ZYLAB, we are proud to support world-class research with high-performance ceramic materials. One of our recent collaborations involved the supply of high-purity alumina crucibles to the prestigious International Iberian Nanotechnology Laboratory (INL), located in Braga, Portugal.

At ZYLAB, we take pride in supporting advanced research institutions with precision-engineered materials and tailored thermal solutions. One of our recent collaborations involved the customization and delivery of boron nitride crucibles for the Faculty of Engineering and Applied Science at Queen’s University, Canada—a globally recognized center for cutting-edge materials and energy research.

Muffle furnaces are essential tools in modern materials research, especially for ceramic and metal sintering applications. In research and development (R&D) laboratories, where precision, repeatability, and control are paramount, muffle furnaces provide the reliable thermal environment necessary for studying advanced materials and developing new processes.

Proper installation of a muffle furnace is essential to ensure safe operation, extend the equipment’s lifespan, and maintain consistent performance. Whether you’re setting up a furnace for materials testing, ash content analysis, or other high-temperature processes, following the right procedures can make a significant difference.

In laboratory settings, the muffle furnace is an indispensable tool for precise and controlled cement calcination. This blog explores how to use a muffle furnace for cement calcination, the typical temperature ranges, best practices, common challenges, and how to improve test accuracy.

Ash content testing is a crucial process in material analysis across industries such as metallurgy, environmental science, and food safety. A muffle furnace is one of the most commonly used instruments for this task due to its ability to provide stable, high-temperature conditions for complete combustion of organic matter.

Alumina crucibles (Al₂O₃) are widely used in high-temperature applications such as ceramic sintering, metal melting, and powder heat treatment thanks to their excellent thermal stability and chemical resistance.

However, users often encounter cracking issues during use, which can lead to wasted materials, failed experiments, and production delays.