The reduction furnace is the core equipment in the hydrogen reduction process of metal oxides, providing a high-temperature environment and stable gas flow to facilitate the reduction reaction of metal oxides.

Category Archives: Thermal Processing

A hydrogen reduction furnace is a specialized high-temperature device used for reduction reactions, where hydrogen gas acts as a reducing agent to convert oxides into their corresponding metals or other reduced forms.

Whether you are involved in metal refining, powder metallurgy, or advanced ceramics, understanding the capabilities and applications of hydrogen reduction furnaces can help you optimize your processes and achieve superior results.

In the realm of modern manufacturing, Powder Metallurgy (PM) stands out as an innovative and efficient production method, gaining popularity across various industries. By utilizing metal powders or a mixture of metal and non-metal powders, this technique involves pressing and sintering to create high-precision, high-performance metal components.

When using a 1700°C high-temperature sintering furnace, it is essential to follow specific precautions to ensure safe and efficient operation.

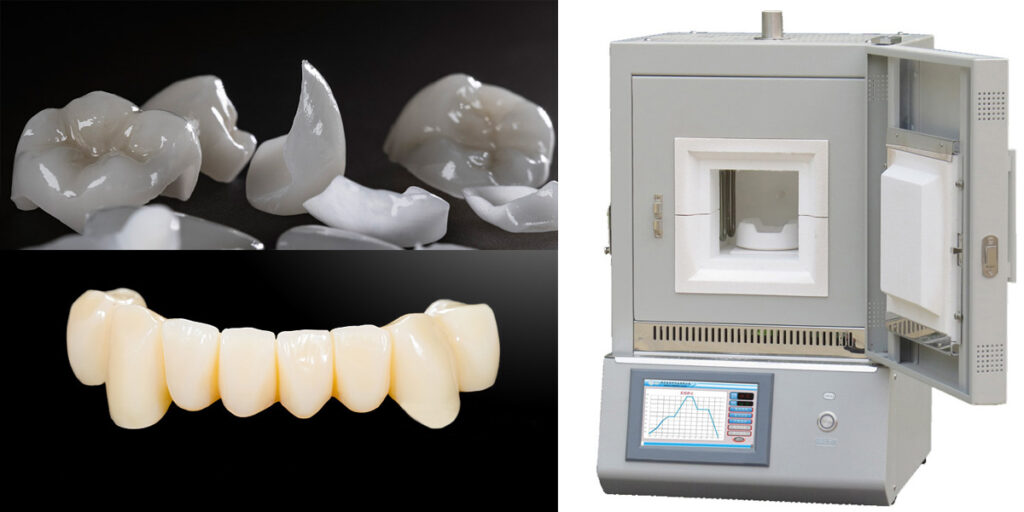

Zirconia dental prosthesis sintering involves the high-temperature sintering of zirconia ceramic materials used in dental restorations. This process densifies the zirconia particles, forming a hard, durable, and biocompatible dental prosthesis.

In the semiconductor industry, heat treatment equipment plays a crucial role in the manufacturing process, altering the physical and chemical properties of materials to meet various process requirements.

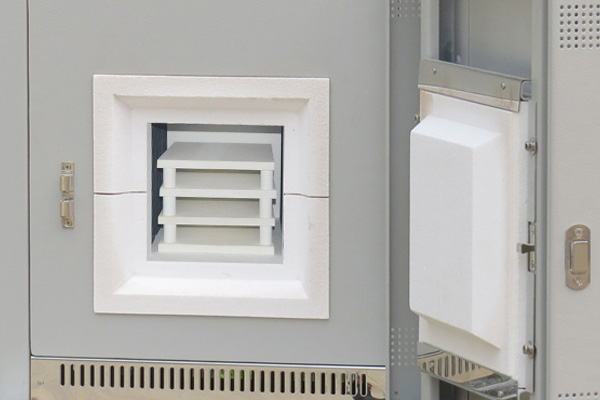

When used together in furnace furniture, alumina plates and pads create a robust solution for supporting and separating items being fired in the furnace

Laboratory furnaces serve as indispensable tools in the research and development of solid-state batteries. Their ability to provide controlled heating and cooling environments enables scientists and engineers to precisely synthesize, process, and characterize battery materials.

Furnace furniture can include crucibles, shelves, racks, supports, setters, posts, and other structures that are essential for organizing and supporting materials during heat treatment processes like firing, sintering, annealing, or heat treating.