Among various laboratory heating instruments, a 1700℃ tube furnace stands out for its high-temperature capabilities, uniform heating, and versatility in catalyst synthesis. This article explores how a 1700℃ tube furnace supports high-efficiency catalyst preparation experiments, its advantages, and practical applications.

Category Archives: Thermal Processing

This article delves into the technical role of high-temperature tube furnaces in carbon-based composite synthesis, focusing on temperature control, atmosphere management, and material uniformity—critical parameters for researchers and engineers in advanced material science.

For enterprises in the precious metals industry, the adoption of a hydrogen reduction furnace represents a leap forward in both technology and sustainability. By delivering higher efficiency, superior product purity, and reduced environmental impact, this equipment has become an indispensable tool for forward-thinking companies.

Rapid Thermal Processing (RTP) furnaces provide ultrafast heating, precise temperature control, and flexible experimental setups. They help researchers study thermal responses while preserving nanoscale structure integrity.

Clean-chamber vacuum atmosphere bottom-loading furnaces provide the precision, cleanliness, and automation needed to advance research at the interface of nanotechnology and enzyme catalysis. By enabling contamination-free processing, uniform heating, and flexible atmosphere control, these furnaces are accelerating progress in energy, medicine, catalysis, and sustainable chemistry.

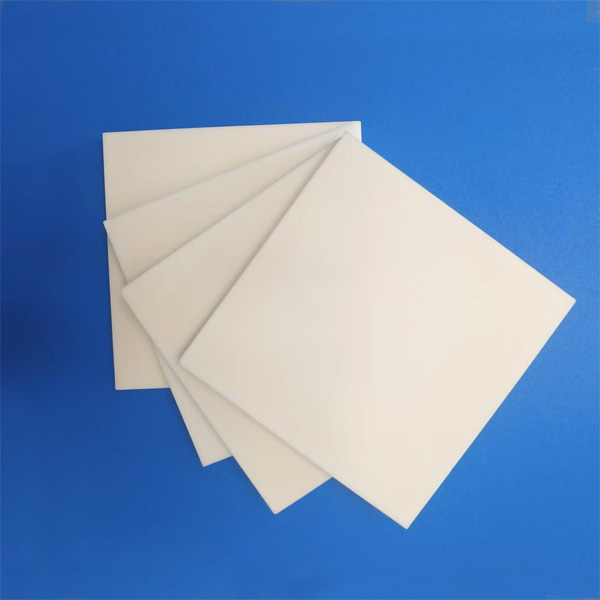

At ZYLAB, we are proud to support leading global enterprises with advanced ceramic materials. Recently, we successfully delivered a batch of high-purity alumina ceramic setter plates to TUSAŞ Engine Industries Inc. (TEI), Turkey’s leading aerospace engine manufacturer.

Tube furnaces are widely used in materials science due to their ability to deliver precise, high-temperature environments under controlled atmospheres. They play a critical role in research and development across various fields such as metallurgy, ceramics, crystal growth, and nanomaterials.

This article serves as a comprehensive guide to selecting the right furnace for ceramic sintering applications. We will explore different furnace types, key parameters such as temperature range and atmosphere control, and how to match your application needs with the right equipment.

At Zylab, we are proud to support scientific institutions across Europe with high-quality laboratory materials. One of our latest collaborations was with Linköping University in Sweden, where we supplied high-purity quartz boats for use in the ITN (Department of Science and Technology) cleanroom facility.

At ZYLAB, we take pride in supporting cutting-edge research across the globe with highly customized high-temperature solutions. Recently, we had the privilege of designing and manufacturing a lab-scale fluidized bed furnace for the Center for Heat Treating Excellence (CHTE) at Worcester Polytechnic Institute (WPI), one of the most prestigious research universities in the United States.