Table of Contents

Introduction

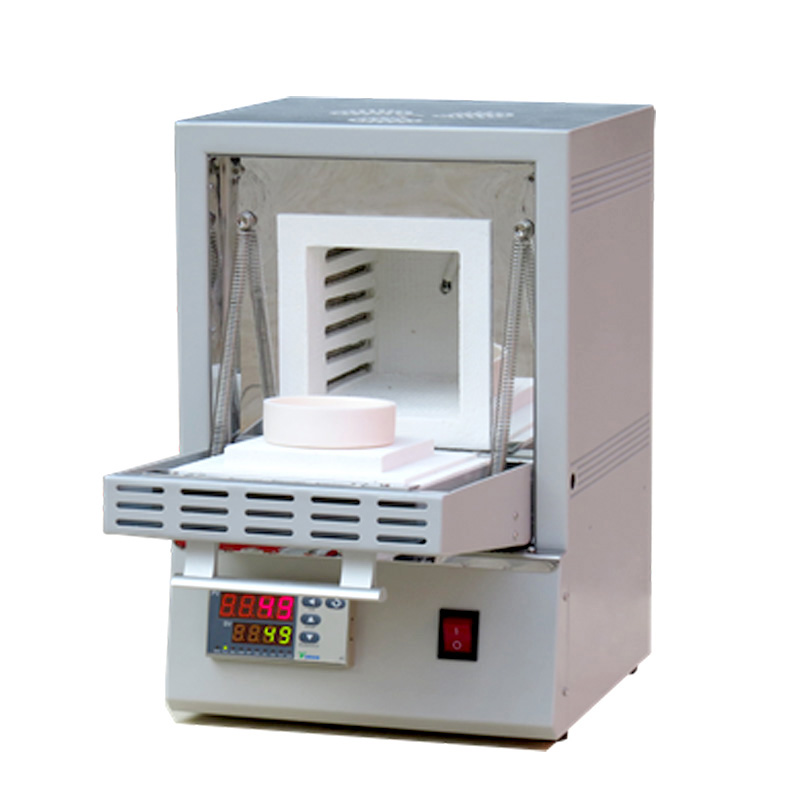

What is a Burnout furnace?

A burnout furnace, also known as a casting furnace or wax elimination furnace, is a specialized piece of equipment used in the dental and jewelry industries. It is primarily used for the process of burning out wax patterns or organic materials from investment molds before casting metal.

Here are some key points about burnout furnaces:

Purpose: The primary purpose of a burnout furnace is to eliminate wax patterns or organic materials from investment molds to create cavities or voids for casting metal. This process is essential for creating accurate and high-quality dental or jewelry castings.

Wax Elimination: Burnout furnaces are specifically designed to heat the investment molds to a high temperature, causing the wax patterns or organic materials to melt, vaporize, or burn away completely. This leaves behind a mold cavity that is ready for the casting process.

Temperature Control: Burnout furnaces provide precise temperature control to ensure that the wax elimination process is carried out effectively. They allow for ramping up the temperature gradually and holding it at specific set points to ensure complete removal of the wax or organic materials without damaging the investment mold.

Heating Elements: Burnout furnaces typically use heating elements such as resistance wire or electric coils to generate and maintain the required temperature. These elements are designed to withstand high temperatures and provide even heat distribution throughout the furnace chamber.

Ventilation System: Burnout furnaces are equipped with a ventilation system to remove any gases or fumes produced during the burnout process. Proper ventilation is crucial for maintaining a safe working environment and preventing the buildup of potentially harmful substances.

Programmable Features: Some advanced burnout furnaces offer programmable features, allowing users to pre-set specific temperature profiles and heating cycles for different casting materials or casting requirements. This automation simplifies the process and improves consistency.

Maintenance: Regular maintenance is important to ensure the proper functioning of a burnout furnace. This includes cleaning the furnace chamber, inspecting and replacing heating elements as needed, and calibrating temperature controls to maintain accuracy.

Burnout furnaces are essential tools in the dental and jewelry industries, enabling the production of high-quality castings with precise details and accurate fit. Their ability to efficiently eliminate wax patterns or organic materials from investment molds is crucial for achieving successful casting results.

Applications

What is a Burnout Furnace Used For?

Burnout furnaces have several applications in the dental and jewelry industries. Here are some common uses:

Dental Casting: Burnout furnaces are extensively used in the dental industry for casting various dental prostheses, such as crowns, bridges, inlays, and implants. The furnace is used to eliminate the wax patterns from the investment molds before casting the desired metal, such as gold, silver, or alloys, to create the final dental restorations.

Jewelry Casting: Burnout furnaces play a vital role in jewelry manufacturing. Jewelry designers and manufacturers use the furnace to burn out wax models or organic materials from investment molds to create cavities for casting precious metals, such as gold, silver, platinum, or palladium. The furnace ensures the complete elimination of the patterns, resulting in accurate and finely detailed jewelry pieces.

Sculpture Casting: Artists and sculptors use burnout furnaces for casting metal sculptures. The furnace helps remove the wax or organic materials used in the creation of the original sculpture, leaving behind a cavity that can be filled with molten metal. This allows for the replication of intricate sculptures in durable metals.

Rapid Prototyping: Burnout furnaces are utilized in rapid prototyping processes where wax models or organic materials are used to create prototypes of various products. The furnace aids in removing these materials, leaving behind a mold cavity that can be filled with the desired material for testing and evaluation before mass production.

Artistic Metalwork: Burnout furnaces find applications in artistic metalwork, such as creating intricate metal designs and ornaments. The furnace is used to eliminate wax patterns or organic materials, allowing for the casting of metal with precision and intricacy, resulting in unique and artistic metal creations.

Lost Wax Casting: Burnout furnaces are an essential component of the lost wax casting technique. This technique is widely used in the dental, jewelry, and art industries to create detailed and accurate metal castings. The furnace is used to burn out the wax or organic material from the investment molds, leaving behind a hollow cavity that is later filled with molten metal.

Burnout furnaces are versatile tools used in various industries that require the casting of metal objects. Their ability to remove wax patterns or organic materials from investment molds ensures accurate and high-quality castings for a wide range of applications.

The Application of Burnout Furnace in Dental Field

In the dental industry, a burnout furnace is commonly used for various applications in the production of dental restorations. Here are some of the key applications of a burnout furnace in the dental field:

1. Lost Wax Technique: The burnout furnace is crucial in the lost wax technique used for casting dental restorations, such as crowns, bridges, and dental implants. It is used to remove the wax pattern from the investment mold before the molten metal is poured into the mold cavity. The furnace gradually heats the mold, causing the wax to melt and burn out, leaving behind a cavity that is ready for casting with the chosen dental alloy.

2. Ceramic Restorations: In dental laboratories, a burnout furnace is also used for the production of ceramic restorations, such as porcelain-fused-to-metal (PFM) crowns or all-ceramic crowns. The furnace is utilized to remove the organic binders or additives from the ceramic material before it is fired at high temperatures. This process ensures proper bonding and aesthetic properties of the final dental restoration.

3. Removable Partial Dentures: Burnout furnaces are utilized in the fabrication of removable partial dentures that involve metal frameworks. The furnace is used to eliminate the wax patterns and any residual organic materials before investing the metal framework for casting. This step ensures precise fitting and proper integration of the metal framework with the denture base material.

4. Dental Implant Manufacturing: Burnout furnaces play a role in the production of dental implant components. They are used to remove the wax patterns or resin materials from the investment molds before casting the implant components with biocompatible materials, such as titanium or zirconia.

Overall, a burnout furnace is an essential tool in the dental industry for various applications related to casting, ceramics, and removable dental prostheses. It enables the removal of organic materials, allowing for the production of accurate and high-quality dental restorations.

Benefit

The use of burnout furnaces in dental and jewelry applications offers several benefits:

Wax Elimination: Burnout furnaces are specifically designed to effectively and completely eliminate wax patterns or organic materials from investment molds. This ensures that the final castings are free from any residue, resulting in clean and accurate cavities ready for casting metal.

Accurate Castings: By removing the wax patterns or organic materials with precision, burnout furnaces help ensure the accuracy and fidelity of the final castings. This is particularly important in dental and jewelry applications, where intricate details and precise fits are crucial for the functionality and aesthetics of the end products.

Improved Casting Quality: The use of burnout furnaces helps minimize the risk of defects and imperfections in castings. By removing the wax or organic materials completely, the furnace eliminates potential sources of porosity, air pockets, or other casting irregularities, resulting in higher-quality final products.

Versatility: Burnout furnaces are versatile tools that can accommodate a wide range of casting materials, including various metals and alloys used in dental and jewelry applications. This flexibility allows for the production of diverse and customized products to meet specific requirements and design preferences.

Time Efficiency: Burnout furnaces contribute to time efficiency in the casting process. They are designed to heat the investment molds to the necessary temperature for wax elimination quickly and efficiently, reducing the overall production time. This is particularly advantageous in industries where fast turnaround times are required.

Consistency and Reproducibility: Burnout furnaces offer precise temperature control and programmable features, ensuring consistent and reproducible results in casting. By following predetermined temperature profiles and heating cycles, the furnace helps achieve consistent outcomes, reducing variability between castings and enhancing production efficiency.

Safety and Environmental Considerations: Burnout furnaces are designed with safety features, such as ventilation systems, to remove gases and fumes generated during the burnout process. This ensures a safe working environment for operators. Additionally, the elimination of wax patterns or organic materials in a controlled and efficient manner reduces the environmental impact associated with these materials.

Overall, the use of burnout furnaces provides numerous benefits, including improved casting quality, accuracy, versatility, time efficiency, and safety. These benefits contribute to the production of high-quality dental restorations, jewelry pieces, and other metal castings in various industries.

Burnout Furnace Price

The price of a burnout furnace can vary depending on several factors such as the brand, model, features, and additional accessories included.

Generally, burnout furnaces can range in price from a few hundred dollars to a few thousand dollars. Entry-level or basic models may be available at a lower price range, while more advanced models with additional features and higher capacity can be more expensive.

It’s important to note that the price can also be influenced by the specific technology used in the furnace, such as muffle or induction heating.

To get the most accurate and up-to-date pricing information, recommend contacting us directly. We can provide you with detailed information on pricing and any available options or packages that suit your requirements.

Temperature and Heating Capacity: Consider the maximum temperature the furnace can reach and whether it meets the requirements for the materials and processes you work with. Additionally, check the heating capacity and the size/volume of the furnace chamber to ensure it can accommodate your workload.

Heating Technology: Burnout furnaces typically use either muffle heating or induction heating technology. Each technology has its advantages and considerations. Muffle furnaces are more commonly used and are generally more affordable, while induction furnaces provide faster heating and more precise temperature control.

Programmability and Controls: Look for a furnace that offers programmable settings and precise controls. The ability to set and control temperature profiles, ramp-up rates, and hold times is crucial for achieving optimal results. User-friendly interfaces and intuitive controls can make operation easier.

Safety Features: Consider the safety features provided by the furnace, such as over-temperature protection, ventilation systems, and automatic shut-off. Safety should be a priority to protect both the operator and the equipment.

Chamber Design and Construction: Evaluate the design and construction of the furnace chamber. Look for features such as good insulation, even heat distribution, and easy cleaning. A well-designed chamber can contribute to consistent and reliable burnout results.

Maintenance and Support: Check the maintenance requirements of the furnace and inquire about the availability of technical support, warranty, and after-sales service. Having access to reliable support can be crucial in case of any issues or questions that may arise during the furnace’s lifespan.

Price and Budget: Determine your budget and consider the value for money offered by different furnace models.

User Reviews and Recommendations: Read reviews and seek recommendations from other dental professionals or colleagues who have experience with the specific furnace models you are considering. Their insights can provide valuable information about the performance, reliability, and user experience.

By carefully considering these factors, you can make an informed decision and choose a burnout furnace that meets your specific requirements and offers the best value for your investment.

FAQ

Q: How does a burnout furnace work?

A: A burnout furnace works by heating investment molds containing wax patterns or organic materials to a high temperature. The furnace gradually increases the temperature to melt, vaporize, or burn away the wax or organic materials, leaving behind a cavity in the investment mold. This cavity is then ready for the casting of molten metal.

Q: What types of materials can be eliminated in a burnout furnace?

A: Burnout furnaces are primarily used to eliminate wax patterns in dental and jewelry applications. However, they can also remove other organic materials used for rapid prototyping or artistic metalwork. It is important to follow the manufacturer’s guidelines and ensure that the materials used are suitable for burnout.

Q: Can a burnout furnace handle different casting materials?

A: Yes, burnout furnaces can handle various casting materials such as gold, silver, platinum, palladium, and their alloys. The furnace’s temperature control and programmable features allow for customization based on the specific melting points and casting requirements of different materials.

Q: How long does a typical burnout process take?

A: The duration of a burnout process can vary depending on factors such as the size and complexity of the wax patterns or organic materials, the type of casting material, and the specific requirements of the casting process. Generally, a burnout process can take several hours, including both the heating and cooling phases.

Q: How often should a burnout furnace be maintained?

A: Regular maintenance is important to ensure the proper functioning of a burnout furnace. This includes cleaning the furnace chamber, inspecting and replacing heating elements as needed, calibrating temperature controls, and following the manufacturer’s recommendations for maintenance intervals. It is important to consult the manufacturer’s guidelines for specific maintenance requirements.

Q: Can a burnout furnace be used in both dental and jewelry applications?

A: Yes, burnout furnaces are commonly used in both dental and jewelry applications. They are versatile tools suitable for eliminating wax patterns and organic materials from investment molds in various casting processes, including those specific to dental prosthetics and jewelry manufacturing.

Q: Are there any safety considerations when using a burnout furnace?

A: Yes, safety considerations should be followed when using a burnout furnace. This includes ensuring proper ventilation to remove gases and fumes, using appropriate personal protective equipment, and following the manufacturer’s instructions for safe operation. It is essential to provide a safe working environment for operators and comply with all safety regulations.

Q: What is the temperature of burnout furnace?

A: The temperature of a burnout furnace used in dental applications typically ranges from approximately 800°C (1472°F) to 1200°C (2192°F). The specific temperature required for a burnout process depends on various factors, including the type of investment material used, the specific dental procedure and etc.

During the burnout process, the furnace gradually raises the temperature to eliminate any residual wax or organic materials from the investment mold before casting.