Table of Contents

Bridgman furnaces are essential tools in the field of crystal growth, particularly for producing high-quality single crystals used in semiconductors, thermoelectric materials, and optical applications. For those exploring this technology, understanding the price and value of a Bridgman furnace is crucial.

In this article, we’ll explore the factors influencing the cost of a Bridgman furnace, the benefits it offers, and how ZYLAB’s Bridgman furnaces stand out in terms of performance and affordability.

What Is a Bridgman Furnace?

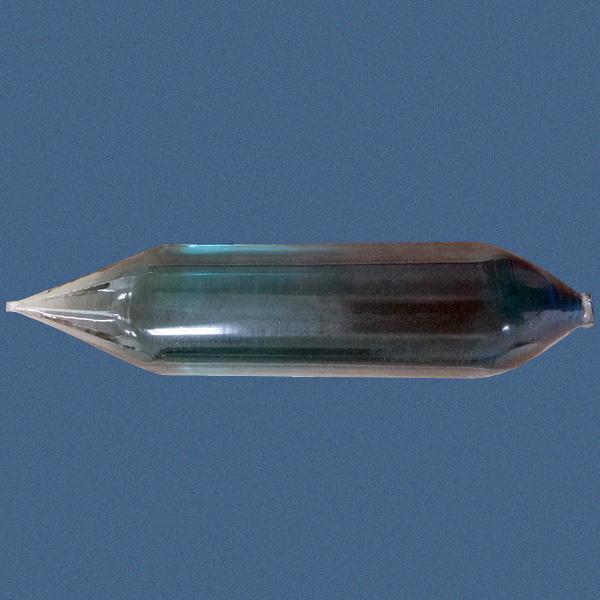

A Bridgman furnace is designed to facilitate the controlled growth of single crystals through the Bridgman-Stockbarger method. This method involves slowly cooling a molten material while maintaining a controlled temperature gradient, ensuring the gradual solidification of the crystal.

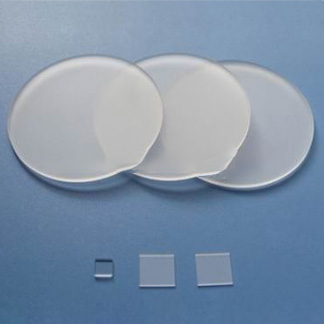

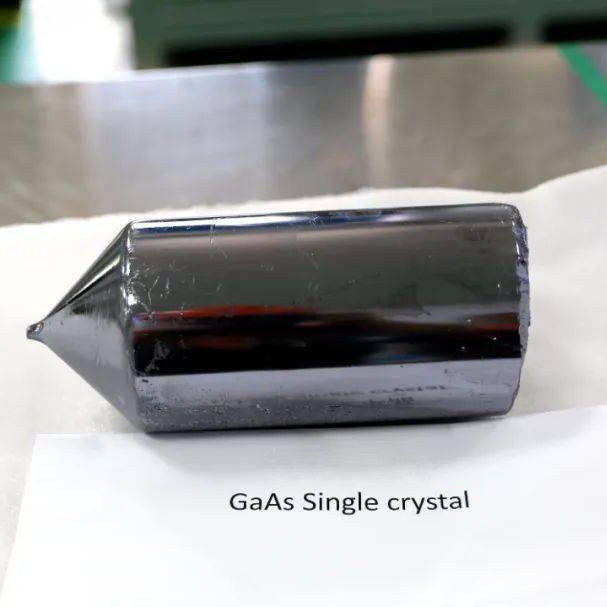

Materials such as BiTe (bismuth telluride), GaAs (gallium arsenide), and sapphire are commonly grown using this technique.

We offer a variety of crystal materials and substrates. For detailed information and pricing, please contact us now.

Key Factors Affecting Bridgman Furnace Price

The price of a Bridgman furnace varies widely depending on several factors:

Maximum Operating Temperature:

Furnaces capable of reaching higher temperatures (e.g., above 1600°C) typically cost more due to the need for advanced heating elements and insulation materials.

Temperature Gradient Control:

Precision in temperature gradient is critical for high-quality crystal growth. Furnaces with advanced control systems, such as PID controllers or multi-zone heating, are generally more expensive.

Furnace Size and Capacity:

Larger furnaces designed for industrial-scale applications cost significantly more than smaller, laboratory-sized units.

Customization Options:

Features like atmosphere control (vacuum or inert gas), rotational mechanisms, and additional cooling systems contribute to the overall price.

Brand and Build Quality:

Trusted manufacturers like ZYLAB offer reliable equipment backed by robust customer support, which may slightly increase the upfront cost but ensures long-term value.

Average Price Range

Entry-Level Models: Smaller laboratory Bridgman furnaces with basic features typically range from $5,000 to $15,000.

Mid-Range Models: Furnaces with advanced temperature control and larger capacities cost between $15,000 and $50,000.

High-End Models: Industrial Bridgman furnaces designed for large-scale production or high-temperature applications can exceed $100,000.

Why Choose ZYLAB’s Bridgman Furnace?

ZYLAB specializes in designing and manufacturing Bridgman furnaces tailored to meet diverse application requirements. Here are some key features of ZYLAB’s Bridgman furnaces:

Precise Temperature Control:

Multi-zone heating elements ensure a stable and adjustable temperature gradient, ideal for producing defect-free crystals.

Customizable Design:

ZYLAB offers customization options such as rotational mechanisms, vacuum integration, and gas flow control to optimize crystal growth for specific materials like BiTe or GaAs.

Energy Efficiency:

Advanced insulation and energy-saving technologies reduce operational costs over time.

Competitive Pricing:

While maintaining high quality, ZYLAB ensures its products remain competitively priced, making advanced crystal growth technology accessible to a broader audience.

Comprehensive Support:

From initial consultation to after-sales service, ZYLAB provides end-to-end support, ensuring optimal performance and longevity of the furnace.

Conclusion

Investing in a Bridgman furnace requires a thorough understanding of its features and pricing. While the initial cost may vary based on specifications and brand, the long-term benefits of precision, efficiency, and reliability make it a valuable asset for researchers and manufacturers.

For those seeking high-quality and cost-effective solutions, ZYLAB’s Bridgman furnaces offer a perfect balance of performance and affordability.

Whether you’re exploring crystal growth for thermoelectric materials like BiTe or optical crystals like sapphire,ZYLAB is ready to meet your needs.

Contact us today to learn more about our Bridgman furnace options and receive a personalized quote tailored to your requirements.

Share this entry

You might also like