Introduction

Conductive silver paste is a crucial material in advanced electronics, photovoltaics, and printed circuit boards. With the growing demand for high-performance conductive materials, researchers are continuously developing new formulations to enhance conductivity, adhesion, and durability.

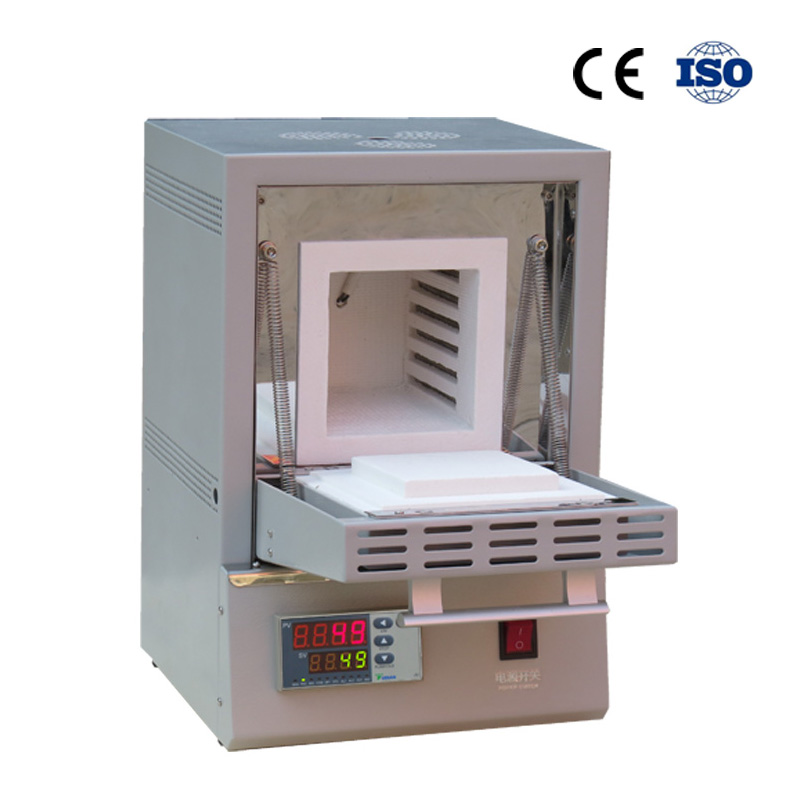

Box furnaces play a vital role in this research, providing precise thermal processing conditions necessary for sintering and curing silver pastes.

Importance of Thermal Treatment in Conductive Silver Paste Research

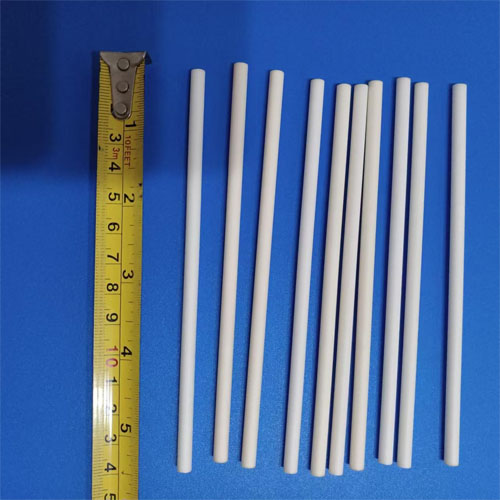

The performance of conductive silver paste depends on several factors, including particle size, binder composition, and sintering temperature. Thermal treatment is a critical step in optimizing these properties, as it influences the formation of conductive pathways and the overall material stability.

Box furnaces offer a controlled environment where temperature, heating rate, and dwell time can be precisely adjusted to achieve desired material characteristics.

How Box Furnaces Enhance Silver Paste Development

- Precise Temperature ControlZYLAB box furnaces provide uniform heating with advanced temperature controllers, essential for sintering silver particles and achieving optimal electrical conductivity. Controlled heating profiles prevent defects such as cracking or incomplete sintering.

- Atmosphere ControlSome silver pastes require specific atmospheres (e.g., nitrogen or forming gas) to prevent oxidation and enhance conductivity. ZYLAB box furnaces support atmosphere customization, ensuring optimal sintering conditions.

- Batch Processing for ConsistencyCompared to other thermal processing methods, box furnaces allow batch processing of multiple samples under identical conditions, ensuring consistency and reproducibility in material development. ZYLAB furnaces are designed for stable operation and high repeatability.

- Customizable Heating ProfilesDifferent silver pastes require specific heating rates and cooling curves. ZYLAB box furnaces enable researchers to fine-tune these parameters to enhance adhesion, reduce porosity, and improve conductivity, thanks to their programmable PID temperature control.

- Versatility for Multi-Material ResearchIn addition to silver paste, ZYLAB box furnaces can be used for various conductive materials, making them ideal for comparative studies and multi-material research.

Applications of Conductive Silver Paste Developed with Box Furnaces

The advanced conductive silver pastes developed using ZYLAB box furnaces are widely used in:

- Photovoltaic Cells: Improving the efficiency of solar panels.

- Flexible Electronics: Enabling conductive pathways in wearable technology.

- Printed Circuit Boards (PCBs): Enhancing signal transmission and durability.

- RFID and Antenna Applications: Supporting the development of high-frequency communication devices.

Conclusion

Box furnaces are indispensable tools in the research and development of new conductive silver paste materials. Their precise temperature control, customizable atmospheres, and consistent batch processing capabilities enable researchers to optimize material properties for various high-tech applications.

With their reliable performance and user-friendly features, ZYLAB box furnaces accelerate advancements in conductive materials, making them essential equipment for laboratories and research institutions.

For more details on how ZYLAB furnaces can support your research, contact us today!