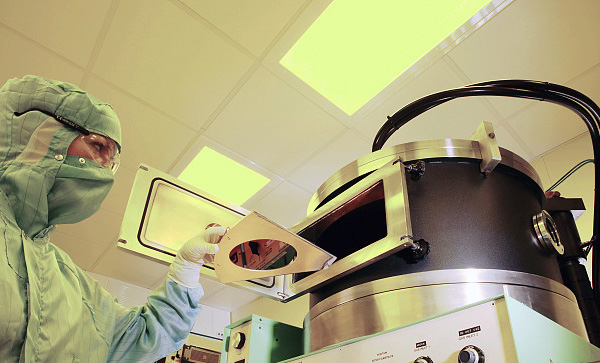

How to Choose the Right PECVD Furnace?

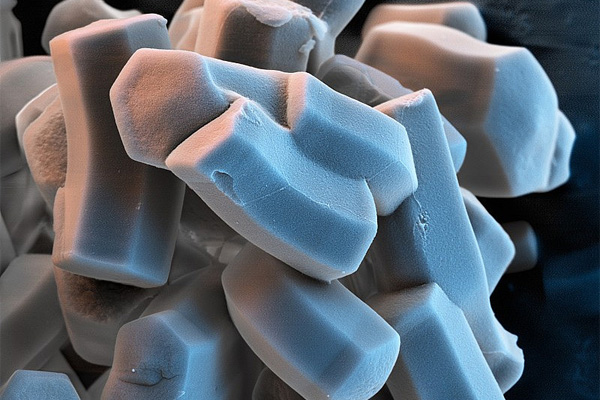

Plasma-Enhanced Chemical Vapor Deposition (PECVD) furnaces are essential for thin-film deposition in industries such as semiconductors, optics, photovoltaics, and MEMS. Choosing the right PECVD furnace is crucial to achieving high-quality film coatings with precise control over deposition parameters.