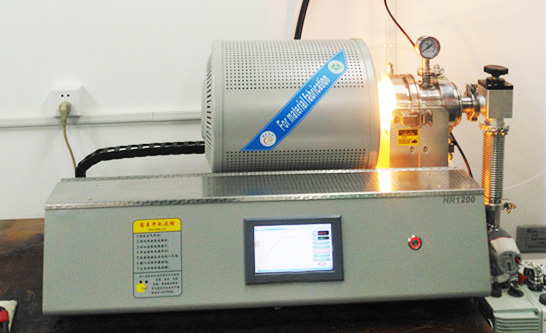

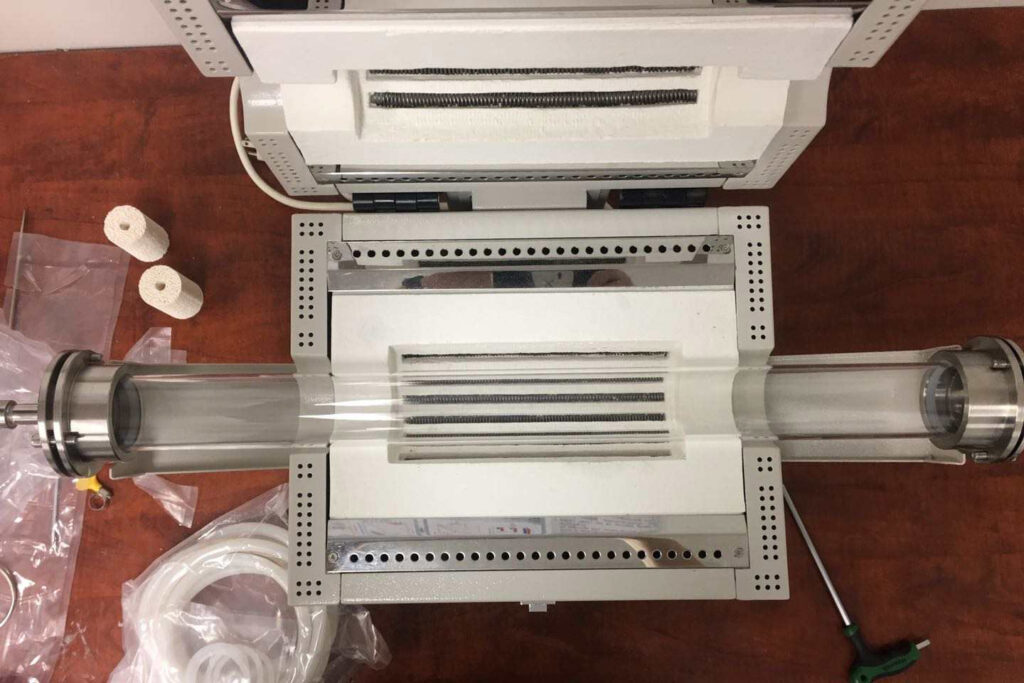

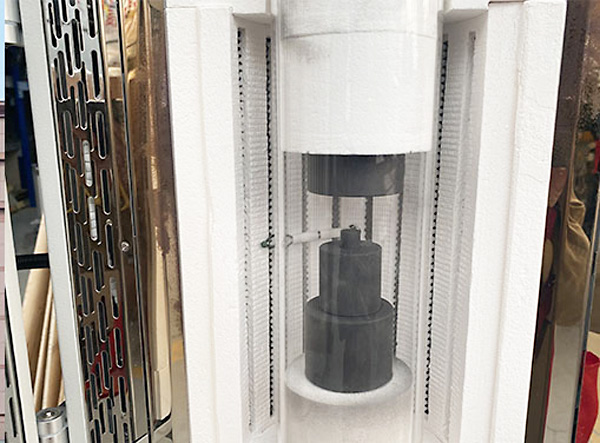

The Role of a 1200°C Vacuum Hot Press Furnace in Metal Powder Densification and Ceramic Material Sintering

The 1200°C Vacuum Hot Press Furnace is a powerful tool for both metal powder densification and ceramic material sintering. Its ability to operate under high pressure and in a controlled vacuum environment allows for precise material treatment, leading to enhanced material properties and reduced defects.