What Is a Vacuum Tube Furnace?

Vacuum tube furnaces are versatile tools for materials processing, heat treatment, and various research applications.

Vacuum tube furnaces are versatile tools for materials processing, heat treatment, and various research applications.

Two zone tube furnace used in various industrial, research, and laboratory settings for processes like material synthesis, heat treatment, and more.

Tubular furnaces are versatile tools for high-temperature applications, materials processing, and various research processes.

It features three independently controlled heating zones within a single tube, making it suitable for applications that require specific thermal profiles or temperature gradients. These furnaces are widely used in materials processing, research, and industrial applications.

Split tube furnaces are versatile tools for materials processing, heat treatment, and various high-temperature processes.

A quartz tube furnace is a specialized high-temperature heating device used for materials processing, chemical reactions, and heat treatment. These furnaces are versatile and find applications in various industries and scientific research.

Applications:

Solvent Removal

Purification

Extraction

Sample Preparation

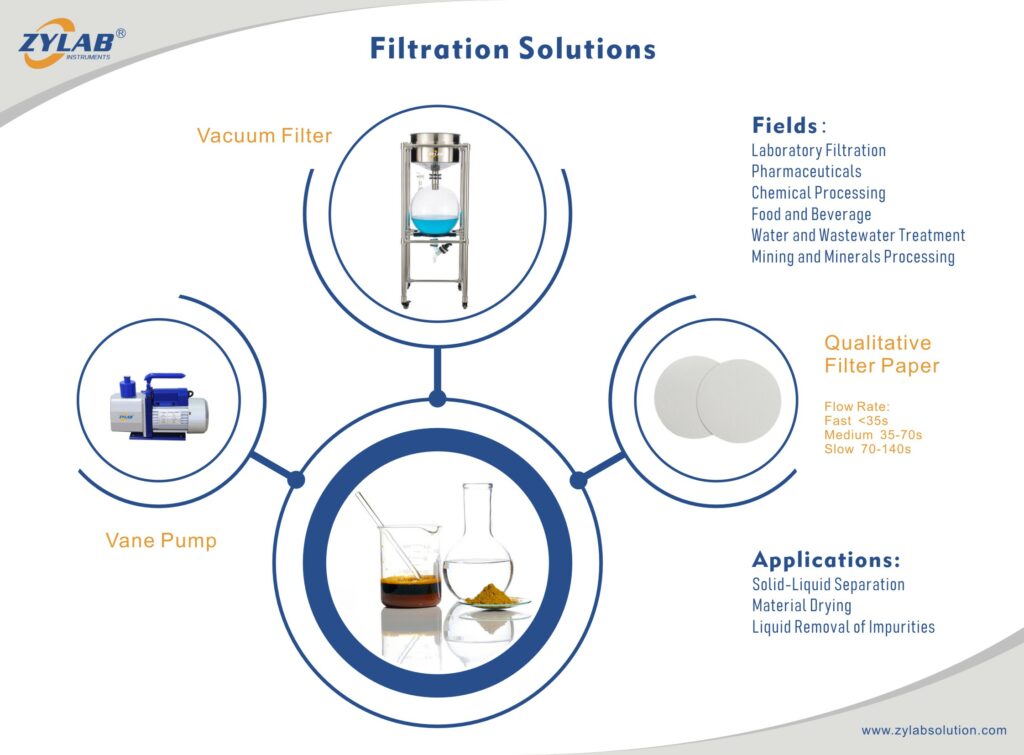

Applications:

Solid-liquid Separation

Material Drying

Liquid Removal of Impurities

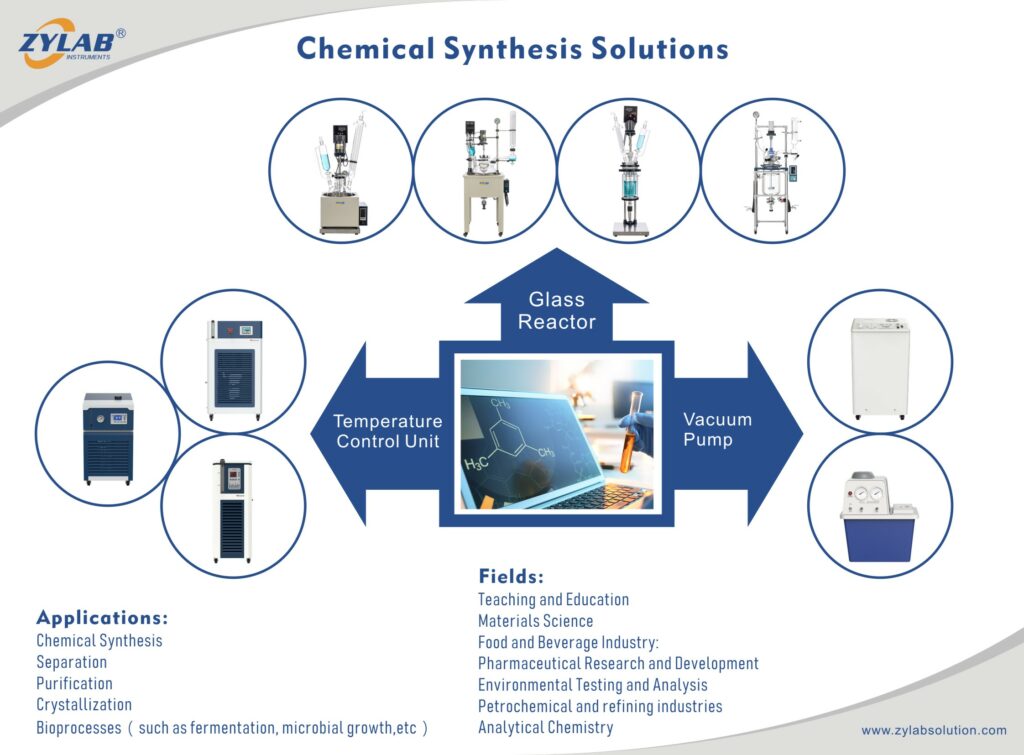

Applications:

Chemical Synthesis

Separation

Purification

Crystallization

Bioprocesses: such as fermentation, microbial growth,etc

Notifications

Welcome to ZYLAB.

Ask us anyting :)