Table of Contents

Introduction

What is biochar?

Biochar is a solid carbonaceous material obtained from the thermochemical treatment of biomass under anaerobic or oxygen-limited conditions.

It has been widely applied in various fields including soil improvement, soil remediation, water pollution treatment, crop yield enhancement, and carbon sequestration.

Biochar formed by the pyrolysis and carbonization of biomass possesses a high and stable carbon content, which can reduce carbon emissions generated by biomass combustion and natural degradation (carbon negativity).

When applied to soil, biochar can sequester carbon in the soil while simultaneously improving and/or remediating soil conditions.

Additionally, the bio-oil and syngas produced during biomass pyrolysis can serve as alternative energy sources to fossil fuels (carbon neutrality).

Raw Materials

The raw materials for biochar production are abundant and low-cost, mainly including agricultural waste (straw, fruit shells, manure, etc.), forestry waste (branches, sawdust, bark, etc.), and municipal waste (household garbage, sludge, etc.). Transforming these solid wastes into biochar effectively achieves resource utilization of solid waste.

Furthermore, using invasive plants (such as water hyacinth, water lettuce) and nutrient-rich algae (diatoms, green algae, blue-green algae, dinoflagellates, etc.) as feedstocks for biochar production can simultaneously achieve the goals of invasive species control and resource utilization.

Preparation Methods

The preparation methods of biochar are simple, typically involving thermochemical treatment at moderate temperatures (300~800°C). Common thermochemical methods include slow pyrolysis, fast pyrolysis, hydrothermal carbonization, flash carbonization, gasification, etc.

Biochar, as an effective medium, can generate comprehensive benefits in environmental, climatic, energy, agricultural, and economic aspects, attracting widespread attention from scientists, policymakers, and companies worldwide, and has long been a research hotspot in relevant fields both domestically and internationally.

Biochar Properties

Physical Properties

Porosity: Biochar typically possesses abundant porosity, including micropores, mesopores, and macropores, which contribute to its adsorption capacity and surface activity.

Specific Surface Area: The specific surface area of it is relatively high, typically ranging from 100 to 1000 square meters per gram, depending on the raw materials and preparation conditions. A higher specific surface area helps enhance its adsorption capacity.

Pore Distribution: The pore distribution of it’s significantly influences its adsorption and permeation properties, usually including micropores, mesopores, and macropores.

Chemical Properties

Carbon Content: Biochar is mainly composed of carbon, with carbon content typically ranging from 50% to 95%, depending on the raw materials and preparation conditions.

Ash Content: The ash content in it’s relatively low, usually ranging from 1% to 10%, depending on the purity of the raw materials and the processing during carbonization.

Functional Groups: Various functional groups may exist on the surface, such as hydroxyl groups, carboxyl groups, ketone groups, etc., which influence its adsorption and catalytic properties.

pH Value: The pH value of it’s typically ranges from 7 to 10, which can affect its effectiveness in applications such as soil improvement and wastewater treatment.

Application Properties

Adsorption Performance: Biochar exhibits excellent adsorption performance and can adsorb pollutants such as organic substances and heavy metals in water, making it suitable for applications in wastewater treatment and water purification.

Soil Improvement Performance: It’s can improve soil structure, increase soil aeration, water retention capacity, and enhance soil fertility, promoting plant growth.

Carbon Sequestration Performance: It’s can stably sequester carbon, helping mitigate the increase of atmospheric carbon dioxide and providing a certain degree of relief for climate change.

Key Areas of Biochar R&D

Research and development (R&D) in the field of biochar involves exploring various aspects of this carbon-rich material derived from biomass pyrolysis. Here are some key areas of biochar R&D:

Production Methods: Researchers are constantly refining and developing methods for producing biochar from different biomass feedstocks. This includes optimizing pyrolysis processes for efficiency, yield, and quality of biochar produced.

Characterization: Understanding the physical, chemical, and structural properties of it is crucial for its application in different fields. R&D efforts focus on characterizing biochar to determine its suitability for various applications such as soil amendment, carbon sequestration, water filtration, and more.

Soil Amendment: It is widely studied for its potential as a soil amendment to improve soil fertility, structure, and water retention. Research in this area includes investigating the effects of biochar on soil microbial activity, nutrient availability, and overall soil health.

Carbon Sequestration: Biochar has the potential to sequester carbon in soils for long periods, mitigating greenhouse gas emissions and combating climate change. R&D efforts focus on quantifying the carbon sequestration potential of biochar and understanding the factors that influence its stability in soil.

Waste Valorization: Biochar production offers a way to valorize biomass waste streams, including agricultural residues, forestry residues, and organic waste. R&D in this area aims to identify suitable feedstocks and develop efficient processes for converting waste biomass into biochar.

Water Treatment: Biochar can be used as a filter media for water treatment, removing contaminants such as heavy metals, organic pollutants, and nutrients from wastewater and stormwater.

Research focuses on optimizing biochar properties and deployment methods for effective water treatment applications.

Biological Applications: Biochar shows potential in various biological applications, including livestock farming, aquaculture, and bioremediation. R&D efforts explore the use of biochar as a feed additive, substrate for microbial growth, and remediation agent for contaminated soils and water bodies.

Economic Viability and Scale-up: Research aims to assess the economic feasibility of biochar production and utilization at different scales. This includes evaluating the costs associated with biochar production, application, and potential revenue streams from its various uses.

Overall, biochar R&D is multidisciplinary, involving expertise from fields such as chemistry, agronomy, environmental science, and engineering, with the ultimate goal of harnessing the potential of it for sustainable agriculture, environmental remediation, and climate change mitigation.

Economic Viability of Biochar Production

Biochar production may be economically viable under certain circumstances, depending on various factors such as raw material costs, production processes, market demand, etc. The following are some key factors influencing the economic viability of biochar production:

Raw Material Costs: Biochar raw materials typically include biomass such as wood, straw, crop residues, etc. The cost of raw materials directly affects it’s production cost. Fluctuations in raw material prices may also affect production costs and profit margins.

Production Processes: Different biochar production processes may have different costs and efficiencies. Optimized production processes can reduce energy consumption, improve production efficiency, and ultimately lower production costs.

Market Demand: Market demand for it is a crucial factor affecting its economic viability. If there is high demand and a stable market, biochar production may have higher economic benefits.

Value-added Products: Biochar production may generate by-products such as bio-oil, thermal energy, etc. These value-added products can increase revenue and improve economic benefits.

Policy Support: Government policies, subsidies, and incentive measures may also affect the economic viability of biochar production.

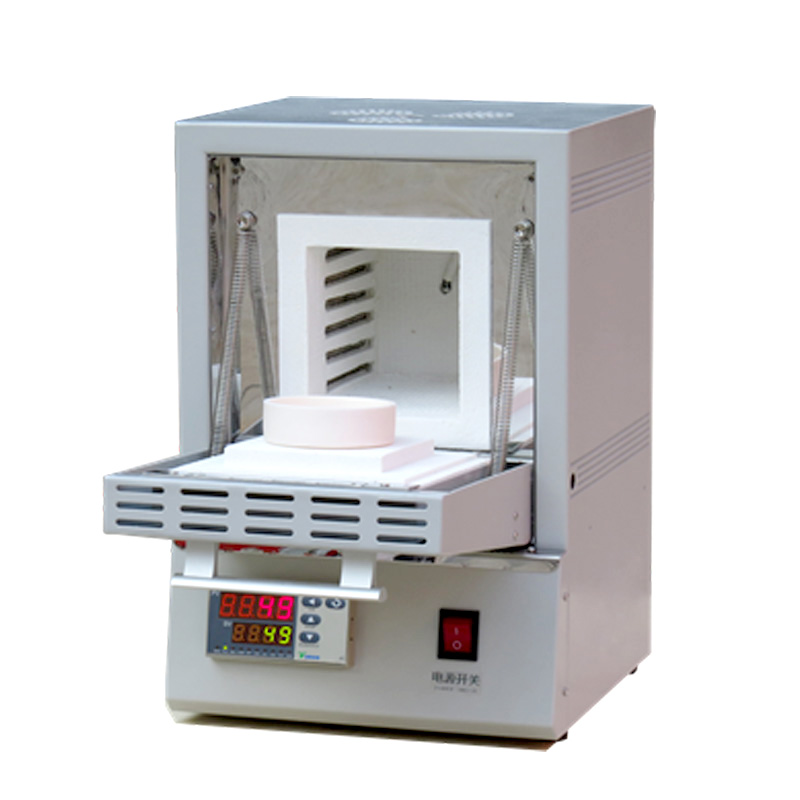

Related Laboratory Furnaces for Biochar R&D

How to choose a electric furnace suitable?

When selecting an electric furnace suitable for biochar research and development (R&D), consider the following factors:

Temperature Range: Choose an electric furnace with a temperature range that covers the required carbonization temperatures, usually between 300°C to 800°C.

Temperature Control: Ensure the electric furnace has a precise temperature control system to achieve accurate and stable temperature control.

Heating Elements: Select an electric furnace with high-quality heating elements that can withstand prolonged exposure to high temperatures without degradation.

Chamber Size: Consider the size of the reaction chamber in the electric furnace to accommodate the size and quantity of biochar samples needed for R&D experiments.

Safety Features: Choose an electric furnace with built-in safety features such as overtemperature protection, short circuit protection, and emergency shut-off mechanisms to ensure operator safety and prevent equipment damage.

Ease of Maintenance: Select an electric furnace that is easy to maintain and clean.

Budget Considerations: Determine your budget constraints and evaluate electric furnaces within your price range.

FAQ

1. Can muffle furnace be used for pyrolysis?

In some research work, such as: a biochar was obtained through a slow pyrolysis process of maize cob waste. This experiment was carried out using a small-scale muffle furnace and subjecting the feedstock to heating at different temperatures (300, 400, 500 °C).

2. What to do if incomplete pyrolysis occurs during high-temperature processing?

Incomplete pyrolysis can be addressed by increasing the carbonization temperature, extending the carbonization time, optimizing carbonization process parameters, and selecting appropriate biomass feedstock. Additionally, controlling the heating rate is crucial in resolving this issue.

3. How to ensure the stability of the quality and performance of biochar?

Ensure the stability of biochar quality and performance by equipping precision temperature control equipment and rigorously monitoring and adjusting the temperature during the carbonization process to ensure it remains within the appropriate range.