Choosing the right crucible can directly affect the outcome of your experiment, influencing material purity, structural integrity, and overall efficiency. This article compares five commonly used laboratory crucibles—Alumina, Quartz, Magnesia, Boron Nitride, and Graphite—helping you make an informed decision based on your specific application needs.

Author Archives: ZYLAB Solution

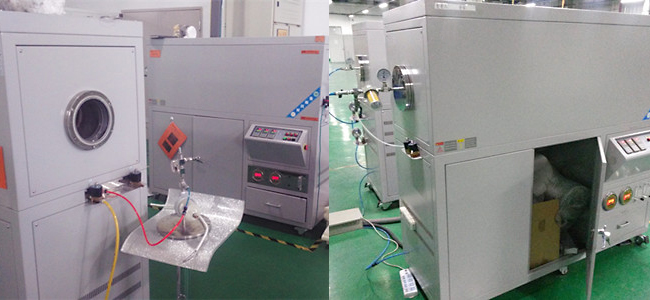

Vacuum furnaces have become indispensable tools in modern material preparation, offering high-purity environments and accurate temperature control. From advanced ceramics to semiconductor wafers, vacuum furnaces play a vital role in producing high-quality materials that meet the demanding standards of today’s industries.

Large-diameter tube furnaces play a vital role in scaling up battery material production while ensuring uniform heating, high-purity processing, and energy efficiency. In this article, we explore how large-diameter tube furnaces are revolutionizing the production process of battery materials.

Laboratory molten salt electric heating furnaces are reshaping aluminum electrolysis research and development, offering energy efficiency, precise control, and environmental benefits. As the aluminum industry transitions toward green and sustainable manufacturing, these furnaces will play an increasingly important role in achieving carbon neutrality goals.

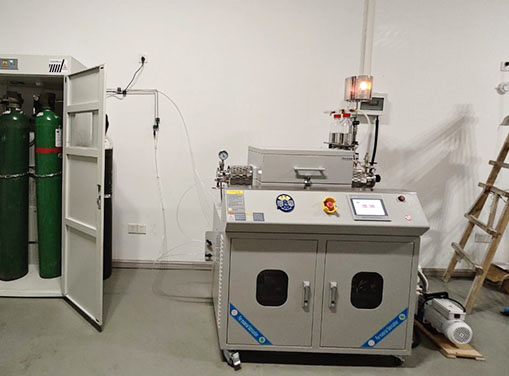

One of the most effective methods for achieving high-purity semiconductor materials is hydrogen purge reduction in a controlled furnace environment. Hydrogen purge reduction furnaces provide an optimal atmosphere to remove oxides and impurities from semiconductor materials, thereby enhancing electrical properties and improving overall device efficiency.

A large-diameter tube furnace offers a controlled environment for high-temperature processing, enabling uniform heating, scalable production, and atmosphere control. This article explores how a large-diameter tube furnace optimizes LED phosphor production and its advantages over conventional methods.

Achieving precise temperature control, uniform heating, and a clean atmosphere is essential for the success of wafer annealing. This is where large-diameter tube furnaces play a vital role.

In this blog, we will discuss the role of large-diameter tube furnaces in wafer annealing, their key features, technical specifications, and the benefits they offer to the semiconductor industry.

While traditional synthesis methods such as solvothermal and hydrothermal techniques dominate MOF fabrication, Chemical Vapor Deposition (CVD) has emerged as an innovative alternative. CVD enables precise control over MOF structure and composition, enhancing scalability and functional properties.

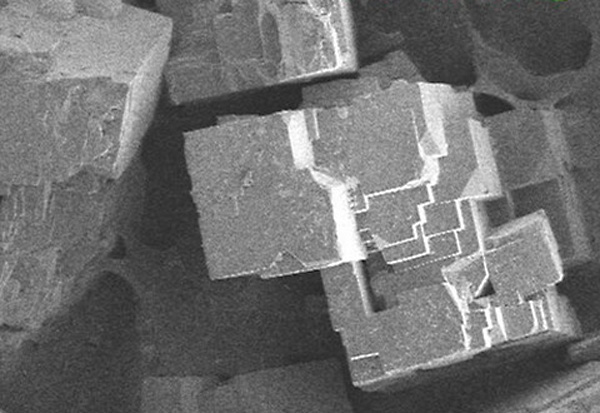

Among the various synthesis methods, solvothermal synthesis is one of the most effective techniques for obtaining high-purity MOF powders with controlled morphology and crystallinity. This article provides a detailed guide on the solvothermal synthesis process, the required reaction equipment, and key parameters such as temperature and reaction time.

Compared to conventional methods, MSE furnaces offer higher efficiency, lower environmental impact, and improved metal purity, making them ideal for research laboratories and pilot-scale metal production.