When it comes to working at temperatures above 1000°C, what’s happening around your material can be just as important as what’s happening to it. That’s where atmosphere control comes in — a silent, invisible force that shapes everything from material quality to process safety.

What Is “Controlled Atmosphere”?

In high-temperature furnaces, a “controlled atmosphere” means replacing the air inside the chamber with specific gases — or removing the air entirely (vacuum). This helps avoid unwanted chemical reactions like oxidation, contamination, or material degradation.

Common Atmospheres and What They Do

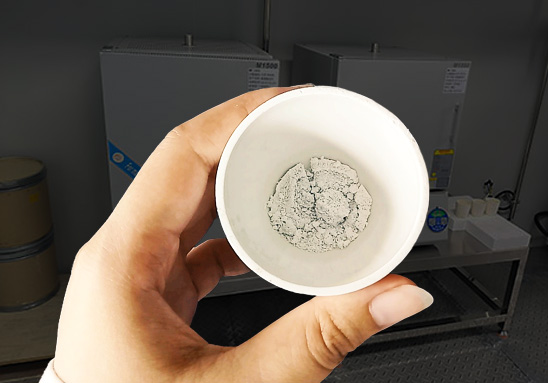

A budget-friendly inert gas used to prevent oxidation. Ideal for metal parts, ceramics, and powder metallurgy.

Even more stable than nitrogen, argon is perfect for high-purity or reactive materials like titanium or rare earths.

By removing all gases, vacuum conditions eliminate oxygen completely — crucial for ultra-pure materials, thermal decomposition, and evaporation processes.

Some processes require a combination — for example, H₂ + N₂ for reducing environments or O₂ + inert gases for controlled oxidation or crystal growth.

Why It’s Not Just “Plug and Play”

Maintaining a stable atmosphere at high temperatures involves several technical challenges:

- Leak-tight chamber design – even a tiny leak can ruin the atmosphere

- Accurate gas flow and pressure control – consistency is key

- Programmable gas switching – some processes need to change atmospheres mid-cycle

- Safety systems – especially when working with flammable or reactive gases

Did You Know?

Even slight changes in oxygen level can dramatically affect the color, strength, or phase of ceramics and metal oxides. That’s why research labs and production lines rely on precise gas control systems.

Atmosphere Control Solutions

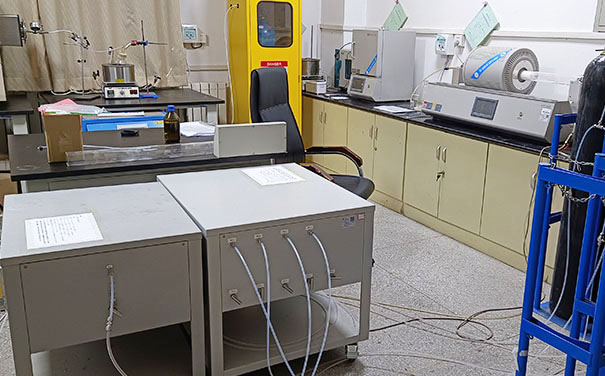

At ZYLAB, we provide more than just high-temperature furnaces. We offer fully integrated atmosphere control solutions — including:

- Single and multi-gas systems

- Gas mixing and switching units

- Vacuum modules

- Real-time monitoring and automation

Whether you’re sintering ceramics, annealing wafers, or running CVD processes, we can help you build the right environment for consistent results.

Contact us to learn more — or ask about our custom solutions.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!

Share this entry

You might also like